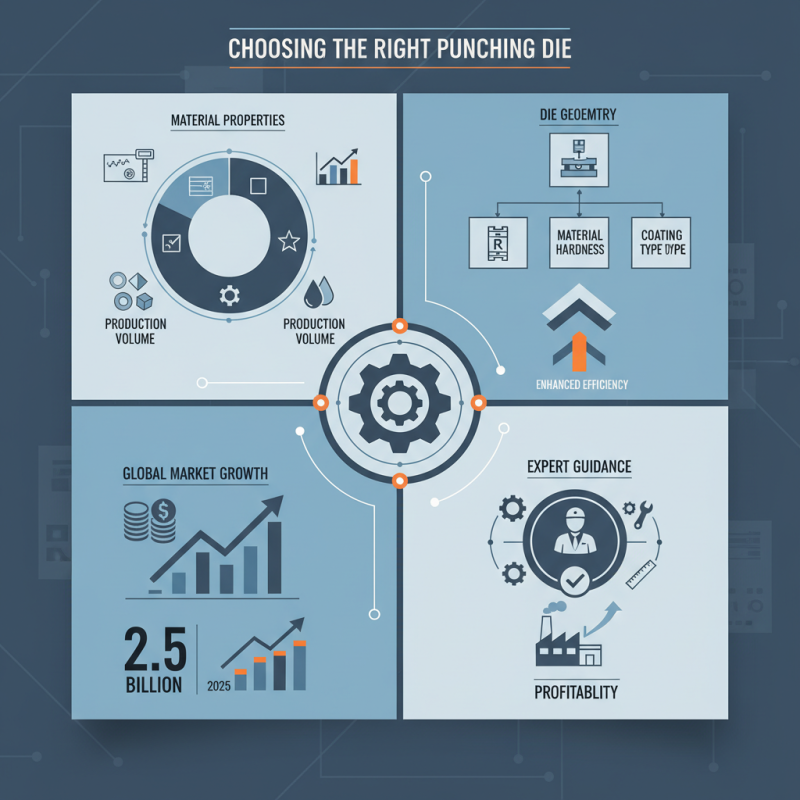

Choosing the right punching die is essential for maximizing efficiency and precision in metalworking applications. According to a recent industry report by the Metal Forming Association, the global punching die market is projected to reach $2.5 billion by 2025, driven by advancements in manufacturing technologies and increased demand for customized components. This underscores the necessity for manufacturers to invest in high-quality punching dies that can enhance production capabilities and reduce waste.

Dr. Henry Lin, a leading expert in metal forming processes, emphasizes the importance of selecting suitable punching dies by stating, "The effectiveness of a metalworking operation greatly depends on the compatibility of the punching die with the specific material and application requirements." His insights highlight that understanding the material properties, desired shape, and production volume is crucial for making an informed decision. With various factors to consider, from die geometry to material hardness, choosing the right punching die can significantly impact the overall success of metalworking projects. By following best practices and leveraging expert guidance, manufacturers can achieve optimal results and ensure long-term profitability.

Punching dies are an essential tool in the metalworking industry, used for creating precise shapes and cuts in various materials. Understanding the basics of punching dies involves grasping their design and function, which is crucial for selecting the right type for specific manufacturing needs. According to the Metal Fabrication 2022 Market Report, the global punching die market is projected to reach $5 billion by 2025, indicating a growing demand for efficient and effective metalworking processes. This growth is primarily driven by advancements in manufacturing technologies and increased demand across sectors such as automotive, aerospace, and electronics.

The selection of a punching die depends on several factors, including material type, desired thickness, and the complexity of the shapes being created. For instance, high-speed steel dies are commonly used for non-ferrous metals due to their durability and resistance to wear. The report further highlights that around 60% of manufacturers are now focusing on investing in personalized die solutions, which allow for greater flexibility and precision in production. Additionally, understanding the different types of punches and their respective applications—such as single-stroke versus multiple-stroke punches—can significantly enhance operational efficiency and reduce material wastage. By familiarizing themselves with these fundamental concepts, metalworkers can make informed decisions when selecting punching dies to meet their production requirements.

This chart represents the relative importance rating of various factors to consider when choosing a punching die for metalworking. Each factor is rated on a scale of 1 to 10, indicating its significance in the decision-making process.

