In the dynamic landscape of manufacturing, selecting the right punching mould manufacturer is crucial for businesses aiming to optimize their production processes and product quality. According to a recent industry report by Market Research Future, the global market for mould manufacturing is expected to reach USD 30 billion by 2025, with a significant portion driven by advancements in automation and precision engineering. As the demand for high-quality molds increases, manufacturers must be equipped with the latest technology and materials to remain competitive.

Moreover, the quality of punching moulds directly impacts the efficiency and effectiveness of production lines. A study from the International Journal of Advanced Manufacturing Technology highlights that improper mould selection can lead to increased operational costs and waste, emphasizing the need for careful consideration when choosing a supplier. With the right punching mould manufacturer, companies can achieve not only enhanced product integrity but also reduced cycle times and increased profitability. This guide aims to provide insights and practical criteria on how to navigate the selection process effectively, ensuring that manufacturers make informed decisions that align with their production goals.

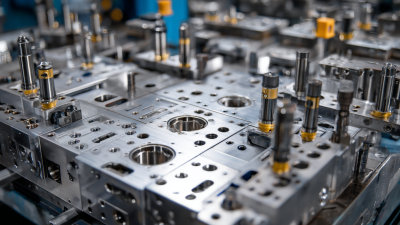

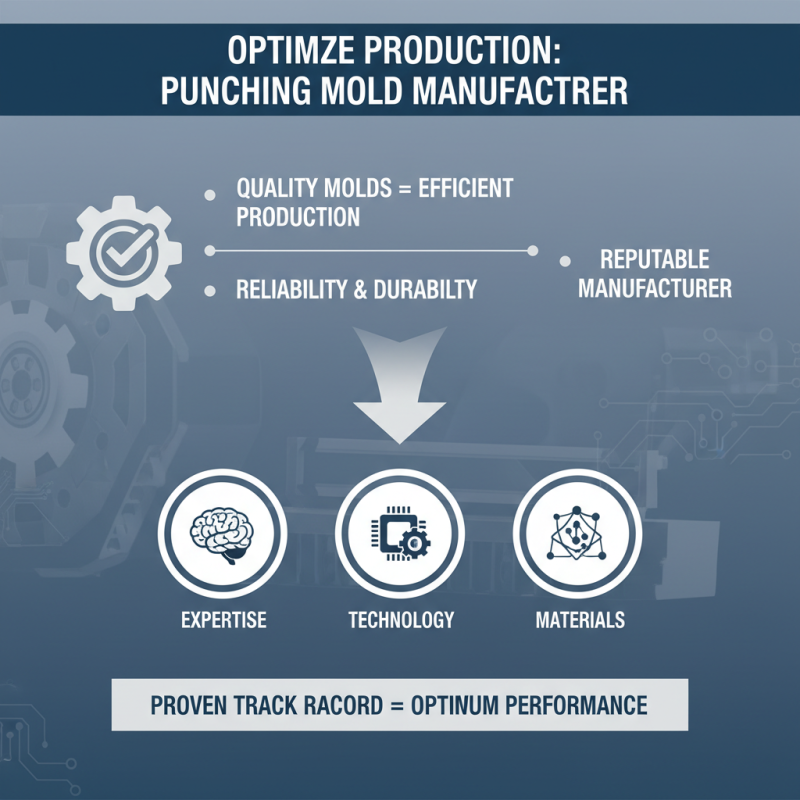

Choosing the right punching mould manufacturer is crucial for ensuring the efficiency and quality of your production processes. A reputable manufacturer not only provides high-quality moulds but also contributes to the overall reliability of your operations. When selecting a manufacturer, it's important to consider their expertise, technology, and the materials they use. A well-established company with a proven track record will have the capabilities to meet your specific requirements, ensuring optimum performance and durability of the moulds produced.

Furthermore, understanding the importance of selecting a quality manufacturer goes beyond just the product itself. A reliable partner can offer valuable insights and support throughout the design and production stages, ultimately influencing your time-to-market and project feasibility. Effective communication and support during the process can lead to better customization and adaptation of moulds to suit your unique needs. Ultimately, investing time and effort in choosing the right punching mould manufacturer can have long-lasting benefits for your business, enhancing productivity and reducing long-term costs associated with subpar products.

When selecting the right punching mould manufacturer, there are several key factors to consider to ensure you make an informed decision. Firstly, evaluate the manufacturer's experience and expertise in the industry. A company with a solid track record and years of experience is likely to understand the nuances of punch manufacturing and can offer innovative solutions tailored to your needs. Look for customer testimonials and case studies that demonstrate their capabilities and the quality of their products.

Another critical factor is the technology and equipment that the manufacturer uses. Advanced machinery and up-to-date technology are essential for producing high-quality punching moulds that meet precise specifications. Consider visiting the manufacturer’s facility if possible, to assess their production processes and quality control measures. Additionally, effective communication and customer service cannot be overlooked. A responsive manufacturer who is willing to collaborate and provide support throughout the design and production process can significantly enhance your experience. Choosing a manufacturer that prioritizes your needs will ultimately lead to a better partnership and successful outcomes for your projects.

This chart illustrates the key factors to consider when choosing a punching mould manufacturer, rated on a scale from 1 to 10 based on their importance. Higher values indicate greater importance in the selection process.

