In the rapidly evolving landscape of manufacturing, selecting the right punching mould manufacturer is crucial for optimizing production efficiency. According to a report by MarketsandMarkets, the global die and mould market is projected to reach USD 98.25 billion by 2025, driven by the increasing demand for precision-engineered components across various industries. The efficiency of production largely hinges on the quality and capabilities of the chosen manufacturer, as inadequate moulds can lead to longer cycle times and increased operational costs. As industries push for higher productivity and lower waste, understanding the intricacies of punching mould manufacture becomes essential for businesses aiming to stay competitive. Ensuring a partnership with a skilled manufacturer not only enhances manufacturing efficiency but also significantly contributes to the overall product quality and market readiness.

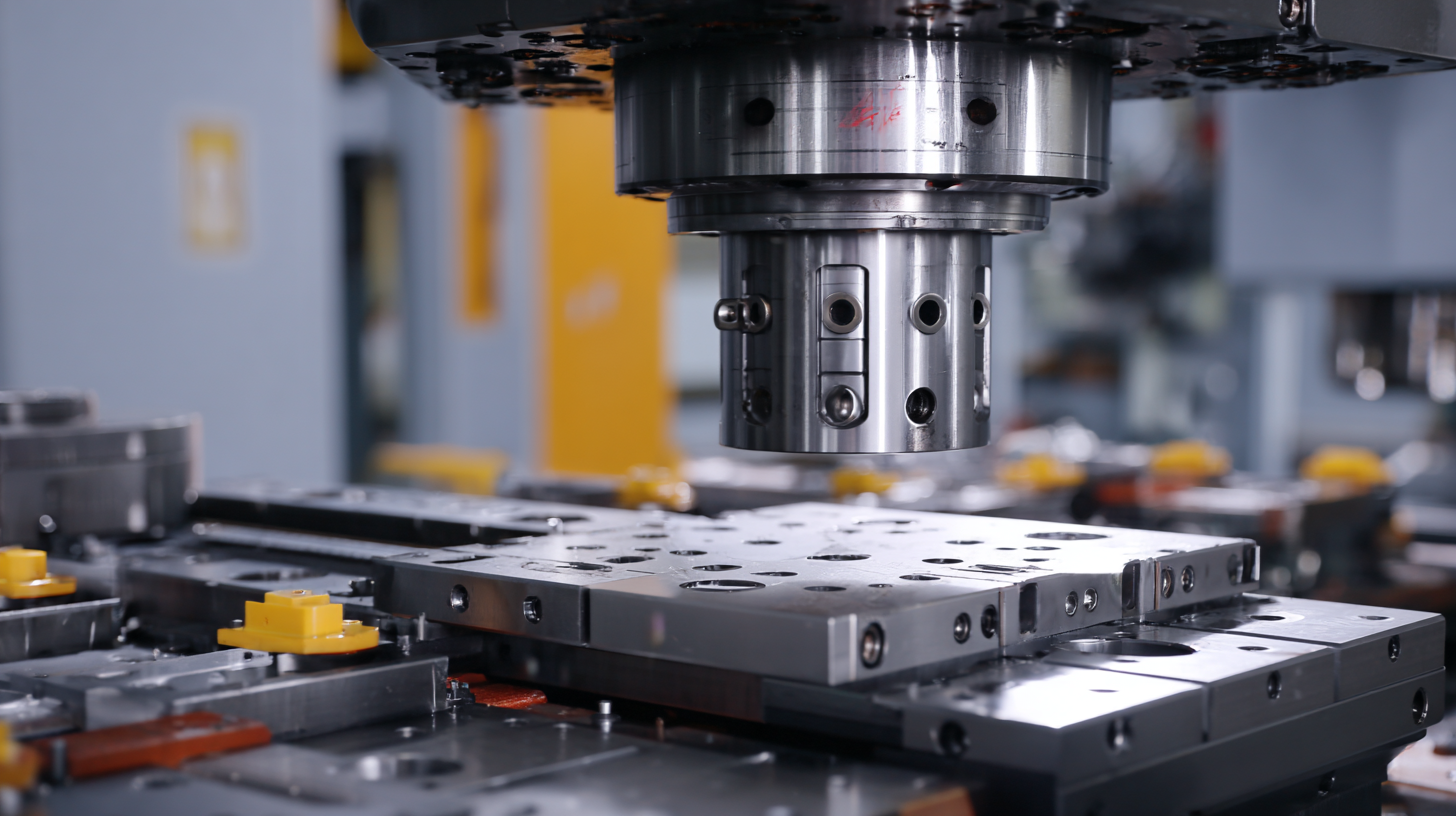

When selecting a punching mould manufacturer, it's essential to establish clear criteria that ensure optimal production efficiency. Start by assessing the manufacturer's experience and expertise in the specific type of mould you require. A company with a proven track record can significantly reduce risks associated with quality and reliability, as they are familiar with the nuances of the production process.