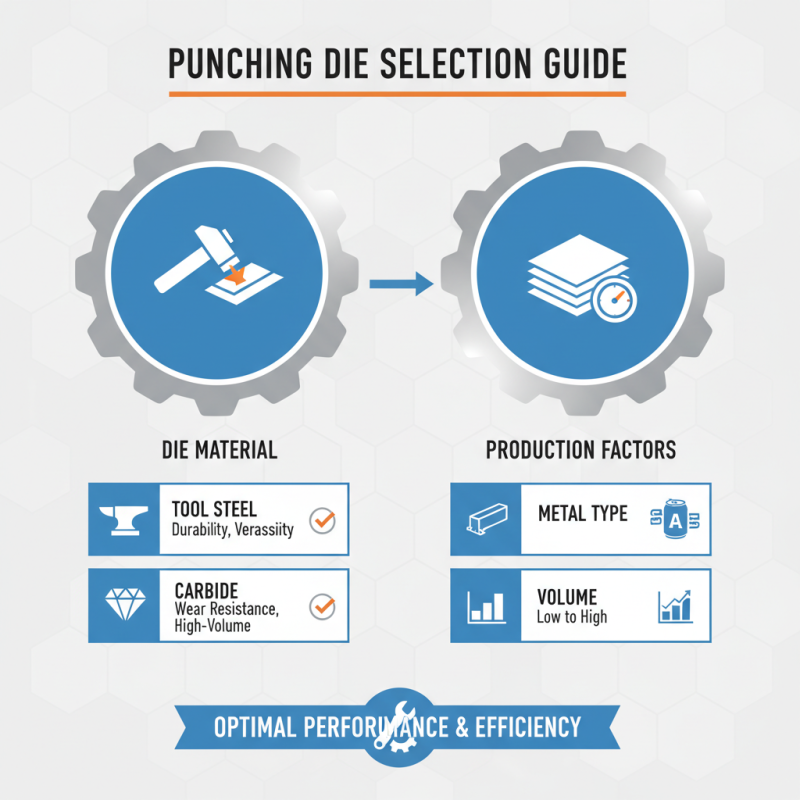

When selecting a punching die for your metalworking needs, several critical factors need to be taken into account to ensure optimal performance and efficiency. Firstly, the material of the die itself is paramount. Common materials include tool steel and carbide, each offering different advantages in terms of durability and wear resistance. The choice of material will largely depend on the type of metal being punched as well as the expected production volume—high-volume production may warrant a more robust die to withstand repeated use.

Another essential consideration is the die geometry, which includes the shape and size of the punch and die assembly. An accurately designed geometry ensures proper alignment and clearance, minimizing the risk of defects in the punched materials. Additionally, factors like the required hole size and shape, as well as the thickness of the material to be punched, should influence your decision. Moreover, the compatibility of the die with existing machinery plays a crucial role; ensuring it fits the press and aligns with your production processes will streamline operations and improve productivity.

When selecting a punching die for metalworking, understanding the various types and their specific applications is crucial. The most common types of punching dies include straight punches, compound punches, and progressive dies. Straight punches are ideal for simple hole-making tasks in sheets and plates, where precision is paramount. They deliver excellent results when used for operations that require a single action, ensuring clean and accurately positioned holes.

On the other hand, compound punches are designed for more complex applications, incorporating multiple operations within a single stroke. This type of die can cut, bend, and shape metal, making it suitable for creating intricate components in a single pass. Progressive dies take this a step further by allowing continuous production, where the workpiece moves through multiple stations of the die to achieve various operations sequentially.

This is particularly useful in high-volume production settings where efficiency and speed are key factors. Understanding these options will help professionals choose the right punching die to meet their specific metalworking requirements.

When selecting the right punching die for your metalworking needs, evaluating material compatibility is crucial. The die's ability to withstand the specific characteristics of the workpiece material dictates its performance and longevity. Different metals, such as aluminum, steel, and brass, come with distinct properties, including hardness, ductility, and wear resistance. A die made from a material that doesn't complement the workpiece can lead to premature wear, deformation, or failure during operation, ultimately resulting in costly downtime.

In addition to physical properties, consider the thickness and type of material being used. Thicker materials may require more robust dies designed for high-stress applications, while thinner materials might necessitate precision dies for cleaner cuts. Understanding the interaction between the punching die material and the workpiece can inform decisions about coatings or treatments that can enhance performance, such as improving resistance to wear or friction. Balancing these factors will ensure you choose a punching die that meets the demands of your specific metalworking projects while optimizing productivity.

Maintaining your punching die is crucial for ensuring its longevity and optimal performance in metalworking applications. Regular cleaning is one of the most effective maintenance practices. After each use, it's important to remove metal shavings and debris that may accumulate on the die surfaces. This not only prevents wear but also improves the quality of the punched materials. Using appropriate cleaning solutions and soft brushes can help preserve the integrity of the die without causing any damage.

Another essential tip is to check for any signs of wear or damage regularly. Inspect the punching die for nicks, chips, or cracks, as these can significantly affect its performance and lead to increased downtime. If wear is detected, consider re-sharpening or replacing the die before it causes further issues. Additionally, proper storage is vital; keep the dies in a dry, humidity-controlled environment to prevent rust and corrosion. By implementing these maintenance tips, metalworkers can extend the life of their punching dies and ensure consistent, high-quality results in their projects.

| Punching Die Type | Material Compatibility | Thickness Range (mm) | Maintenance Frequency | Lifespan (cycles) | Common Applications |

|---|---|---|---|---|---|

| Standard Punching Die | Steel, Aluminum | 0.5 - 10 | Every 1000 cycles | 50,000 | General Fabrication |

| Heavy-Duty Punching Die | High Carbon Steel, Stainless Steel | 2 - 20 | Every 1500 cycles | 75,000 | Heavy Machinery Parts |

| Precision Punching Die | Brass, Copper | 0.2 - 5 | Every 500 cycles | 30,000 | Electronics Enclosures |

| Custom Punching Die | Various Metals | Custom Range | N/A | Varies | Specialized Applications |