When selecting a punching mould manufacturer, evaluating their expertise and industry experience is paramount. According to a report from the International Mold & Manufacturing Association (IMMA), manufacturers with over 15 years of experience typically produce molds with higher precision and durability. This experience is crucial for ensuring that the designed parts meet stringent quality standards and specifications. Furthermore, experienced manufacturers have established robust quality control processes that significantly reduce the chances of defects and failures.

Another key factor to consider is the range of industries the manufacturer has worked with. Research indicates that manufacturers familiar with diverse sectors—such as automotive, aerospace, and electronics—bring invaluable insights and innovative solutions to the moulding process. The ability to adapt to various technological advancements, as highlighted in a study by the MoldMaking Technology publication, results in improved efficiency and reduced lead times. It's essential to assess case studies or client testimonials to gauge their capability in handling complex projects, as this often reflects their adaptability and skill level in the field.

When selecting a punching mould manufacturer, evaluating their production capabilities and the technology they utilize is paramount. A recent industry report highlights that advanced manufacturing technologies, such as Computer Numerical Control (CNC) machining and high-speed stamping, can enhance precision and efficiency, reducing lead times by up to 30%. Manufacturers that implement these technologies are often able to produce complex designs with tighter tolerances, leading to higher-quality end products.

In addition to technology, the production capabilities of a manufacturer should also be assessed in terms of capacity and scalability. According to a study by the International Association of Mould Manufacturers, companies that have robust production capacities can better handle varying order sizes, from prototyping to large-scale production runs. This flexibility is critical in today's fast-paced market, where demand can shift rapidly. Furthermore, manufacturers that invest in automation often report a 20% increase in production efficiency, allowing them to meet customer demands while maintaining competitive pricing. Understanding these factors can significantly impact the decision-making process in choosing the right partner for your punching mould needs.

| Manufacturer Location | Production Capacity (Units/Month) | Technology Employed | Lead Time (Days) | Certification |

|---|---|---|---|---|

| Asia | 50,000 | CNC Machining, Laser Cutting | 30 | ISO 9001 |

| North America | 20,000 | Stamping, Wire EDM | 45 | ISO/TS 16949 |

| Europe | 35,000 | Progressive Die, Injection Moulding | 60 | ISO 14001 |

| South America | 15,000 | High-speed Stamping, Robotic Welding | 50 | ISO 45001 |

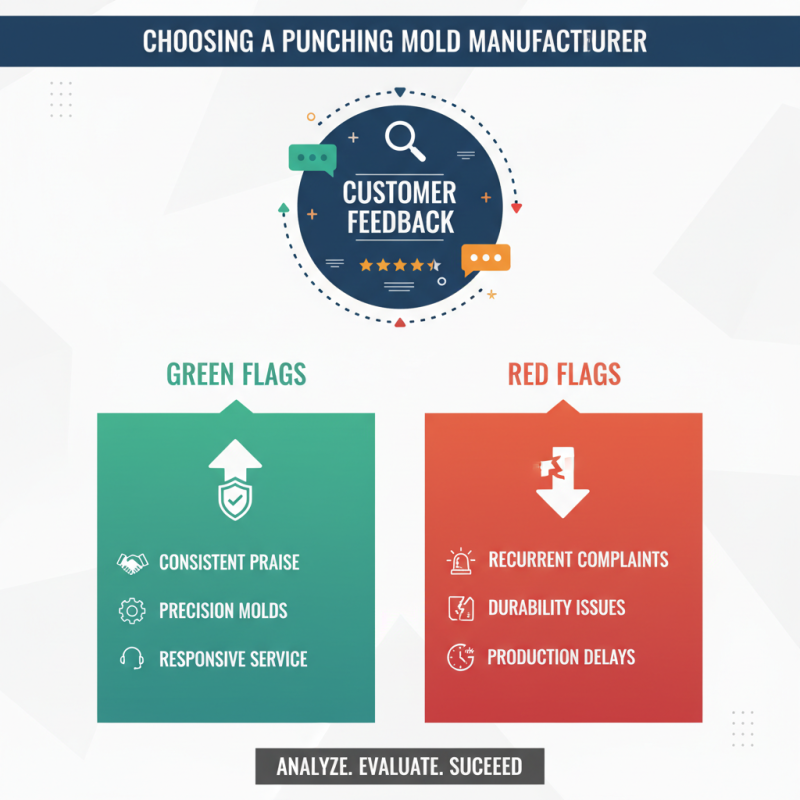

When selecting a punching mould manufacturer, one of the most critical factors to evaluate is customer feedback. Reviews from previous clients can provide valuable insights into the reliability and quality of the manufacturer’s products. Look for patterns in the feedback; consistent praise regarding the precision of the moulds or the responsiveness of customer service can indicate a manufacturer's strengths. Conversely, recurrent complaints, such as issues with durability or delays in production, should raise red flags and warrant further investigation.

Reputation in the market is another key aspect to consider. A manufacturer with a strong and positive reputation often has established a history of good practices and customer satisfaction. This can be assessed through various channels, such as industry forums, trade shows, and professional networks. Engaging with other businesses in your sector can yield recommendations and warn you of potential pitfalls. By thoroughly researching customer feedback and industry reputation, you can make a more informed decision, ensuring that the selected manufacturer aligns with your quality standards and business needs.