In today's highly competitive manufacturing landscape, selecting the right metal mold manufacturer is crucial to ensuring product quality, efficiency, and cost-effectiveness. According to a recent industry report by MarketsandMarkets, the global mold market is projected to reach USD 51.7 billion by 2025, driven by increasing demand for lightweight and durable materials across various sectors. This growth underscores the importance of sourcing proficient manufacturers capable of meeting specific business needs with precision and innovation.

Additionally, a survey conducted by Statista indicates that 70% of businesses prioritize collaboration and customization in their sourcing decisions. Therefore, understanding the critical attributes to consider when evaluating potential metal mold manufacturers can significantly impact a company's success in harnessing advanced manufacturing technologies and enhancing operational performance.

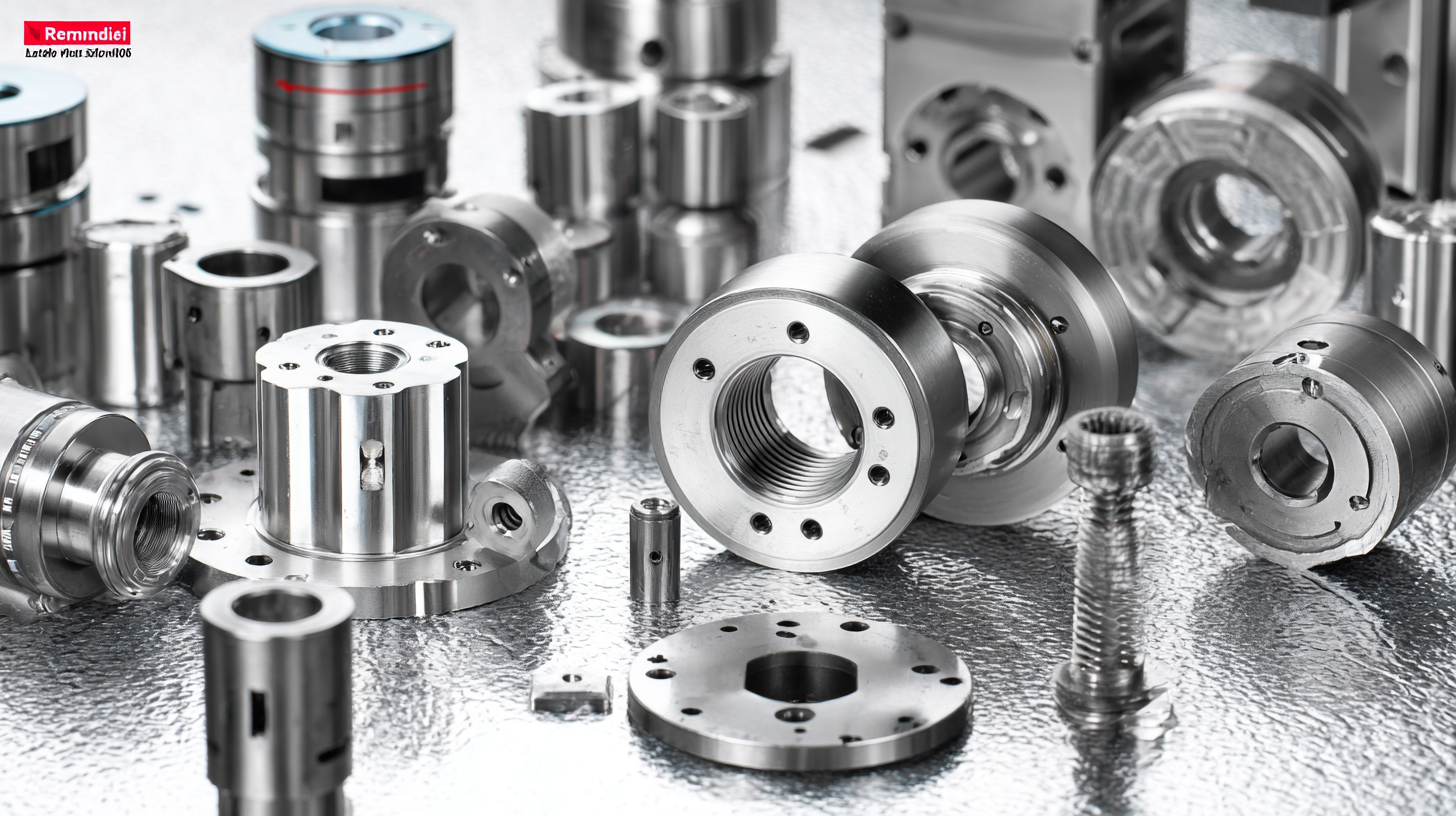

When selecting a metal mold manufacturer for your business needs, several key factors should be evaluated to ensure you make the right choice. One crucial aspect is the manufacturer’s experience and expertise in the specific type of mold required for your projects.