Another critical factor is the capacity to handle your production needs. Just as investors must determine their goals when building a portfolio, businesses must evaluate their manufacturing capabilities against their projected demands. This includes assessing the manufacturer's capacity for expansion, as well as their ability to adapt to changing market conditions. A flexible manufacturer can provide the necessary support during periods of growth, ensuring your production timelines remain uninterrupted.

Lastly, consider the manufacturer's approach to innovation and technology. The integration of advanced manufacturing techniques can lead to increased efficiency and reduced costs, ultimately impacting your bottom line. By prioritizing these key criteria in your selection process, you can align your operational strategy with a partner that enhances your overall production performance.

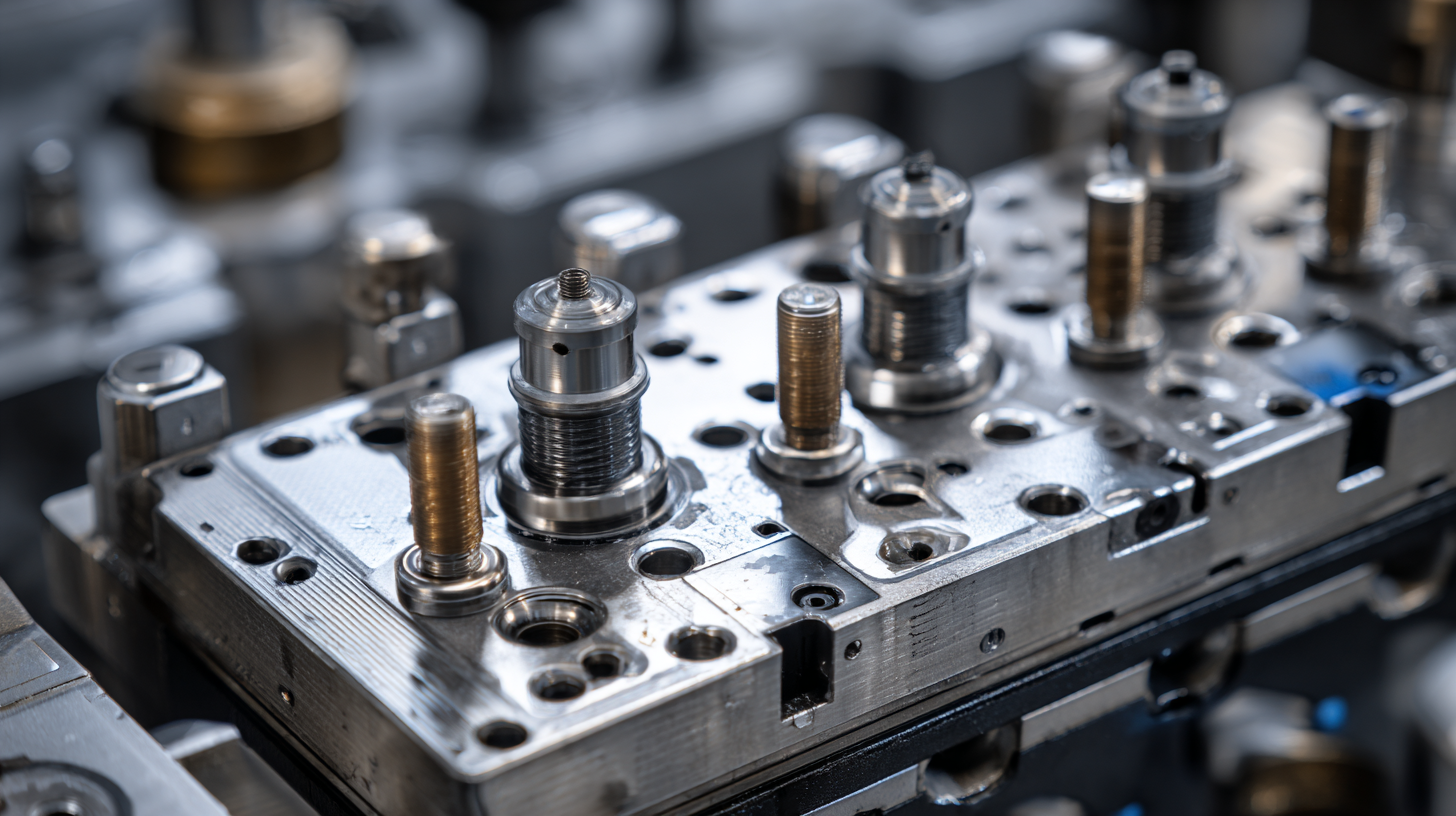

When selecting a punching mould manufacturer, one of the most critical factors to consider is their industry knowledge and experience. A manufacturer with extensive experience in the field is more likely to understand the nuances and specific requirements of your production needs. Their familiarity with different materials, tooling techniques, and production processes can significantly contribute to the efficiency and quality of the final product. Knowledgeable manufacturers can offer valuable insights and suggestions, ensuring that your project is executed smoothly and aligns with industry standards.

When selecting a punching mould manufacturer, one of the most critical factors to consider is their industry knowledge and experience. A manufacturer with extensive experience in the field is more likely to understand the nuances and specific requirements of your production needs. Their familiarity with different materials, tooling techniques, and production processes can significantly contribute to the efficiency and quality of the final product. Knowledgeable manufacturers can offer valuable insights and suggestions, ensuring that your project is executed smoothly and aligns with industry standards.

Moreover, manufacturers with a strong background in the industry can quickly identify potential challenges and provide effective solutions. Their expertise allows them to anticipate issues that less experienced manufacturers might overlook, leading to costly delays and inefficiencies. By evaluating a manufacturer’s past projects and client testimonials, you can gauge their capability and reliability. An established manufacturer not only brings technical expertise but also a deeper understanding of market trends and customer demands, ultimately resulting in a more optimized production process that meets your specific requirements.

