In today's fast-paced manufacturing environment, the efficiency of CNC machining processes is paramount for maintaining competitiveness. According to a recent report by the Association for Manufacturing Technology (AMT), companies that effectively optimize their CNC service operations can increase productivity by up to 20%. This statistic underscores the importance of implementing best practices in CNC service to enhance machining efficiency and reduce downtime.

Industry expert Dr. Emily Chen, a leading figure in precision machining, emphasizes, "Maximizing CNC service capabilities is not just about maintaining machines; it's about creating a holistic approach that integrates technology and workforce training." This perspective is crucial as businesses strive to leverage CNC technology to its fullest potential. The implementation of essential CNC service tips can lead to significant improvements in operational output, ultimately driving higher profitability.

As we delve into the ten essential CNC service tips for maximizing your machining efficiency, it becomes evident that each recommendation is rooted in a strategy that aligns technology with efficiency goals. By focusing on proactive maintenance, workforce skill enhancement, and systematic upgrades, manufacturers can achieve a streamlined operation that meets the demands of a rapidly evolving market.

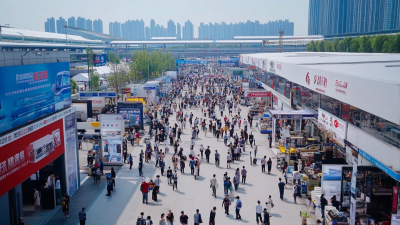

The adoption of automation in metal forming processes is increasingly influencing machining efficiency, driven by a surge in market demand. According to industry reports, over 70% of manufacturers are now implementing automated solutions to improve production capabilities. This shift is not only about keeping pace with competition but also about enhancing operational precision and reducing machine downtime. Automated CNC systems optimize workflows, allowing for real-time adjustments that streamline production processes, ultimately leading to shorter lead times and reduced costs.

Moreover, advancements in robotics technology further support this transformation. A recent study highlighted that integrating robotics into CNC operations can enhance productivity by up to 30%, providing manufacturers with a significant edge. By automating repetitive and labor-intensive tasks, CNC machines can operate at higher speeds and maintain consistent quality, thereby maximizing output. As the industry evolves, utilizing these innovative techniques becomes essential for companies looking to stay ahead and meet the growing demands of the marketplace.

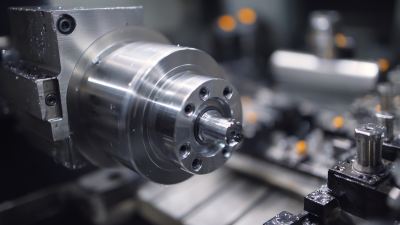

Understanding feed rates is crucial for achieving optimal machining performance in CNC operations. The feed rate, defined as the speed at which the cutting tool moves through the material, directly affects cutting efficiency, surface finish, and tool life. Selecting the right feed rate not only ensures that the machining process runs smoothly but also helps prevent tool wear and overheating, which can lead to costly downtime and rework.

To maximize machining efficiency, operators should take into account several factors when determining the appropriate feed rate. These factors include the type of material being machined, the geometry of the cutting tool, and the specific machining operation being performed. For instance, harder materials may require a slower feed rate to achieve a clean cut without damaging the tool. In contrast, softer materials can typically be machined at higher feed rates. Additionally, utilizing manufacturer guidelines and conducting trial runs can help fine-tune feed rates for different setups, ensuring that the CNC machine operates at its peak performance while maintaining high-quality output.

Choosing the right tooling is paramount for optimizing machining efficiency in CNC operations. Studies indicate that selecting precision tools can lower production times by up to 30%. This significant reduction not only enhances workflow but also leads to higher output and improved competitiveness in the market. Utilizing advanced tool materials and geometries tailored for specific applications can yield better cutting speeds and longer tool life, minimizing downtime and direct costs.

Tips for maximizing machining efficiency include investing in high-quality tooling and regularly assessing tool performance. One essential piece of advice is to implement a preventative maintenance schedule for your CNC machines, which can help identify potential issues before they lead to costly failures. Additionally, employing AI-driven operations management systems can streamline processes and reduce unnecessary tasks, potentially cutting workforce management time by 50%. By continuously analyzing production data, manufacturers can make informed decisions about tooling needs and inventory management, ultimately paving the way for enhanced productivity and reduced production cycles.

| Tip | Description | Impact on Efficiency |

|---|---|---|

| Regular Maintenance | Implement routine equipment maintenance to prevent breakdowns. | Reduces downtime by up to 20% |

| Tool Selection | Choose the right tools suited for the specific machining task. | Can reduce production time by 30% |

| Calibrate Machines | Regular calibration ensures precision in machining operations. | Enhances accuracy, improving product quality. |

| Material Choice | Select materials that are easier to machine to save time. | Reduces tool wear, extending tool life. |

| Process Optimization | Evaluate and adjust machining parameters for efficiency. | Improves cycle times significantly. |

| Train Operators | Provide comprehensive training for machine operators. | Enhances operational efficiency and safety. |

| Inventory Management | Maintain optimal inventory levels to keep production flowing. | Minimizes delays caused by material shortages. |

| Use Technology | Incorporate software for design and programming. | Improves design precision and reduces programming time. |

| Feedback Loop | Establish a feedback system for continuous improvement. | Promotes a culture of efficiency and responsiveness. |

Preventative maintenance is crucial for maximizing the longevity and efficiency of CNC machines. By implementing strategic maintenance practices, manufacturers can enhance their machining capabilities by up to 40%. This becomes increasingly important in today’s landscape where manufacturers face high uncertainty and low growth, prompting a need to extract maximum value from every asset. Regular servicing not just extends machine life but also ensures that operations run smoothly, minimizing downtime and boosting productivity.

To optimize CNC service, consider these essential tips:

The integration of real-time monitoring and data analytics is pivotal in enhancing the efficiency of manufacturing processes. As industries increasingly embrace advanced technologies, the focus on predictive maintenance has garnered substantial attention. This approach utilizes the Internet of Things (IoT) and artificial intelligence (AI) to foresee equipment failures, thereby minimizing unexpected downtimes and extending asset lifespans. With forecasts indicating a significant surge in the predictive maintenance market, reaching over $215 billion by 2032, manufacturers are recognizing the long-term benefits of investing in data analytics capabilities.

Furthermore, the digitization of manufacturing is set to reshape the industry landscape, with projections estimating the market size to grow from $357.58 billion in 2023 to approximately $326.98 billion by 2032. This transformation emphasizes the importance of intelligent solutions that not only streamline production processes but also optimize resource allocation. As businesses implement sophisticated monitoring systems, the potential for enhanced productivity and reduced operational costs becomes evident, paving the way for a more resilient and competitive manufacturing sector.