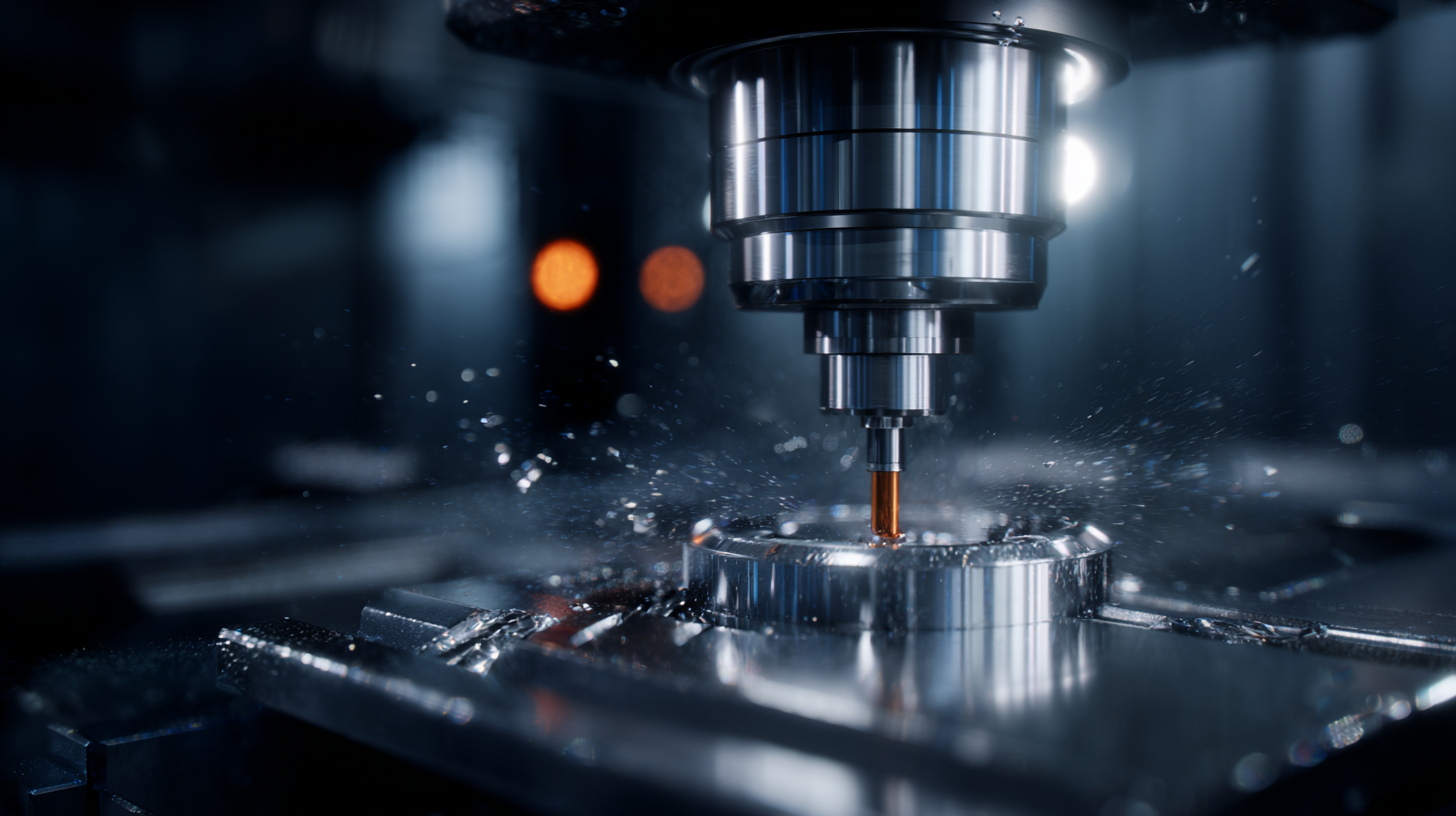

In today's rapidly evolving manufacturing landscape, CNC milling stands out as a pivotal technology driving efficiency and precision. According to a report by Mordor Intelligence, the global CNC machining market is projected to reach USD 100 billion by 2026, with CNC milling accounting for a significant portion of that growth. This surge is largely attributed to the increasing demand for high-quality and intricate designs in various industries, including aerospace, automotive, and medical devices.

As businesses across the globe strive for manufacturing excellence, embracing advanced CNC milling solutions—particularly those offered by leading Chinese manufacturers—has become essential. These solutions not only enhance production capabilities but also contribute to cost-effectiveness and sustainability, making them integral to modern manufacturing strategies. In this blog, we will explore top strategies for leveraging China’s premier CNC milling technologies to achieve superior manufacturing outcomes.

CNC milling has emerged as a crucial pillar in the realm of global manufacturing, contributing significantly to efficiency and precision in production processes. The global CNC machine market is projected to grow strikingly, with an estimated increase from $101.22 billion in 2025 to $195.59 billion by 2032. This represents a robust compound annual growth rate (CAGR) of 9.9% during the forecast period. Such growth underscores the vital role that CNC milling plays in advancing manufacturing capabilities worldwide.