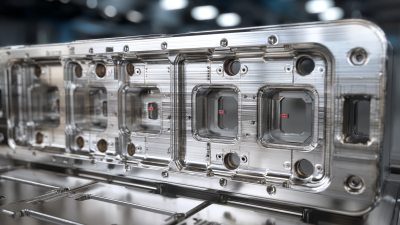

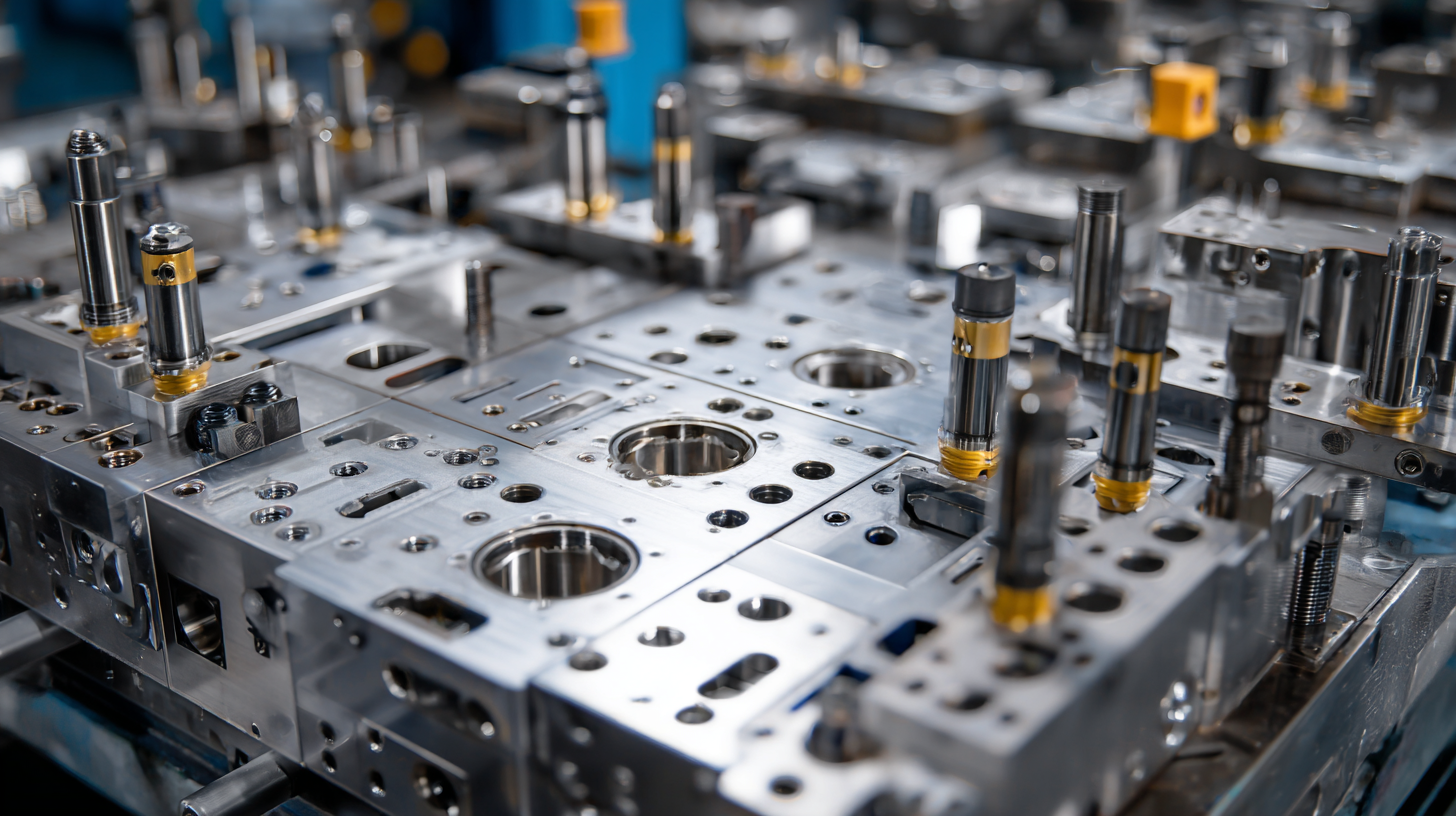

When selecting a punching mould manufacturer, understanding their production capabilities is crucial for optimizing both efficiency and quality. Different manufacturers offer varying levels of technology, experience, and resources, which directly impact their capacity to meet specific project demands. It's essential to analyze the machinery and equipment they utilize; advanced CNC machines and automated processes tend to yield higher precision and consistency, reducing the margin for error and enhancing overall production speed.

Moreover, a manufacturer’s adaptability to different materials and design complexities can significantly influence the outcome of your production line. Assessing their past projects and capabilities in handling diverse specifications will provide insight into their expertise and reliability. Manufacturers that can demonstrate a strong track record of delivering high-quality moulds across various applications are often better positioned to meet your efficiency goals. By taking the time to compare these aspects, you can ensure that your chosen partner will not only meet your immediate needs but also contribute to long-term operational success.

When selecting a punching mould manufacturer, customer support and communication skills are critical factors that can significantly influence production efficiency. A manufacturer’s ability to respond promptly and effectively to inquiries can streamline the decision-making process. Whether you have technical questions about materials or require updates on production timelines, a responsive support team can facilitate smoother operations and mitigate potential delays.

