In today's fast-paced manufacturing landscape, the need for increased production efficiency has never been more critical. One technology that stands at the forefront of this transformation is CNC machining. This advanced technique offers unparalleled precision and speed, enabling manufacturers to enhance their production capabilities by an impressive 30 percent or more. As industries strive to meet growing consumer demands while maintaining quality and reducing costs, CNC machining emerges as a game-changing solution.

In this ultimate guide, we will delve into the seven compelling reasons why CNC machining is revolutionizing production processes, examining how it not only streamlines operations but also bolsters overall productivity. Whether you're a seasoned professional in the manufacturing sector or exploring innovative solutions for your business, understanding the benefits of CNC machining is essential for staying ahead in today's competitive market.

CNC machining stands out as a revolutionary technology in the manufacturing sector, significantly enhancing production speed and efficiency. One of the foremost benefits of CNC machining is its ability to minimize human error through precise automation, leading to consistently high-quality products. This precision not only reduces waste but also accelerates the production timeline, making it an ideal choice for industries that require rapid turnaround without compromising on quality.

CNC machining stands out as a revolutionary technology in the manufacturing sector, significantly enhancing production speed and efficiency. One of the foremost benefits of CNC machining is its ability to minimize human error through precise automation, leading to consistently high-quality products. This precision not only reduces waste but also accelerates the production timeline, making it an ideal choice for industries that require rapid turnaround without compromising on quality.

When adopting CNC machining, consider implementing regular maintenance checks on your machines. This helps in identifying potential issues before they escalate, ensuring continuous productivity. Additionally, training your staff on CNC programming and operations can further enhance efficiency. Knowledgeable operators can better utilize machine capabilities, leading to faster setup times and smoother production processes.

Another vital tip is to utilize advanced software for design and simulation. These tools can streamline the design phase, allowing for quicker modifications and improved project turnaround. By harnessing the full potential of CNC machining, manufacturers can achieve not only speed but also a level of efficiency that drives growth and profitability.

CNC technology has revolutionized production processes, significantly enhancing efficiency and throughput. One of the key features driving this improvement is the high-precision capabilities of CNC machines. These machines utilize advanced algorithms and automated software that streamline operations, thereby minimizing errors and reducing the time taken for setup and adjustments. With multi-axis machining centers, manufacturers can perform complex tasks in a single setup, leading to increased production rates and reduced lead times.

Moreover, the integration of artificial intelligence into CNC machining continues to transform the landscape of manufacturing. AI algorithms optimize machining processes by predicting tool wear and adjusting parameters in real time, which maintains consistent quality while boosting productivity. The growing trend of automation further accelerates these enhancements, as CNC machines require less manual intervention and can operate continuously, maximizing output and efficiency. As the global CNC machine tools market expands, driven by these technological advancements, businesses that adopt these innovations can expect substantial gains in production efficacy.

CNC machining has emerged as a formidable alternative to traditional manufacturing methods, significantly enhancing production efficiency. This advanced technique excels in creating complex parts with high precision and speed, leading to a remarkable increase in production rates—up to 30% faster compared to conventional processes. The key advantage lies in its subtractive nature, allowing for rapid material removal and intricate geometries without the extensive setup times typically associated with traditional manufacturing.

In contrast, traditional methods often rely on manual tools and labor-intensive processes, which can lead to inconsistencies and slower output rates. CNC machining seamlessly integrates computer numerical control to minimize human error and optimize production timelines. This technology not only streamlines operations but also accommodates the growing demand for customized and high-quality components across various industries. As companies look to remain competitive in fast-paced markets, the shift towards CNC machining reflects a strategic move to harness its efficiency, precision, and adaptability—all vital for modern manufacturing excellence.

CNC machining is at the forefront of modern manufacturing, showcasing its ability to minimize waste and maximize productivity. According to a report by the American Society of Mechanical Engineers, CNC machines can reduce material waste by as much as 30% compared to traditional machining methods. This significant reduction in waste not only lowers production costs but also benefits the environment, aligning with the broader industry trend towards sustainability. By precisely cutting materials to exact specifications, CNC technology ensures that every piece produced utilizes the maximum amount of raw material.

Moreover, the increase in production efficiency is evidenced by a study from the National Institute of Standards and Technology, which found that implementing CNC machinery can lead to productivity gains of up to 40%. This is largely due to the automation and consistency that CNC provides, allowing for faster cycle times and less human intervention. With capabilities such as 3D modeling and computer-aided design, CNC machines streamline workflows while maintaining high precision, ultimately enhancing overall output without compromising quality. As industries strive to meet growing demand, CNC machining continues to be a driving force in achieving operational excellence.

CNC machining has been at the forefront of innovation in production efficiency, particularly as industries increasingly turn to advanced manufacturing technologies. Real-world case studies illustrate that companies adopting CNC solutions can push production speeds to new heights. For instance, enterprises that integrate CNC machining have reported up to a 30% reduction in production time due to enhanced precision and reduced waste. This aligns with findings from recent studies highlighting that integrating artificial intelligence in manufacturing processes can lead to significant operational improvements, optimizing everything from supply chains to energy consumption.

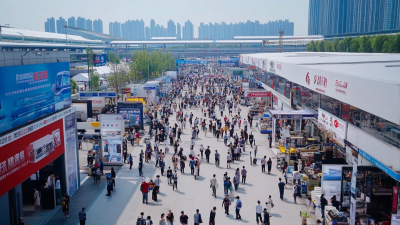

Additionally, innovative approaches, such as multi-robot task allocation within smart production systems, are becoming critical in achieving efficiency in Industry 4.0 settings. Research shows that these methodologies improve production scheduling and labor utilization, enabling manufacturers to respond rapidly to market demands. With countries like China emerging as leaders in advanced manufacturing capabilities, the application of CNC technology and AI is not just a competitive advantage, but a necessity for staying relevant in a rapidly evolving industrial landscape. These transformative solutions empower manufacturers to enhance productivity, cut costs, and ultimately drive greater profitability.