CNC milling has emerged as a crucial pillar in the realm of global manufacturing, contributing significantly to efficiency and precision in production processes. The global CNC machine market is projected to grow strikingly, with an estimated increase from $101.22 billion in 2025 to $195.59 billion by 2032. This represents a robust compound annual growth rate (CAGR) of 9.9% during the forecast period. Such growth underscores the vital role that CNC milling plays in advancing manufacturing capabilities worldwide.

The technology behind CNC milling not only enables the production of intricate components with impeccable accuracy but also enhances the flexibility of manufacturing operations. As industries strive for greater automation and integration of advanced technologies, CNC milling solutions provide the necessary tools to meet rising demands for high-quality and cost-effective products. With the expansion of the market, manufacturers are increasingly leveraging CNC milling to optimize workflows, reduce waste, and improve competitiveness on a global scale. The advancements in CNC technology are pivotal in shaping the future landscape of manufacturing, reinforcing its status as the backbone of global production systems.

China's premier CNC milling machines are at the forefront of modern manufacturing, embodying key features that enhance precision and efficiency. As part of the broader "Made in China 2025" initiative, which emphasizes innovation and high-quality development in manufacturing, these machines are designed to meet the diverse needs of today’s industries. They integrate advanced technology, including high-speed cutting capabilities and automated control systems, which allow for superior accuracy and reduced operational costs. The focus on precision engineering reflects China's commitment to elevating its manufacturing status on a global scale.

Moreover, these CNC milling solutions come equipped with user-friendly interfaces and software, enabling seamless integration into existing workflows. The adaptability of these machines ensures that manufacturers can easily upgrade operations, promoting consistent productivity enhancements. As Chinese companies continue to invest in R&D, the sophistication of CNC technology is set to drive further advancements in sectors ranging from aerospace to medical manufacturing. With ongoing innovations, China solidifies its position as a key player in the global manufacturing landscape, offering solutions that not only compete with but often outperform international alternatives.

In today’s rapidly evolving manufacturing landscape, optimizing production efficiency is paramount for businesses striving for competitive advantage. CNC milling solutions have emerged as a cornerstone technology, enabling manufacturers to enhance precision and reduce lead times. According to a recent report by Research and Markets, the global CNC machining market is projected to reach USD 100 billion by 2025, with a significant portion attributed to advancements in CNC milling technologies.

Implementing these sophisticated CNC milling solutions not only streamlines operations but also contributes to substantial cost savings. The ability to produce complex geometries with higher accuracy reduces material wastage and minimizes the need for time-consuming manual adjustments. A study from Deloitte indicates that manufacturers utilizing CNC technology can achieve processing speed increases of up to 40%, thereby enhancing overall productivity. As Chinese CNC milling solutions continue to innovate, they play a crucial role in driving manufacturing excellence on a global scale, equipping businesses to meet the demands of an increasingly competitive marketplace.

When selecting the right CNC milling machine for your manufacturing needs, it is essential to consider a range of factors that can influence productivity and efficiency. The recent growth in the metal machining market, driven by rising demands from various industries, highlights the importance of investing in high-quality CNC solutions. With an estimated market expansion worth USD 18.43 billion from 2024 to 2028, investing in the right equipment can yield significant returns.

Tips for Choosing CNC Milling Machines:

By carefully considering these factors, manufacturers can better position themselves to leverage CNC technology for optimal productivity and growth.

As global manufacturing continues to evolve, CNC milling technology stands at the forefront, driving innovation and efficiency. According to a report by Grand View Research, the CNC machining market is projected to reach $100 billion by 2027, growing at a CAGR of 8.3%. This expansion underscores the increasing demand for precision and customization in manufacturing processes, particularly in industries such as automotive and aerospace, where complexity and accuracy are paramount.

Emerging trends in CNC milling technology are revolutionizing the landscape of global manufacturing. The integration of artificial intelligence (AI) and machine learning into CNC systems enhances operational efficiency and reduces downtime. A study published by MarketsandMarkets indicates that by 2026, AI-driven manufacturing is expected to generate $10 billion in revenue. Additionally, advancements in materials such as high-performance alloys and composites are enabling manufacturers to achieve unprecedented levels of durability and performance in their products. By leveraging China’s premier CNC milling solutions, manufacturers can not only enhance production capabilities but also position themselves competitively in a rapidly changing market.

| Year | CNC Milling Technology Advances | Production Efficiency (%) | Global Market Share (%) | Sustainable Practices Adoption (%) |

|---|---|---|---|---|

| 2021 | Introduction of AI Integration | 82 | 25 | 30 |

| 2022 | Advancements in Automation | 87 | 30 | 35 |

| 2023 | Hybrid Manufacturing Systems | 90 | 35 | 40 |

| 2024 | Smart Factory Initiatives | 95 | 40 | 50 |