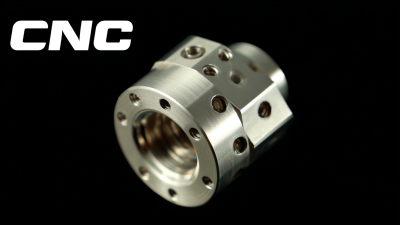

In the rapidly evolving landscape of CNC manufacturing, sourcing high-quality parts for CNC operations is paramount to maintaining competitive edge and operational efficiency. Industry reports indicate that nearly 40% of manufacturers experience delays and increased costs due to poor-quality parts, underscoring the necessity for robust sourcing strategies.

According to a recent study by the Association for Manufacturing Technology, 75% of businesses in the CNC sector see a direct correlation between part quality and production efficiency, highlighting its critical role in the manufacturing process. As the demand for precision engineering continues to rise, navigating the complexities of supplier relationships and material specifications becomes essential for professionals aiming to enhance their production capabilities.

This blog will explore five essential tips for sourcing quality parts for CNC, providing insights to help manufacturers optimize their supply chains and ultimately achieve superior outcomes.

Understanding your CNC manufacturing requirements is crucial for effective sourcing of quality parts. According to a report by the Manufacturing Institute, approximately 79% of manufacturers experience challenges related to sourcing materials and components, underscoring the necessity of a clear understanding of specifications and operational needs. This includes knowing the types of materials that will work best for your projects, whether it’s aluminum, stainless steel, or composite materials, as each has unique properties that can significantly impact the final product.

Moreover, aligning your sourcing strategy with industry standards is essential. The International Organization for Standardization (ISO) reports that companies adhering to quality management standards often see a 20% reduction in supply chain costs. By identifying your quality benchmarks and integrating them into your sourcing process, you can work with suppliers who meet these criteria, ultimately minimizing defects and enhancing operational efficiency. Leveraging advanced technologies, such as CAD software, can also help in precisely defining requirements, ensuring that sourced parts fit seamlessly into your CNC operations.

When sourcing quality parts for CNC manufacturing, identifying reliable suppliers is crucial to ensuring the success of your projects. One of the key qualities to look for in a supplier is their reputation within the industry. A well-established supplier with positive reviews from previous clients is more likely to deliver quality parts consistently. Checking online reviews, testimonials, and seeking referrals from industry peers can help gauge a supplier's reliability.

Another essential quality is the supplier’s ability to provide comprehensive product support. This includes technical assistance, product specifications, and customization options. Suppliers that are willing to invest time in understanding your specific needs and can offer solutions tailored to your requirements demonstrate a commitment to quality and customer service. Additionally, consider their production capabilities and quality control processes; a supplier that adheres to strict quality assurance practices is more likely to offer parts that meet your specifications and standards. By focusing on these key qualities, businesses can forge partnerships that enhance their CNC manufacturing efforts.

When sourcing quality parts for CNC (Computer Numerical Control) manufacturing, evaluating material quality and specifications is paramount. The first step is to understand the specific requirements of your project, which includes analyzing the intended use of the parts, the operating environment, and the mechanical properties needed for optimum performance. Different materials have distinct characteristics; for example, aluminum is lightweight and has excellent machinability, while steel offers high strength and durability. Ensuring that the selected material aligns with the project’s demands is crucial for the longevity and functionality of the final product.

Next, consider the specifications provided by the suppliers. Always request detailed reports, including material certifications, mechanical property data, and traceability information. This documentation can help verify that the materials meet industry standards and comply with regulations. Additionally, paying attention to the supplier's quality control processes can provide insights into their reliability. By maintaining open communication with suppliers, you can clarify any ambiguities and ensure that the components produced not only meet but exceed the expectations outlined in your project specifications.

Establishing strong communication channels with suppliers is crucial in sourcing quality parts for CNC manufacturing. According to a report by the Institute for Supply Management, effective communication can reduce lead times by up to 30%, significantly enhancing the overall efficiency of the manufacturing process. Building strong relationships enables clearer expectations and fosters trust, which is essential for maintaining quality control throughout the supply chain.

Tip 1: Define Clear Specifications – When communicating with suppliers, ensure that you provide comprehensive part specifications, including material types, tolerances, and finish requirements. This clarity can help prevent misunderstandings and reduce the chances of receiving subpar parts.

Tip 2: Utilize Technology – Implementing communication tools like cloud-based platforms can streamline information sharing. A study from McKinsey highlights that utilizing digital communication channels can improve project efficiency by as much as 25%. Regular video conferences or instant messaging can help keep everyone aligned, especially when dealing with complex projects.

By focusing on effective communication, manufacturers can not only enhance the quality of sourced parts but also create a robust supply chain that adapts to changing market demands.

In today's rapidly evolving CNC manufacturing landscape, leveraging technology for efficient sourcing and tracking of parts is not just an option; it's a necessity. A recent report by NexIDs indicates that 40% of manufacturing companies that integrated advanced sourcing technologies saw a reduction in procurement costs by up to 25%. By using cloud-based platforms and AI-driven analytics, businesses can streamline their sourcing processes, reduce lead times, and ensure they are obtaining high-quality parts from reliable suppliers.

Moreover, implementing IoT devices can significantly enhance tracking capabilities throughout the manufacturing process. According to a study published by Global Data, 52% of manufacturers that adopted IoT technology experienced improved visibility of their supply chains, allowing for real-time data analysis and decision-making. This level of insight not only mitigates risks associated with part quality but also enables manufacturers to respond swiftly to changes in demand or supply disruptions. As the industry continues to progress, those who embrace these technological advancements will set themselves apart in the quest for quality and efficiency in CNC manufacturing.

| Tip | Description | Technology Used | Benefits |

|---|---|---|---|

| Research Suppliers | Conduct thorough research on potential suppliers to ensure their credibility. | Online Supplier Platforms | Increased confidence in supplier selection. |

| Quality Assurance | Implement rigorous quality control measures and standards. | Quality Management Software | Reduction of defects and improved product quality. |

| Use CAD Software | Utilize CAD tools for precise specifications and part designs. | Computer-Aided Design (CAD) | Accurate part manufacturing and better design communication. |

| Track Inventory | Adopt inventory management systems to track available parts. | Inventory Management Software | Prevention of stockouts and overstock situations. |

| Leverage Data Analytics | Use data analytics to evaluate supplier performance continuously. | Data Analysis Tools | Informed decision making and improved sourcing strategies. |