Choosing the right fabrication services for your project is a critical step that can significantly influence the overall success of your endeavor. Whether you are working on a complex industrial project or a simple custom design, understanding the various factors that contribute to effective fabrication is essential.

Different projects have unique requirements, and selecting a service provider that aligns with these needs can enhance efficiency, improve quality, and potentially reduce costs. This guide aims to outline key considerations, such as

material selection, technological capabilities, and the importance of proven expertise, to help you identify the most suitable fabrication services for your specific project goals.

By carefully evaluating these elements, you can ensure that your project not only meets but exceeds expectations, turning your vision into reality with the right partner in fabrication.

Choosing the right fabrication services for your project is a critical step that can significantly influence the overall success of your endeavor. Whether you are working on a complex industrial project or a simple custom design, understanding the various factors that contribute to effective fabrication is essential.

Different projects have unique requirements, and selecting a service provider that aligns with these needs can enhance efficiency, improve quality, and potentially reduce costs. This guide aims to outline key considerations, such as

material selection, technological capabilities, and the importance of proven expertise, to help you identify the most suitable fabrication services for your specific project goals.

By carefully evaluating these elements, you can ensure that your project not only meets but exceeds expectations, turning your vision into reality with the right partner in fabrication.

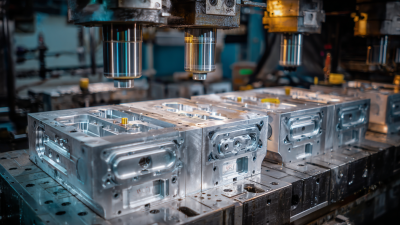

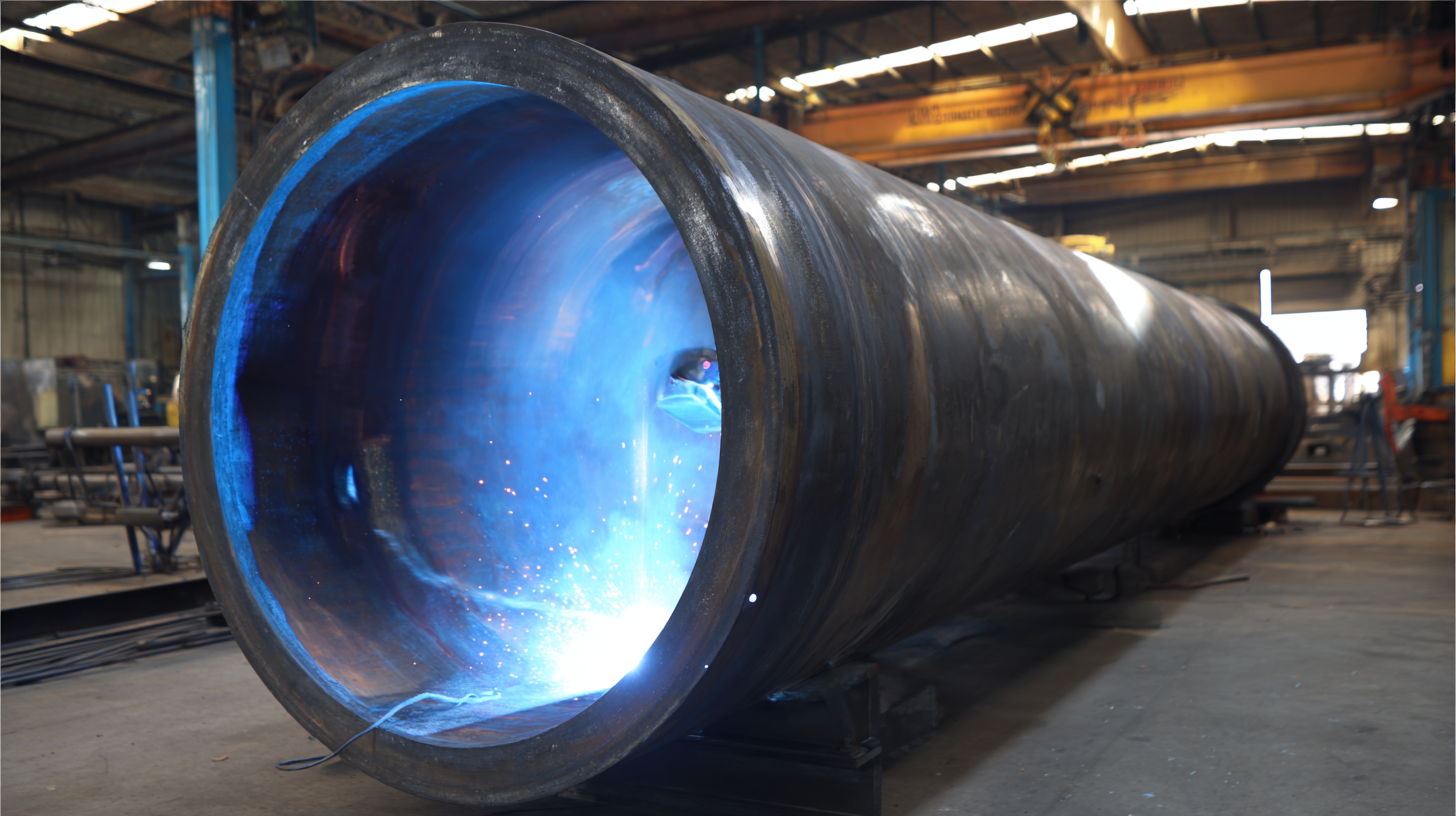

When selecting fabrication services for your project, the first step is to clearly identify your specific project requirements. Consider the type of materials you will be using, as certain fabrication services specialize in particular materials such as metal, plastic, or wood. Understanding the properties of these materials and how they fit with your project goals is crucial. Additionally, think about the complexity of the design; if your project entails intricate designs or tight tolerances, seek out services that have a strong reputation in precision engineering.

