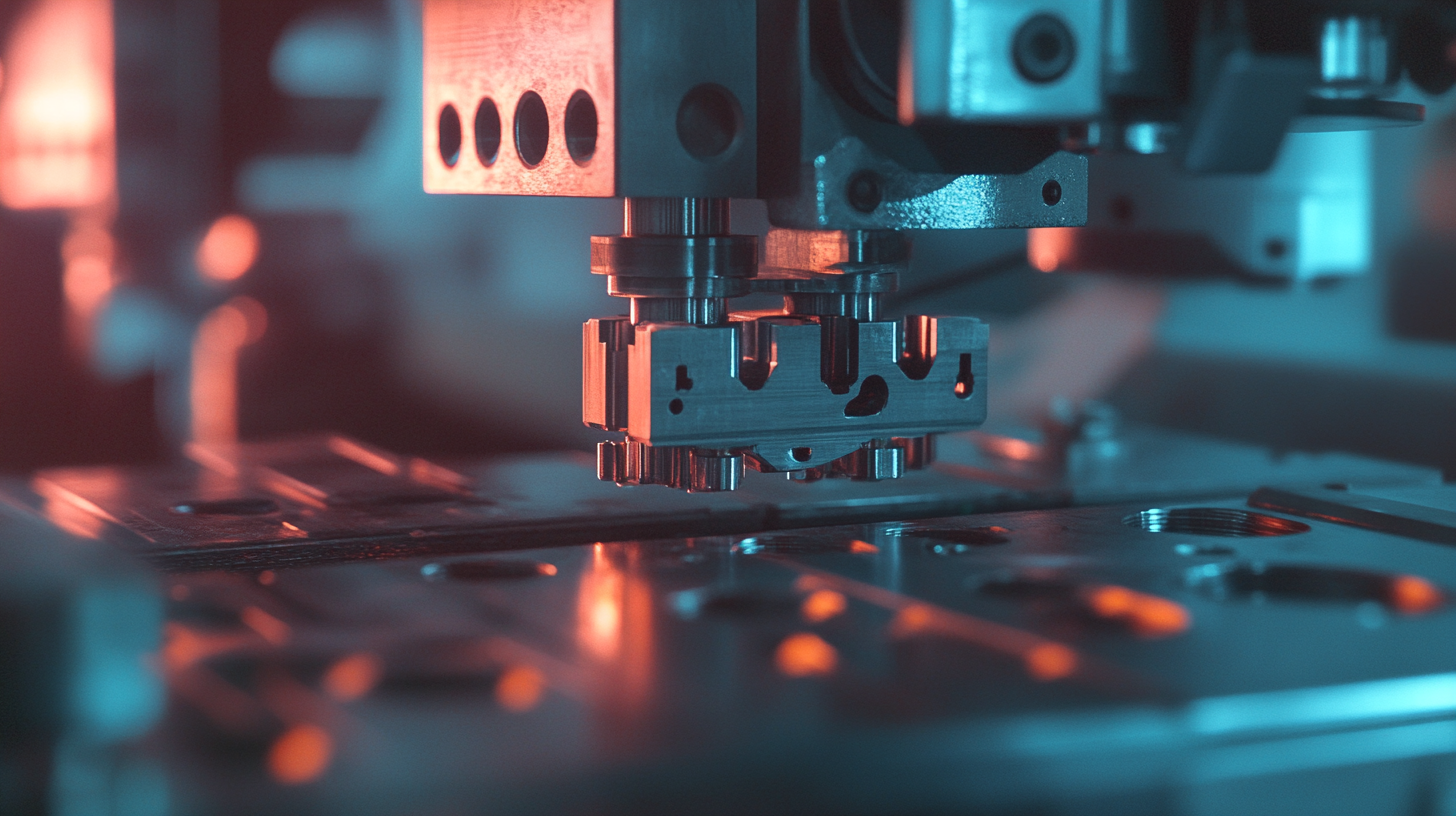

In the fast-evolving landscape of manufacturing, the choice of tools can significantly impact the efficiency and quality of production. Among these tools, the stamping die emerges as a critical component that can redefine operational excellence. According to a report by Grand View Research, the global stamping dies market is expected to reach USD 10.4 billion by 2025, growing at a CAGR of 4.8%. This underscores the rising demand for precision and versatility in manufacturing processes across various sectors, including automotive, aerospace, and electronics. The effectiveness of a stamping die is not merely defined by its design but also by its ability to cater to diverse product characteristics and applications. Understanding the nuances of different types of stamping dies and their optimal utilization can be a game changer, enabling manufacturers to enhance productivity while maintaining stringent quality standards.

The evolution of stamping die technology has significantly transformed the manufacturing landscape, pushing the boundaries of efficiency and precision. Traditionally, stamping dies were designed with limited capabilities, often leading to prolonged setup times and decreased production volume. However, recent advancements, such as progressive stamping dies and automated die-changing systems, have reshaped this sector. According to a report by Smithers, the global market for stamping die technology is expected to reach $18.6 billion by 2025, representing a robust compound annual growth rate (CAGR) of 5.2%.

