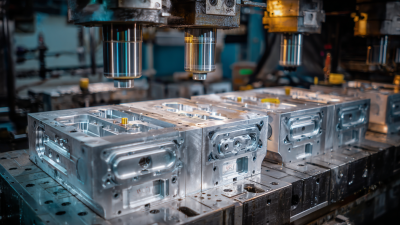

As the manufacturing sector continues to evolve, the importance of innovative moulds cannot be overstated. These pivotal tools not only drive efficiency but also ensure the production of high-quality products at an unprecedented scale. According to Dr. Emily Chen, a leading expert in the mould industry, “The future of manufacturing hinges on our ability to adapt and innovate in the moulds we use; they are the backbone of production processes.” This insight emphasizes the critical role that mould advancements will play in shaping the upcoming landscape of manufacturing.

In 2025, we can expect to witness remarkable breakthroughs in mould technology that will redefine industry standards. From the integration of smart materials to the implementation of automation and digital twin technologies, these innovations promise to enhance productivity, reduce waste, and streamline operations. The potential impact is profound, offering manufacturers a path to not only improve existing processes but also to explore new possibilities in production capabilities.

As we delve into the top five mould innovations set to transform manufacturing in the near future, it becomes clear that staying ahead of these developments is essential for industry players. With experts like Dr. Chen leading the discourse, the mould industry's evolution will be a focal point in ensuring that the manufacturing landscape is not only competitive but also sustainable.

Innovative materials are at the forefront of mould technology advancements, significantly enhancing manufacturing processes. Recent developments in thermoplastics and composite materials have transformed the traditional metal moulds into lighter, more durable alternatives. These advanced materials not only reduce production costs but also improve the efficiency of the moulding process, allowing for quicker turnaround times and increased precision in manufacturing. The incorporation of smart materials, which can adapt to various conditions, also promises to revolutionize how manufacturers approach design and production.

Moreover, the benefits of these innovations extend beyond mere functional enhancements. Sustainable materials, such as biodegradable and recyclable plastics, are being explored, aligning with the industry's growing focus on environmental responsibility. These eco-friendly alternatives minimize waste and reduce the carbon footprint associated with traditional mould materials. By integrating innovative materials into mould technology, manufacturers are poised to create products that are not only high-quality but also sustainable, paving the way for a more environmentally conscious approach to manufacturing in the years to come.

The integration of IoT (Internet of Things) and AI (Artificial Intelligence) in smart moulding is set to revolutionize manufacturing processes. By utilizing connected sensors and devices, manufacturers can gain real-time insights into moulding operations. This connectivity enables predictive maintenance, allowing companies to anticipate equipment failures before they occur, thus minimizing downtime and enhancing productivity. With AI algorithms analyzing data collected from the production line, manufacturers can optimize parameters such as temperature, pressure, and material flow, leading to improved product quality and reduced waste.

Moreover, the shift towards smart moulding encourages a more sustainable approach to manufacturing. IoT devices not only monitor resource usage but also provide analytics that can help identify inefficiencies and areas for energy savings. For instance, by closely monitoring the energy consumption of moulding machines in real-time, manufacturers can adjust operations to reduce their carbon footprint. As companies strive to meet increasing environmental standards, the combination of IoT and AI in moulding processes offers a pathway to more efficient and eco-friendly production, paving the way for a sustainable future in manufacturing.

This chart illustrates the impact of various innovations in moulding technologies on manufacturing processes. The data represents the percentage of companies adopting these technologies by 2025.

In recent years, the manufacturing industry has begun to embrace eco-friendly practices in mould production, reflecting a shift towards sustainability that is increasingly driven by both consumer demand and regulatory changes. According to a report by the International Society of Plastics Engineers, sustainable practices in mould manufacturing can reduce energy consumption by up to 30%, which not only lowers operational costs but also minimizes the environmental impact of production processes. Innovative materials, such as bioplastics and recycled metals, are gaining traction, paving the way for more sustainable mould solutions that meet the rigorous standards of modern industry.

Furthermore, the adoption of advanced technologies like 3D printing and computer-aided design (CAD) is enabling manufacturers to create moulds with reduced waste and enhanced precision. A study by the American Mold Builders Association highlighted that implementing 3D printing in mould production can decrease material usage by as much as 40%, while significantly accelerating the prototyping phase. These innovations not only support eco-friendly initiatives but also enhance the overall efficiency of the manufacturing process, leading to a more sustainable future in the moulding industry. As manufacturers prioritize sustainability in their operations, embracing these innovations will be essential for staying competitive in an evolving marketplace.

| Innovation | Description | Sustainability Impact | Applicable Industries |

|---|---|---|---|

| Biodegradable Mould Materials | Utilizing materials that decompose naturally. | Reduces plastic waste and environmental impact. | Consumer Goods, Packaging |

| 3D Printing for Moulds | Additive manufacturing techniques for precise mould creation. | Minimizes material waste during production. | Automotive, Aerospace, Medical |

| Recycled Composite Materials | Using recycled plastics and composites in mould production. | Promotes a circular economy and reduces resource extraction. | Electronics, Building Materials |

| Energy-Efficient Moulding Machines | Machines designed for lower energy consumption. | Significantly decreases carbon footprints. | General Manufacturing, Food Industry |

| Smart Mould Technology | Integration of IoT for real-time monitoring of mould conditions. | Improves efficiency and reduces material waste. | All Manufacturing Sectors |