According to the 2023 Metal Industries Report, companies that partner with manufacturers boasting over 10 years of experience in metal molding often report a 25% increase in production efficiency compared to those who choose less experienced providers.

Additionally, quality assurance processes are vital when choosing a manufacturer. A study by the International Association of Mold Makers revealed that manufacturers with ISO certification achieved a defect rate of less than 1%, significantly lower than the industry average of around 3-5%. This reliability not only minimizes production delays but also enhances the quality of the final product.

Lastly, consider the technological capabilities of the manufacturer. Companies that utilize advanced machinery and the latest molding technologies can provide innovative solutions that directly impact the quality and durability of your molds, catering to the increasingly competitive marketplace.

When sourcing metal mold manufacturers, asking the right questions can significantly impact the success of your project. Start by inquiring about the supplier's experience in your specific industry. According to a recent report from Grand View Research, the global metal casting market is expected to reach $210.24 billion by 2026, indicating that expertise in your sector is crucial for meeting industry standards and demands. Understanding their capabilities can help ensure they can deliver molds that not only meet but exceed your requirements.

Additionally, it's essential to ask about their production processes and technology. A study by ResearchAndMarkets highlights that advanced manufacturing technologies, such as 3D printing and CNC machining, are revolutionizing the metal molding industry, allowing for greater precision and faster turnaround times. Ensure that your potential supplier utilizes modern equipment and practices to maintain quality and efficiency. This will help in minimizing production delays and ensuring that the final products align with your expectations.

When evaluating metal mold manufacturers, it’s crucial to assess their capabilities thoroughly to ensure they align with your business needs. Look for manufacturers who utilize state-of-the-art machinery and technology; reports indicate that companies investing in advanced manufacturing technologies can boost production efficiency by up to 30%. This efficiency translates not only into cost savings but also enhances the precision and quality of the molds produced.

Additionally, examining a manufacturer’s experience and expertise in your specific industry is essential. According to a study by the Plastics Industry Association, 70% of companies that engage manufacturers with specialized industry knowledge report higher satisfaction levels with their products. Factors such as material handling capabilities, design expertise, and tooling knowledge should be prioritized. A thorough analysis of previous projects and client testimonials can also provide insights into a manufacturer’s reliability and quality standards, ultimately aiding in your decision-making process.

When sourcing a metal mold manufacturer, the importance of certifications and quality standards cannot be overstated. Certifications like ISO 9001 ensure that manufacturers adhere to rigorous quality management systems, which can significantly reduce the risk of defects and increase customer satisfaction. These standards not only demonstrate a commitment to quality but also enhance the manufacturer's credibility in the marketplace.

**Tips for Evaluating Certifications:**

1. Look for industry-recognized certifications that align with your specific needs. Research the certifying bodies to ensure that their standards are robust and respected.

2. Ask potential manufacturers about their quality control processes and how they maintain compliance with these certifications. A transparent approach indicates a reliable partner.

3. Consider whether the manufacturer can provide documentation of their certifications and any quality audits they have undergone. This information is crucial in assessing their commitment to maintaining high standards.

Incorporating these practices will help ensure that you select a manufacturer that not only meets your production needs but also upholds the quality standards necessary for your business's reputation and success.

| Manufacturer Location | Certifications | Quality Standards | Production Capacity (Units/Month) | Lead Time (Weeks) |

|---|---|---|---|---|

| China | ISO 9001, ISO 14001 | TS16949, ASTM | 5000 | 6 |

| Germany | DIN EN ISO 9001 | ISO/TS 16949 | 3000 | 8 |

| USA | ISO 9001, AS9100 | MIL-STD-810 | 4500 | 4 |

| Japan | ISO 9001, ISO 14001 | JIS Q 9001 | 2500 | 5 |

| India | ISO 9001, ISO 13485 | BS 5750 | 4000 | 7 |

When sourcing a metal mold manufacturer, understanding the balance between cost and value is crucial for optimizing your production processes. According to a report by Grand View Research, the global mold manufacturing market is projected to reach $50 billion by 2028, highlighting the competitive landscape that businesses must navigate. Companies should assess not only the initial pricing of metal molds but also the long-term value that these molds bring to their operations. This involves considering aspects like durability, precision, and the overall efficiency of the manufacturing process.

One effective strategy to measure cost versus value is to evaluate the lifecycle costs of metal molds. Research from MarketsandMarkets indicates that investing in high-quality molds may lead to a reduction in per-part costs over time, due to fewer defects and less downtime. Manufacturers that offer superior materials and craftsmanship often provide molds that withstand rigorous use, ultimately leading to better performance and greater ROI. By carefully analyzing these factors, businesses can make more informed decisions that align cost considerations with the long-term benefits of their mold manufacturing investments.