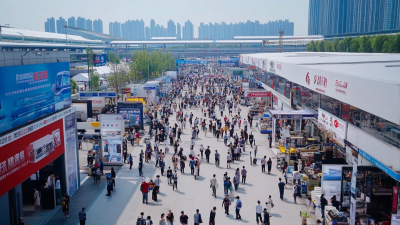

In today's fiercely competitive business landscape, selecting the right manufacturer is more than just a logistical decision; it is a pivotal factor that can significantly impact a company's success. According to a report by IBISWorld, the manufacturing sector accounts for approximately 11.3% of the GDP in the United States, underscoring its critical role in the economy. The right manufacturer can enhance product quality, optimize supply chain efficiency, and ultimately contribute to higher customer satisfaction and loyalty.

Moreover, the global manufacturing market is expected to reach a staggering $2.5 trillion by 2025, as noted in a recent McKinsey & Company analysis. This growth emphasizes the need for businesses to align themselves with reliable manufacturers that can scale operations and adapt to evolving market demands. Companies that prioritize strategic partnerships with manufacturers not only mitigate risks associated with production delays and quality control issues but also position themselves for long-term growth and sustainability in an ever-changing market landscape. Thus, the choice of manufacturer is a crucial decision that can create a ripple effect throughout all facets of a business, shaping its trajectory toward success.

The selection of the right manufacturer significantly influences business performance and can be a key determinant of success in a competitive market. According to a 2022 report by McKinsey & Company, companies that carefully choose their manufacturing partners can reduce costs by up to 20% while also improving product quality. Moreover, they found that businesses with strong supplier relationships are 50% more likely to experience sustainable growth. This data indicates that the implications of manufacturer selection extend beyond immediate financial benefits, encompassing long-term strategic advantages.

Furthermore, a study by Deloitte highlighted that manufacturers who prioritize collaboration and innovation with their partners can enhance their operational efficiency by 30%. When manufacturers and businesses align on shared goals, they create an ecosystem that fosters agility and responsiveness to market changes. In an era where supply chain disruptions are increasingly common, the right manufacturing partner can not only safeguard against risks but also lead to enhanced customer satisfaction and loyalty. Thus, businesses must invest time in evaluating potential manufacturers, focusing on those who can contribute positively to performance metrics and overall business success.

Choosing the right manufacturer is crucial for ensuring the success of your business, particularly in the competitive cookie market. The global cookie market is projected to reach a size of approximately USD 45 billion by 2025, growing at a CAGR of about 5.6% from 2020 to 2025. When selecting a manufacturer, it is important to consider several key factors such as product type, distribution channels, and flavor preferences.

For instance, cookies are categorized into regular, sweet, and savory options, appealing to diverse consumer tastes. Regular cookies hold a significant share, but the rise of chocolate and savory cookies indicates shifting market trends. Distribution strategies also play a vital role; supermarkets and specialty stores have seen substantial growth, reflecting changing consumer shopping habits. As more businesses look for reliable manufacturers, evaluating these factors becomes imperative to align with market demands and enhance competitive advantages.

| Key Factors | Importance Level | Impact on Business |

|---|---|---|

| Quality Control | High | Ensures product reliability and customer satisfaction |

| Production Capacity | Medium | Affects ability to meet demand spikes |

| Cost Efficiency | High | Impacts profit margins |

| Location | Medium | Influences shipping costs and delivery times |

| Experience and Reputation | High | Affects trust and future collaborations |

| Flexibility and Responsiveness | Medium | Critical in adapting to market changes |

When selecting a manufacturer, assessing their reliability and reputation is paramount. A manufacturer’s reliability reflects their ability to meet deadlines, maintain quality standards, and respond effectively to unforeseen challenges. To evaluate this, businesses should examine past performance through reviews, testimonials, and case studies from previous clients.

Engaging with existing customers can provide valuable insights into the manufacturer's operational practices and dependability, thereby aiding in identifying potential risks before entering into a contract.

Reputation, on the other hand, encompasses the manufacturer's standing within the industry and their commitment to ethical practices. A well-regarded manufacturer typically adheres to regulatory standards and prioritizes sustainability.

Conducting thorough background checks and seeking third-party certifications can help gauge their credibility. Additionally, participating in industry forums and networking events can offer firsthand experiences from peers, allowing businesses to make informed decisions that align with their operational goals and values.

By focusing on these aspects, companies can forge partnerships that contribute positively to their long-term success.

Effective communication and collaboration are critical components in establishing successful relationships with manufacturers. According to a report by McKinsey & Company, companies that invest in strong communication practices achieve 20% higher productivity than their competitors. By fostering a culture of open dialogue, businesses can ensure that their needs and expectations are clearly understood, thus minimizing the risk of errors and delays in production.

Furthermore, collaboration can significantly enhance innovation in product development. A study by Deloitte found that organizations engaged in collaborative relationships with their manufacturers are 50% more likely to introduce new products to the market successfully. This synergy not only accelerates the development process but also allows for the pooling of resources and expertise, leading to higher-quality outcomes. By prioritizing communication and collaboration, businesses can build resilient partnerships that contribute to their long-term success and adaptability in an ever-evolving market landscape.

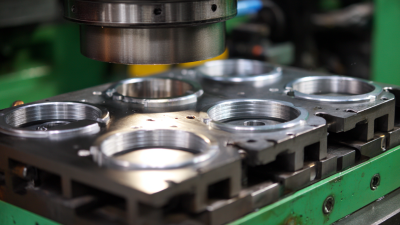

Evaluating cost, quality, and supply chain efficiency is paramount when selecting a manufacturer for any business. Cost considerations go beyond just the initial price tag; they also encompass potential long-term savings through efficient processes and reduced waste. Companies must analyze the complete cost structure, including logistics and operational expenses, to ensure that they are making a financially sound decision. A manufacturer that provides a competitive price without compromising on quality can significantly influence a business's profitability.

In addition to cost, the quality of the products being manufactured is critical to maintaining customer satisfaction and brand reputation. Implementing strict quality control measures and ensuring that manufacturers adhere to the industry's best practices can save businesses from costly recalls and loss of trust. Furthermore, with rising global competition, understanding supply chain efficiency is vital. This involves assessing a manufacturer’s ability to deliver on time, manage inventory effectively, and respond quickly to market changes. A robust supply chain not only minimizes lead times but also enhances a business's agility in adapting to fluctuations in demand or supply, ultimately ensuring long-term success.