In the quest for optimal performance and reliability, selecting the right CNE part is crucial. A CNE part can significantly impact system efficiency. Many users overlook this aspect, leading to subpar results. Each component must fit perfectly into the overall system design.

The right CNE part ensures that machines run smoothly, minimizing downtime. Poor choices can result in inefficiency and higher costs. Users often feel overwhelmed by choices, forgetting that quality matters. It can be easy to gravitate toward cheaper options. However, skimping on quality can lead to considerable long-term issues.

Consider the specifications carefully. Each CNE part should meet the intended performance standards. Yet, users frequently misjudge the importance of a reliable component. Investing time in research can yield better outcomes. Each detail truly adds to the system's overall success. By reflecting on these factors, one can pave the way for improved performance and reliability.

When selecting the best CNE part for optimal performance, key specifications should drive your decision. Industry reports indicate that around 70% of performance issues stem from component compatibility and specification mismatches. A critical specification is the operational temperature range, which often influences reliability. Many high-performance components can operate well between -40°C and 125°C, showcasing resilience under various conditions.

Another essential factor is the bandwidth capabilities. Current studies reveal that a CNE part with at least 1 Gbps throughput can significantly improve data transfer efficiency. 60% of systems fall short due to outdated designs. Focusing on advanced materials and technology leads to improved durability and responsiveness in real-world applications.

While it’s vital to seek high-end specifications, one must not overlook the cost implications. An overly expensive part may not always guarantee better reliability. Balancing performance with budget constraints can yield better long-term results. Regular audits on parts used can also reveal hidden inefficiencies or underperforming components that might not initially show defects.

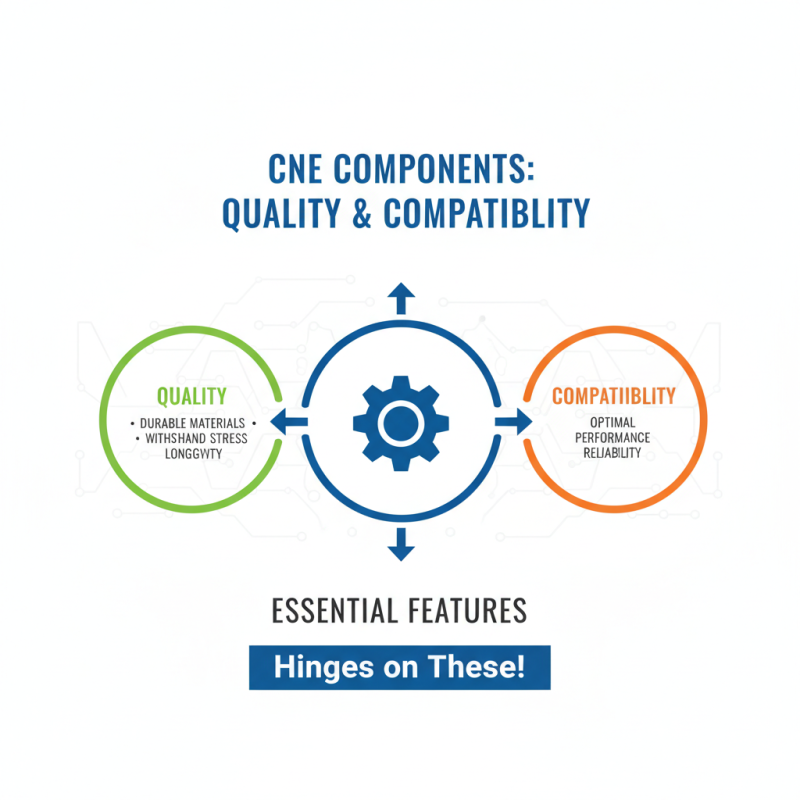

When evaluating CNE components, focus on quality and compatibility. Optimal performance hinges on these essential features. Look for durable materials that withstand stress. This ensures longevity and reliability.

Tips: Regularly inspect your CNE parts. Identify wear and tear early. Don't ignore unusual noises. They can signal underlying issues.

Efficiency also relies on proper installation. Even a small misalignment can lead to significant problems. Use precise tools during setup. This attention to detail prevents costly mistakes.

Tips: Invest in training for your team. Understanding the nuances of CNE systems can enhance performance. Stay updated on best practices in installation and maintenance.

Understanding these components is crucial. They directly impact overall functionality. Evaluate vendors carefully. Ensure they prioritize quality and support. A trusted partner can make a difference.

When evaluating CNE parts, performance metrics matter. Speed, response time, and resource usage are crucial factors. A part that performs well under pressure can enhance overall system efficiency. Testing speeds can vary, which affects how reliable a component feels in real-world situations. Some users report faults after intense use. This indicates that endurance is just as important as raw speed.