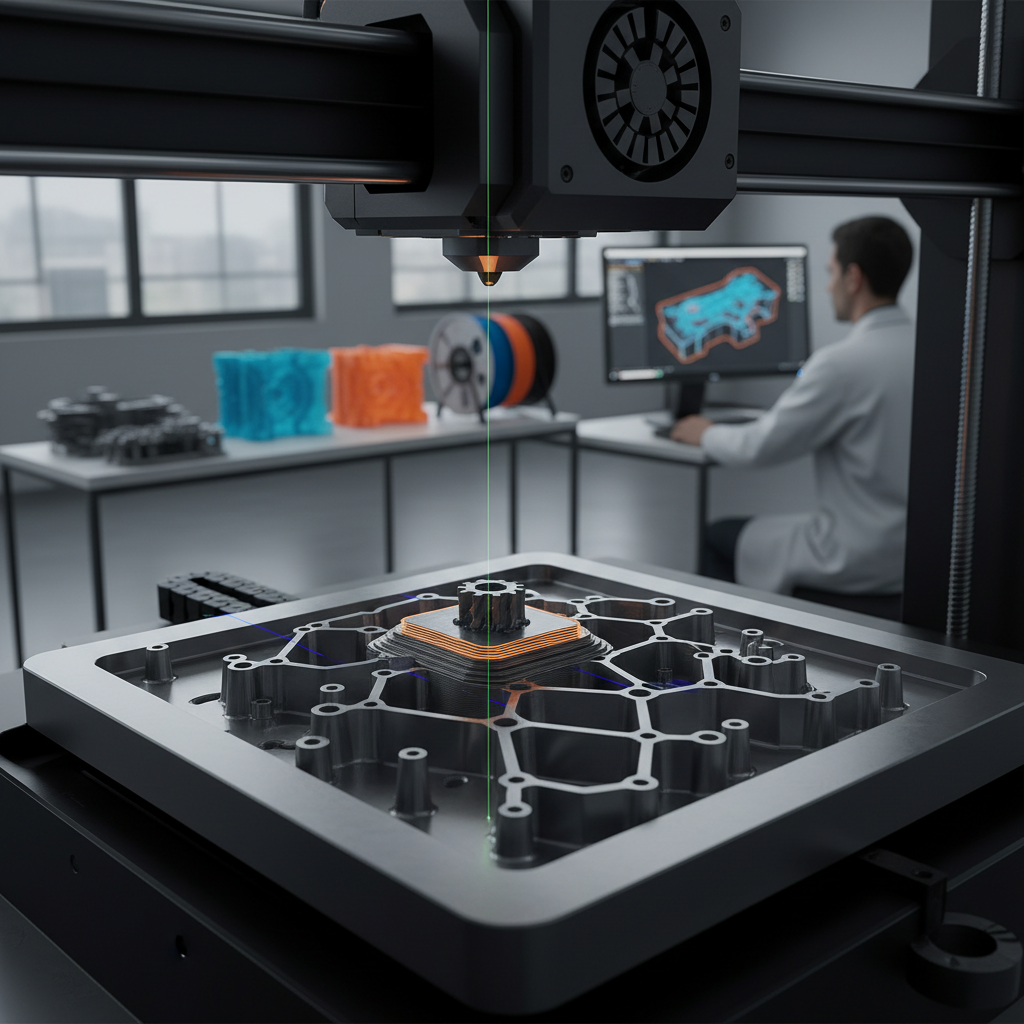

The rise of 3D printing technology is transforming mould design, bringing unprecedented precision and efficiency to the manufacturing sector. Traditionally, mould creation has involved extensive manual processes and prototyping, resulting in high costs and long lead times. However, with the advent of additive manufacturing, designers can now create complex geometries with intricate details that were previously impossible to achieve. This innovation not only streamlines the design process but also significantly reduces material waste, as 3D printing allows for precise layer-by-layer construction.

Moreover, 3D printing in mould design facilitates rapid prototyping, enabling manufacturers to test and iterate their designs swiftly. This agility fosters innovation, allowing companies to respond more effectively to market demands and customize products to meet specific client needs. As manufacturers continue to embrace this cutting-edge technology, mould production is set to become faster and more cost-efficient, ultimately reshaping the future of manufacturing and positioning businesses for success in a competitive landscape. The integration of 3D printing into mould design is a pivotal step towards achieving a more sustainable and responsive manufacturing process.

The landscape of mould production is rapidly evolving with the integration of automation technologies, significantly enhancing speed and reducing costs. According to a report by MarketsandMarkets, the global automation market in manufacturing is projected to grow from $169 billion in 2020 to $275 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.5%. This surge illustrates how vital automation has become in achieving efficiency and competitiveness in the mould manufacturing sector.

One of the most transformative innovations in this space is the use of robotic process automation (RPA) in mould production. RPA can handle repetitive tasks such as material handling and quality inspections at speeds unattainable by traditional methods. A study from Deloitte indicates that organizations implementing RPA can reduce operational costs by up to 30%. Additionally, real-time data analysis enabled by automation technologies helps manufacturers optimize production lines and minimize waste, further driving down costs and enhancing product quality.

Furthermore, the rise of additive manufacturing, or 3D printing, is reshaping how moulds are designed and produced. According to Wohlers Associates, the additive manufacturing industry is expected to grow to nearly $40 billion by 2024. This technology allows for rapid prototyping and the creation of more complex mould designs that were previously impossible or too costly. The ability to quickly iterate designs not only speeds up the production process but also enhances flexibility in responding to market demands. Such advancements highlight the crucial role of automation in revolutionizing mould production and setting the stage for future manufacturing innovations.