Another important aspect to evaluate is the scale of your project. Are you looking for a small batch production or a large scale manufacturing run? Different fabrication services may excel in one over the other. Furthermore, take into account the timeframe for your project. Timely delivery is often essential, so it's important to communicate your deadlines clearly. Lastly, consider the level of customization you require; some services may offer more flexibility in design alterations than others. By thoughtfully assessing these elements, you can choose fabrication services that align seamlessly with your project needs.

When selecting fabrication services for your project, evaluating the experience and expertise of the providers is crucial. Experienced fabricators not only possess the technical skills necessary for quality output but also have a deep understanding of industry standards and best practices. Review their past projects to gauge their capability. A provider with a diverse portfolio is often more adept at addressing various challenges that may arise during fabrication, ensuring that your specific needs are met effectively.

Moreover, expertise in the relevant materials and fabrication techniques can significantly impact the outcome of your project. Ensure that the providers have specialists who are knowledgeable about the latest advancements in fabrication technology and methods. Asking about their qualifications and certifications can offer insight into their commitment to quality and continuous improvement. Engaging in discussions with your potential fabricators about their processes can help you assess their problem-solving abilities and overall approach, which are essential for successful collaboration.

When selecting fabrication services for your project, understanding the materials and techniques involved is crucial for achieving optimal results. According to the "2023 Global Manufacturing Report," over 70% of manufacturers prioritize the choice of material as a key factor influencing the overall quality and durability of their products. Different materials such as metals, plastics, and composites offer varying properties that can significantly affect functionality and cost-efficiency. For instance, aluminum alloys are favored for their lightweight and strength, while stainless steel is often preferred for its corrosion resistance, particularly in industrial applications.

In terms of fabrication techniques, innovations in technology have introduced advanced methods like CNC machining, laser cutting, and 3D printing. The "North American Fabrication Industry Study" highlights that businesses utilizing CNC machining can achieve precision levels up to 0.005 inches, which is critical for high-tolerance components. Meanwhile, 3D printing is rapidly gaining traction, with reports indicating that the market for additive manufacturing is expected to grow by 26.4% annually through 2028. This growth signals a shift toward more complex designs that were previously unattainable. By carefully comparing materials and fabrication techniques, project managers can ensure their designs not only meet specifications but also offer sustainability and cost-effectiveness in the long run.

When selecting fabrication services for your project, assessing quality control measures is paramount. Quality control ensures that every aspect of the fabrication process meets your standards and specifications, ultimately affecting the final product's integrity and performance. Inquire about the service provider's quality control protocols, including the use of industry-standard testing methods, certifications, and adherence to regulations. A rigorous quality control process not only reduces the risk of defects but also enhances overall efficiency by identifying issues before they escalate.

Moreover, it's beneficial to explore the materials and technologies employed in the fabrication process. Reliable services often utilize advanced equipment and tools that facilitate precision and consistency. Understanding the quality of raw materials also plays a crucial role in the fabrication outcome. Engaging with a service that prioritizes quality control, from initial design to final inspection, can significantly contribute to the success of your project, ensuring that the end product not only meets but exceeds expectations.

When selecting fabrication services for your project, understanding the cost factors involved is crucial for effective budget management. According to a recent report by Deloitte, nearly 70% of project failures can be traced back to poor budget planning and unforeseen expenses. Therefore, it is essential to break down the costs into categories such as materials, labor, and overhead. For instance, raw material prices can fluctuate significantly; as noted in a 2023 pricing index by the Metal Service Center Institute, metal prices have surged by 15% year-on-year, impacting overall project budgets.

Moreover, labor costs represent a significant portion of fabrication service expenses, often accounting for 20-30% of the total budget. The Bureau of Labor Statistics states that skilled labor shortages have led to increased wage rates in the manufacturing sector, contributing further to project costs. By understanding these factors, project managers can develop a more accurate financial forecast and identify areas where cost reductions may be possible. Prioritizing a detailed cost analysis can help ensure that the chosen fabrication services align with project constraints, leading to more successful outcomes.

| Service Type | Average Cost ($) | Lead Time (days) | Quality Rating (1-5) | Customer Feedback (%) |

|---|---|---|---|---|

| Metal Fabrication | 2500 | 14 | 4.5 | 90 |

| Plastic Fabrication | 1800 | 10 | 4.2 | 85 |

| Sheet Metal Work | 2200 | 12 | 4.7 | 92 |

| Welding Services | 2000 | 8 | 4.8 | 95 |

| Prototype Manufacturing | 3500 | 20 | 4.6 | 89 |