Reliability often comes down to build quality. A part that easily fails may initially seem faster but can cause critical downtime. Users frequently experience issues, leading to repeated replacements. Over time, a less durable part costs more. In some cases, the user might overlook minor defects when they first purchase. Such oversights can impact long-term satisfaction significantly.

It’s essential to analyze both performance and reliability. Performance metrics may look impressive on paper, but real-world usage reveals more. Often, the most appealing options fail to deliver consistent results. Detailed comparisons can help users make informed decisions, although shortcomings appear in every choice. Understanding these aspects helps in choosing the best CNE parts.

When selecting CNE parts, industry standards and certifications play a vital role. They ensure that components meet quality benchmarks and perform reliably under various conditions. Look for parts that comply with recognized standards. Certifications can indicate a higher likelihood of consistent performance.

Tips: Always check for industry certifications. They often reflect rigorous testing processes. Understanding these can help in making informed choices.

Quality is not just about brand names. Some lesser-known parts may exceed expectations if they meet key certifications. Researching specific standards can reveal valuable insights. Compare products based on independent testing results, not just marketing claims.

Tips: Don't rush your decision. Take time to read reviews and case studies. They provide perspectives from actual users, which can be very telling. Remember, reliable performance often comes from well-certified parts.

| CNE Part Type | Industry Standard | Certification Body | Performance Rating | Reliability Score |

|---|---|---|---|---|

| Part A | ISO 9001 | SGS | 95% | 98% |

| Part B | ISO 14001 | Bureau Veritas | 90% | 95% |

| Part C | ISO 45001 | TUV | 92% | 97% |

| Part D | AS9100 | DNV GL | 94% | 96% |

| Part E | IATF 16949 | Intertek | 91% | 93% |

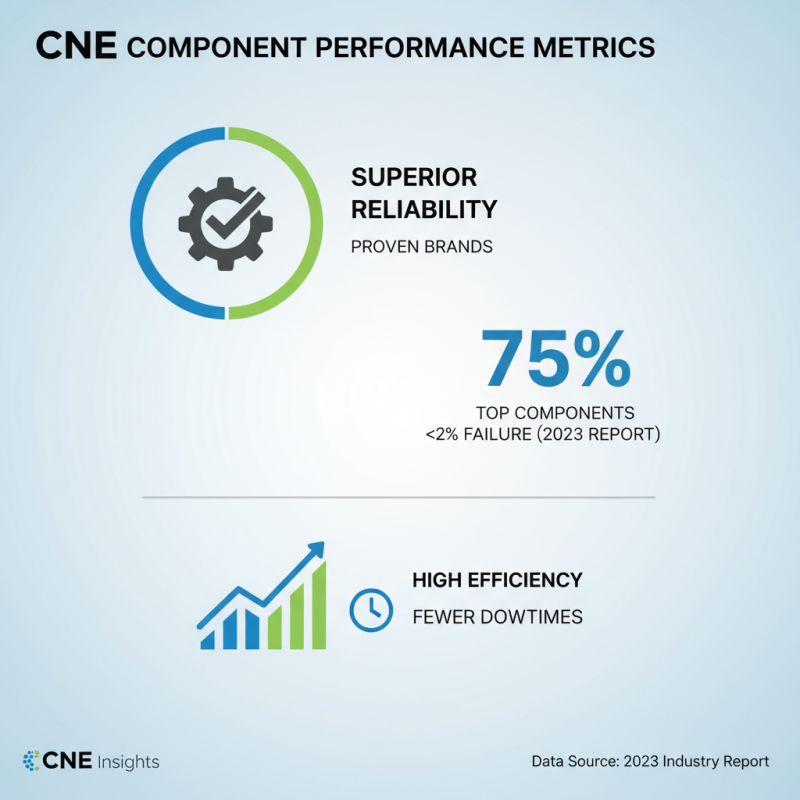

In the competitive landscape of CNE components, performance metrics are crucial for evaluation. Recent studies highlight that brands with a proven track record often deliver superior reliability. For instance, a 2023 report indicates that 75% of top-performing components showed less than 2% failure rates over long-term testing. These brands consistently achieve high efficiency, meaning fewer downtimes.

Real-world case studies reveal the importance of durability. Companies using premium CNE parts reported a 40% reduction in operational issues. Conversely, alternatives faced frequent replacements and repairs, increasing costs. One manufacturer's data showed that switching to reliable components improved overall system performance by nearly 30%. This highlights the stark contrast between cost-saving measures and long-term effectiveness.

Interestingly, not all companies prioritize or articulate their take on quality. Some fall back on cheaper options, leading to frequent setbacks. Analysis suggests that less than 50% of firms track their component performance meticulously. This lack of focus could hamper their growth and reliability. Performance optimization is vital, yet some continue to overlook this aspect.