CNC processing is a vital technology in modern manufacturing. It stands for Computer Numerical Control. This method automates processes, leading to enhanced precision and efficiency. According to a report from the International Federation of Robotics, CNC machines have become integral in numerous industries, with a global market projected to grow significantly. The benefits are evident: reduced human error, faster production times, and complex design capabilities.

However, CNC processing also presents challenges. The initial investment can be substantial, and skilled operators are required. Many businesses struggle with workforce training. A report from Deloitte highlights that talent gaps in advanced manufacturing could hinder growth. Furthermore, while automation improves consistency, it may reduce the need for low-skilled labor, raising concerns about job displacement.

Ultimately, understanding the nuances of CNC processing is essential. Engineers and manufacturers must weigh the benefits against potential drawbacks. Each application demands careful consideration of resources and goals. Embracing this technology requires ongoing reflection and adaptation to ensure long-term success in an evolving landscape.

CNC processing, or Computer Numerical Control processing, is a revolutionary technology. It uses computers to control machine tools. This method enhances precision and can produce complex designs. Imagine a machine automatically carving details into metal. This is the magic of CNC.

The definition is straightforward: CNC processing translates digital designs into physical products. Users create a blueprint on software. The machine then follows these digital instructions. It cuts, drills, or mills materials. Users often note the speed and accuracy.

However, CNC processing has its challenges. Initial setup can be time-consuming. Not all designs translate perfectly. Sometimes, adjustments are necessary. Users must be ready to troubleshoot. This dynamic interplay between technology and user creativity creates a unique production experience.

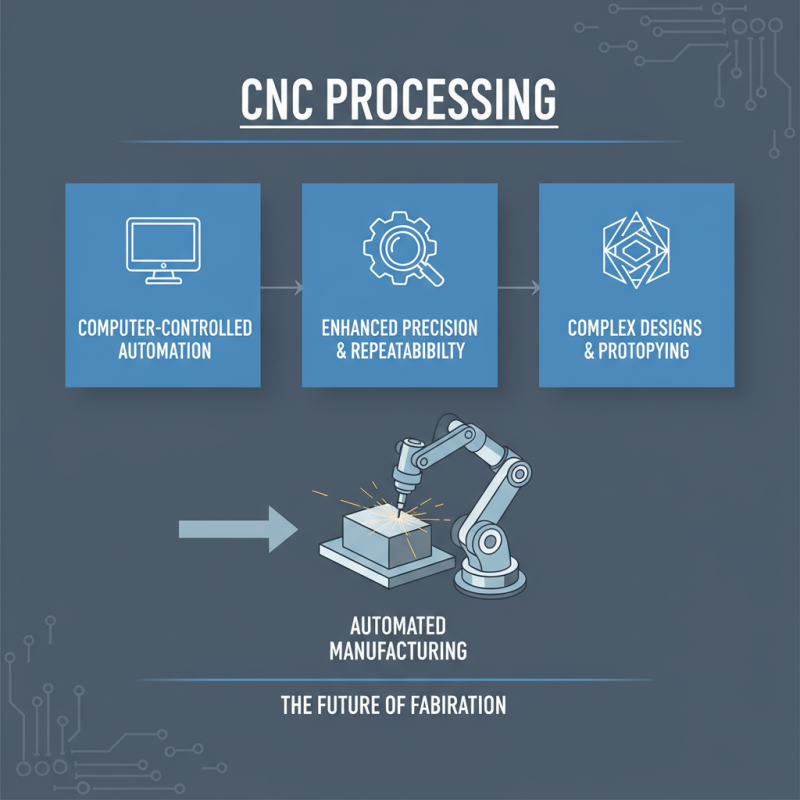

CNC processing offers several key benefits for manufacturing industries. One major advantage is its precision. Machines can operate with minimal human error. This leads to high repeatability in production. Consistent quality is essential for creating reliable products.

Another important benefit is efficiency. CNC machines can run continuously, reducing downtime. They can produce complex shapes with less manual intervention. This not only saves time but can also lower labor costs. However, initial setup and programming require skilled workers, which can be a challenge.

Flexibility is another aspect worth noting. CNC processing allows for quick adjustments in designs. This means manufacturers can respond fast to market changes. Yet, relying solely on this technology may lead to overconfidence. Balancing automation with human oversight is vital for long-term success in the industry.

| Benefits | Applications |

|---|---|

| High Precision | Aerospace Components |

| Reduced Waste | Medical Devices |

| Increased Efficiency | Automotive Parts |

| Flexibility in Production | Consumer Electronics |

| Automation Capability | Machinery and Equipment |

CNC processing is revolutionizing various sectors. It offers

precision and efficiency that manual methods struggle to match. In the automotive industry,

CNC machining creates intricate parts like engine components. This leads to improved performance and reliability.