Moreover, clear communication is vital throughout the manufacturing process. A good manufacturer will not only provide regular updates but will also ensure that technical specifications and production requirements are understood and met. This includes discussing design modifications, addressing concerns promptly, and offering insight into potential challenges. By choosing a manufacturer that prioritizes strong communication and customer service, you can foster a collaborative partnership that enhances problem-solving and drives production efficiency.

| Manufacturer Location | Production Capacity (Units/Month) | Lead Time (Weeks) | Customer Support Rating (1-5) | Communication Skills Rating (1-5) | Technical Expertise (1-5) |

|---|---|---|---|---|---|

| Asia | 5000 | 6 | 4 | 5 | 4 |

| Europe | 3000 | 8 | 5 | 4 | 5 |

| North America | 4000 | 4 | 3 | 5 | 4 |

| South America | 2000 | 10 | 4 | 3 | 3 |

| Australia | 1500 | 12 | 2 | 4 | 2 |

When selecting a punching mould manufacturer, the balance between cost and quality is crucial for optimal production efficiency. The US metal forging market, valued at $7.75 billion in 2022 with a projected CAGR of 6.1%, reflects the growing demand for high-quality moulds that can meet diverse production needs. Companies must carefully assess potential manufacturers not only on pricing but also on the quality of materials used, such as steel or aluminum, and the manufacturing processes employed, whether manual or machine-based.

Exploring these factors helps in identifying a manufacturer that supports both cost-effectiveness and durability. Mould quality directly impacts production efficiency; subpar moulds can lead to increased waste and downtime. Therefore, conducting thorough research and considering long-term benefits over short-term savings will ensure that manufacturers achieve their production goals without compromising on quality. A strategic approach in evaluating mould suppliers can significantly enhance a company’s competitive edge in the market.