Modern stamping dies are equipped with innovative materials and advanced design techniques, allowing for enhanced durability and performance. The shift towards computer-aided design (CAD) and simulation technologies has enabled manufacturers to create dies that not only reduce material waste but also shorten production lead times.

A survey conducted by the Precision Metalforming Association shows that 70% of manufacturers believe that incorporating the latest stamping die technologies has led to a noticeable improvement in their operational efficiency. As companies continue to adopt these advancements, they position themselves to meet the growing demands of various industries, including automotive and electronics, thereby solidifying their competitive edge in the market.

In modern manufacturing, the choice of stamping die can significantly impact cost efficiency and production effectiveness. As industries increasingly adopt advanced stamping technologies, understanding the differences between traditional and advanced stamping dies becomes essential. Advanced stamping dies are designed to accommodate the complexities of modern materials, such as titanium-based alloys, enabling manufacturers to produce high-quality components with less waste and shorter lead times.

When considering the transition to advanced stamping dies, manufacturers should evaluate their current processes. One effective tip is to analyze your production flow to identify bottlenecks. Implementing advanced dies can streamline operations and enhance overall productivity. Additionally, investing in digital design applications can facilitate continuity across development phases, further reducing time and costs related to product development.

Another important tip is to regularly assess the cost implications of your stamping processes. Advanced dies may require higher initial investment but can lead to substantial long-term savings through increased efficiency and reduced material waste. By fostering partnerships that focus on innovation in die design and materials, manufacturers can stay ahead of market trends and maintain a competitive edge in their respective industries.

When considering the factors that contribute to the effectiveness of stamping dies in manufacturing, the choice of material—specifically, steel versus aluminum—plays a pivotal role in overall performance. According to a report by Grand View Research, the global metal stamping market is projected to reach $300 billion by 2025, highlighting the significant demand for high-quality stamping dies that can enhance efficiency and reduce production costs. Steel stamping dies are known for their superior strength and durability, enabling them to withstand high-pressure applications and extended production runs. In fact, research from the Precision Metalforming Association indicates that steel dies can last up to five times longer than their aluminum counterparts in high-volume scenarios.

On the other hand, aluminum stamping dies offer advantages in terms of weight reduction and cost efficiency, making them particularly appealing for industries where rapid prototyping and lower material costs are crucial. A study published in the Journal of Manufacturing Processes found that aluminum dies can be produced more quickly and at a lower initial investment, which can lead to faster turnaround times for manufacturers.

As businesses strive to remain competitive in an increasingly fast-paced market, the choice between steel and aluminum stamping dies ultimately hinges on the specific production needs, material constraints, and desired output quality, making this a critical consideration for manufacturers aiming for optimal performance.

When it comes to manufacturing, precision and tolerance are paramount, especially regarding the choice of stamping dies. Different die types offer varying levels of accuracy in the production process, and understanding these differences can significantly impact your operations. High-quality stamping dies can deliver tolerances as tight as ±0.001 inches, which is essential for industries that require exact specifications, such as automotive and aerospace. This level of precision ensures that components fit together seamlessly, reducing waste and the risk of costly errors during assembly.

Moreover, the choice of die material and design plays a crucial role in determining its performance. For instance, dies made from high-speed steel or carbide tend to maintain their integrity under extreme stress, allowing for higher production rates without compromising quality. Additionally, the flexibility of advanced die technologies, like progressive dies, allows for complex part geometries with minimal rework, enhancing overall efficiency.

Ultimately, investing in the right stamping die not only elevates the manufacturing quality but also streamlines the production process, making it a game changer for businesses looking to stay competitive in their markets.

In the world of manufacturing, the effectiveness of stamping dies can significantly influence production quality and efficiency. One outstanding example comes from an automotive parts supplier that implemented advanced stamping dies designed for high-volume production. By utilizing precision-engineered dies, the company reduced material waste and minimized cycle times, resulting in a 30% increase in productivity. This transition not only improved their output but also enhanced the overall quality of the components produced, demonstrating the crucial role that the correct stamping die plays in manufacturing success.

Another case study highlights a consumer electronics manufacturer that faced challenges with inconsistent part dimensions. After investing in custom stamping dies, the company experienced a remarkable transformation. The new dies allowed for tighter tolerances and consistently uniform parts, which are vital for the intricate assemblies required in electronics. This upgrade not only streamlined their production process but also led to significant cost savings due to fewer defects and the reduction of rework needs. These real-world applications underline how strategic investments in stamping die technology can lead to substantial improvements in manufacturing outcomes.

| Case Study | Industry | Die Type | Key Benefits | Performance Improvement |

|---|---|---|---|---|

| Case Study A | Automotive | Progressive Die | Increased precision, reduced waste | 30% increase in production speed |

| Case Study B | Electronics | Compound Die | Lower production costs, enhanced durability | 20% reduction in material costs |

| Case Study C | Aerospace | Single-Stage Die | Improved safety, lightweight components | 15% weight reduction on components |

| Case Study D | Consumer Goods | Transfer Die | Flexibility in design, rapid changes | 25% quicker design iterations |