However, ensuring tolerance is critical; slight errors can cause major issues.

In aerospace, CNC processing plays a crucial role. It fabricates lightweight

yet durable components for aircraft. Attention to detail is essential here. A flawed part can jeopardize safety.

Medical devices also benefit significantly. CNC precision allows for customized implants and surgical instruments.

Yet, quality control must be rigorous to ensure patient safety.

Despite its advantages, not all CNC projects go smoothly. Sometimes, unexpected challenges arise. Material selection

and machinery capabilities can influence outcomes. Each sector has its standards and requirements. Mistakes can be costly. Learning from these instances is vital for improvement and innovation.

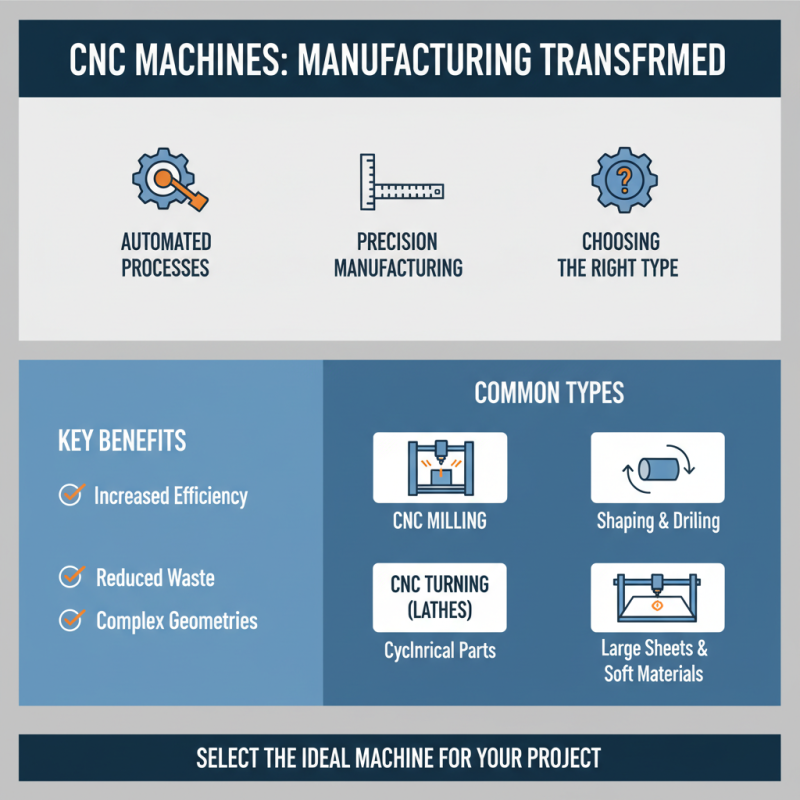

CNC machines have transformed manufacturing. They automate processes with precision. Understanding their types helps in choosing the right one for a project.

There are several types of CNC machines. The most common include milling machines, lathes, and routers. Each type serves specific functions. For example, milling machines cut and shape materials, while lathes are more focused on rotating products. Routers are great for detailed designs in wood or plastic. These distinctions can significantly affect the outcome of a project.

However, using CNC machines isn't always straightforward. Operators must have training to program and maintain these machines. Errors can lead to wasted material and time. It's crucial to consider your project's needs carefully. Making the wrong choice in machine type can result in unsatisfactory results. Understanding the functions of different CNC machines can minimize these pitfalls.

CNC processing is evolving rapidly, with future trends focusing on automation and sustainability. Industry reports indicate that the global CNC market is projected to reach $95 billion by 2026, driven by advancements in technology. This growth emphasizes the need for manufacturers to adopt smart processing to remain competitive.

One innovative trend is the integration of artificial intelligence in CNC machines. AI can enhance precision and reduce errors. Data shows that companies using AI in their CNC operations report a 30% increase in productivity. However, transitioning to AI involves challenges, such as initial investment costs and the need for skilled workers.

Tip: Consider investing in training for your staff to better adapt to new technologies.

Furthermore, the use of sustainable materials in CNC processing is gaining traction. Companies are prioritizing eco-friendly solutions to meet customer demands. Research indicates that over 70% of consumers prefer products made with sustainable practices. However, sourcing these materials can sometimes be difficult.

Tip: Regularly assess your supply chain for sustainable options.

Staying ahead in CNC processing requires embracing these innovations while analyzing their impacts carefully. Balancing technological advancements with practical challenges is key.