When it comes to manufacturing, selecting the right stamping parts is crucial for optimizing production efficiency and product quality. According to a report by the Grand View Research, the global metal stamping market size was valued at approximately $239 billion in 2021 and is expected to witness a compound annual growth rate (CAGR) of 4.5% from 2022 to 2030. This growth highlights the critical role that stamping parts play in various industries, including automotive, aerospace, and electronics, where precision and durability are paramount.

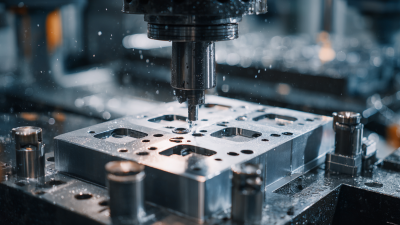

In addition to understanding market trends, manufacturers must consider the specific requirements of their projects, including material selection, tolerance levels, and production volume. A study by IBISWorld indicates that businesses in the metal stamping sector are increasingly adopting advanced technologies such as automation and computer numerical control (CNC) machining, which further underscores the need for thoughtfully chosen stamping parts that align with modern manufacturing processes. By making informed decisions, companies can enhance their operational efficiency, reduce costs, and maintain a competitive edge in a rapidly evolving marketplace.

When it comes to choosing the right stamping parts for your manufacturing needs, understanding your specific requirements is crucial. This involves a thorough analysis of the materials you plan to work with, the functional specifications of your stamped parts, and the environment in which they will be used. Ensure that you consider factors such as tensile strength, corrosion resistance, and thermal properties, as these will directly impact the performance and longevity of the parts in your final product.

Tips: Always create a detailed list of your manufacturing requirements before beginning the sourcing process. This list should include dimensions, tolerances, and any surface finish requirements. Additionally, engage with your design and engineering teams to ensure that the stamping parts align with your overall production goals.

Another important factor to consider is the production volume. High-volume production may allow for cost-effective mass stamping processes, while low-volume needs might benefit from precision stamping methods that provide flexibility without sacrificing quality. By aligning the manufacturing process with your volume requirements, you can achieve both efficiency and cost-effectiveness in your projects.

Tips: Evaluate sample parts from potential suppliers to test for quality, fit, and function. This hands-on approach will help you identify any potential issues before making larger commitments, ensuring that your stamped parts meet the necessary specifications for your manufacturing needs.

When selecting stamping parts for manufacturing, it's essential to consider several key factors that can significantly impact the final product's performance and efficiency. First and foremost, the material of the stamping parts should be assessed based on the application's requirements. Common materials include steel, aluminum, and brass, each providing distinct benefits in terms of strength, weight, corrosion resistance, and cost. Understanding the application will guide decisions regarding the appropriate material choice to ensure that the parts can withstand operational stresses.

Another critical factor is the intricacy of the part design. Complicated shapes may require advanced stamping techniques and greater precision, which can influence both manufacturing costs and lead times. Therefore, evaluating the complexity of the desired components is crucial. Companies should also consider the production volume, as this will determine the best method for prototyping and mass production. High-volume needs may justify the investment in specialized stamping equipment, whereas low-volume requirements might be better served with more versatile manufacturing options. Aligning these factors will help manufacturers select the right stamping parts that meet both performance criteria and budget constraints effectively.

| Factor | Description | Importance Level (1-5) |

|---|---|---|

| Material | The type of material used for stamping affects durability and cost. | 5 |

| Tolerance | The precision required for the stamped parts, impacting fit and function. | 4 |

| Production Volume | Estimated quantity of parts needed, influencing cost-effectiveness. | 5 |

| Lead Time | Time required to manufacture and deliver the stamped parts. | 4 |

| Cost | Budget considerations that impact material choice and production methods. | 5 |

| Surface Finish | Quality of the surface affecting aesthetics and corrosion resistance. | 3 |

| Application | Industry and application of the parts which dictate specific requirements. | 5 |

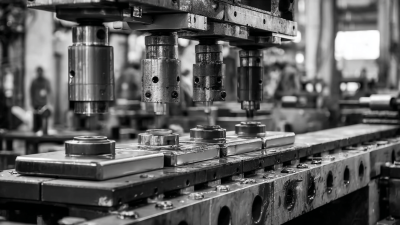

When selecting stamping parts for manufacturing needs, understanding the various stamping processes is crucial. Key methods include progressive stamping, deep drawing, and transfer stamping, each serving distinct applications and offering unique benefits.

Progressive stamping is often used for high-volume production due to its efficiency; it allows multiple operations to be performed in a single stroke, minimizing scrap material and maximizing output. This method is particularly suitable for producing complex parts with tight tolerances.

On the other hand, deep drawing is ideal for creating deep, cylindrical shapes from sheet metal. This process involves pulling the metal into a die to form the desired shape, making it excellent for items such as containers and automotive components. The deep drawing technique requires precise control of material flow and tooling to prevent wrinkling or tearing.

Lastly, transfer stamping is valuable for intricate components requiring multiple forming steps, where parts are moved from one station to another. This process is advantageous for creating large parts with complex geometries, ensuring high accuracy and repeatability. Understanding these processes will help manufacturers choose the most suitable option for their specific applications and production goals.

When it comes to selecting the right stamping parts for manufacturing, one of the most crucial factors to consider is the material used. Materials such as steel, aluminum, and brass each offer distinct advantages depending on the application. According to a report by the International Association of Machinists and Aerospace Workers, steel is favored for its strength and durability, making it suitable for heavy-duty parts. On the other hand, aluminum is celebrated for its lightweight properties and resistance to corrosion, which can enhance efficiency in industries like automotive and aerospace.

When evaluating material options, it's essential to consider factors such as tensile strength, elongation, and surface finish. A study published by the Society of Manufacturing Engineers found that parts made from specialized alloys can improve operational performance. For instance, high-strength low-alloy (HSLA) steel can offer superior mechanical properties while reducing weight. This makes HSLA a popular choice in sectors requiring both strength and lighter components.

Tips: Always conduct a thorough analysis of the environment in which the stamping part will operate. Consider factors like temperature extremes, chemical exposure, and load conditions, as these will influence material selection. Additionally, keep in mind cost-effectiveness; while some materials may be pricier upfront, their longevity and reduced maintenance requirements can lead to lower overall expenses. Leveraging software tools for material selection can also help streamline the decision-making process, ensuring you choose the best option for your specific needs.

When selecting stamping parts for manufacturing, assessing the capabilities of potential suppliers is crucial. A thorough evaluation starts with understanding their equipment and technology. Suppliers should possess modern, well-maintained machinery that can accommodate the specific requirements of your projects. It's essential to inquire about their production capacity, lead times, and flexibility in adapting to changes. These factors will determine whether they can meet your demands consistently without compromising on quality.

In addition to equipment assessment, it's imperative to review the quality standards adhered to by the supplier. Look for suppliers that have established quality management systems, such as ISO certifications. These certifications demonstrate a commitment to maintaining high standards throughout the production process. Regular quality checks, testing protocols, and adherence to industry-specific regulations are key indicators of a supplier's reliability. Engaging with suppliers who prioritize quality assurance will ensure that the stamping parts you receive meet your specifications, ultimately enhancing the efficiency and dependability of your manufacturing operations.