Choosing a reputable metal mold manufacturer is a critical step in optimizing your production needs, ensuring the highest quality and efficiency in your manufacturing process. When you partner with a trusted manufacturer, you tap into a wealth of expertise, experience, and resources that can significantly enhance your product quality and production speed. Not only do these manufacturers utilize advanced technology and high-grade materials, but they also implement rigorous quality control measures to guarantee that each mold produced meets the highest industry standards. This results in reduced waste, lower costs, and improved performance of your final products. In this blog post, we will explore the key benefits of collaborating with a reliable metal mold manufacturer, highlighting how their industry knowledge and commitment to excellence can transform your production capabilities and drive your business success.

In the metal mold manufacturing industry, reputation plays a crucial role in determining the quality of products and services provided by manufacturers. According to a report by Grand View Research, the global metal molding market is projected to reach USD 70.33 billion by 2025, underscoring the importance of selecting a reputable manufacturer to ensure that production needs are met efficiently and effectively. A company with a solid reputation typically adheres to stringent quality control standards and invests in advanced technology, directly impacting the durability and precision of the molds produced.

Tip: When evaluating potential metal mold manufacturers, consider checking their certifications and past client testimonials. These indicators can provide insights into their reliability and quality.

Furthermore, a reputable manufacturer often has extensive experience across various industries, allowing them to better understand specific requirements and challenges. For example, a study published by the Journal of Materials Processing Technology highlights that companies with experienced manufacturers report up to 30% lower error rates in production. This efficiency not only saves time but also reduces costs associated with waste and rework.

Tip: Engage with potential manufacturers during the selection process. Ask about their experience in your industry to gauge their capability and reliability in addressing your unique production challenges.

When selecting a metal mold manufacturer, evaluating quality standards and certifications is crucial to ensuring your production meets industry benchmarks. A reputable manufacturer will typically hold certifications such as ISO 9001, which reflects their commitment to quality management systems. According to a report by the International Organization for Standardization, companies with ISO certifications can experience up to a 30% increase in operational efficiency, highlighting the impact of adhering to rigorous quality standards.

Furthermore, manufacturers that comply with the American Society for Testing and Materials (ASTM) standards demonstrate their ability to meet specific material and performance requirements. Data from a survey conducted by the Metalworking Manufacturing & Services Association indicates that 85% of manufacturers prioritize working with certified suppliers, as this reduces the risk of defects and improves product reliability. By choosing a manufacturer that upholds these certifications, you are not just investing in products but also fostering a partnership that prioritizes quality and performance in your production processes.

Choosing a reputable metal mold manufacturer can significantly impact your production costs over time. While it may seem tempting to opt for cheaper alternatives, the long-term savings from reliable manufacturers often outweigh initial expenditures. Quality molds lead to fewer defects, reducing waste and rework. This efficiency not only streamlines production but also minimizes material costs and enhances overall productivity.

Tips for Maximizing Cost Efficiency:

By making informed choices, you can ensure that your production needs are met with efficiency, reliability, and impressive cost-effectiveness.

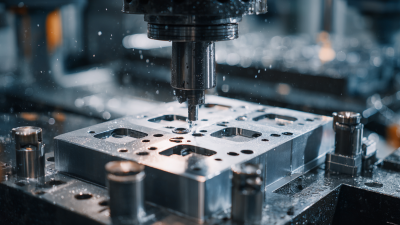

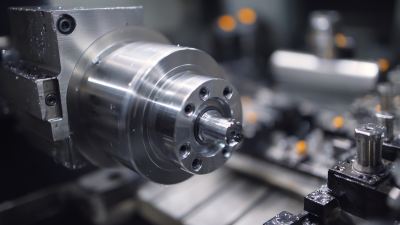

The impact of advanced technology on metal mold production efficiency is significant, particularly in the realm of precision engineering and manufacturing. As industries increasingly shift towards automation and sophisticated methodologies, the use of advanced technologies such as the Taguchi method and Analysis of Variance (ANOVA) becomes essential. These techniques not only optimize injection molding parameters but also address common issues such as weight reduction and warpage in PET preforms. By systematically analyzing variations and identifying optimal settings, manufacturers can enhance production efficiency, reduce material waste, and ensure high-quality outputs in their metal mold processes.

Furthermore, advancements in processes like Metal Injection Molding (MIM) underscore the importance of integrating innovative technologies for improved outcomes. By enhancing the integrity of polymer binders and optimizing their interaction with metal powders, MIM enables the creation of intricately designed parts with exceptional accuracy. As the market for metal casting continues to expand, driven by technological advancements and rising demand, utilizing reputable manufacturers adopting these technologies will play a crucial role in maintaining competitiveness and achieving operational excellence in production. Embracing these technological shifts not only streamlines production but also contributes to the overall sustainability of manufacturing practices.

| Dimension | Traditional Methods | Advanced Technology | Efficiency Gain (%) |

|---|---|---|---|

| Production Speed | 300 units/day | 600 units/day | 100% |

| Material Waste | 10% | 4% | 60% |

| Initial Setup Time | 3 days | 1 day | 67% |

| Precision Level | ±0.5 mm | ±0.01 mm | 98% |

| Cost Efficiency | $5/unit | $3/unit | 40% |

When selecting a reputable metal mold manufacturer, assessing customer support and service should be a primary focus. Effective communication is key to ensuring that your production needs are met. A manufacturer with a strong customer support system can provide timely responses to inquiries, updates on project progress, and solutions to any problems that arise. This level of engagement fosters a relationship built on trust, allowing for smoother project execution and potential collaboration on future endeavors.

Tips for choosing the right manufacturer include evaluating their responsiveness before you even place an order. Do they return your calls promptly? Are they clear and detailed in their responses? Additionally, consider their proactive approach to service. A manufacturer that offers regular check-ins during production can help identify and resolve potential issues early, reducing downtime and ensuring efficiency in your project timeline.

Moreover, look for manufacturers leveraging data to enhance operational efficiency. Companies that utilize data analytics in their production systems typically show superior performance in areas such as supply chain management and quality control. By partnering with a manufacturer that prioritizes these practices, you're more likely to receive high-quality, timely products that meet your specific needs.