In the realm of manufacturing, the significance of understanding industry production standards cannot be overstated, particularly when it comes to die mold components. These critical elements serve as the foundation for precision engineering, impacting everything from product quality to production efficiency. As global demand for high-quality products increases, the role of factories, especially those in China, becomes paramount in delivering excellence. By adhering to stringent production standards, these facilities not only ensure optimized die mold components but also contribute to the broader landscape of manufacturing that meets international expectations.

This blog will explore the evolution of industry standards, the importance of quality control in die mold production, and how Chinese factories are leading the charge in creating superior components that cater to a worldwide market.

When comparing die mold component production standards, several key factors play a crucial role in ensuring optimal performance and longevity of the molds. The first factor to consider is material quality. High-grade materials not only enhance durability but also reduce wear and tear over time. Investing in superior materials can lead to more precision in the final products.

Tips: Always check suppliers for certifications and materials testing to ensure compliance with industry standards. Prioritize suppliers who can provide transparency in their material sourcing.

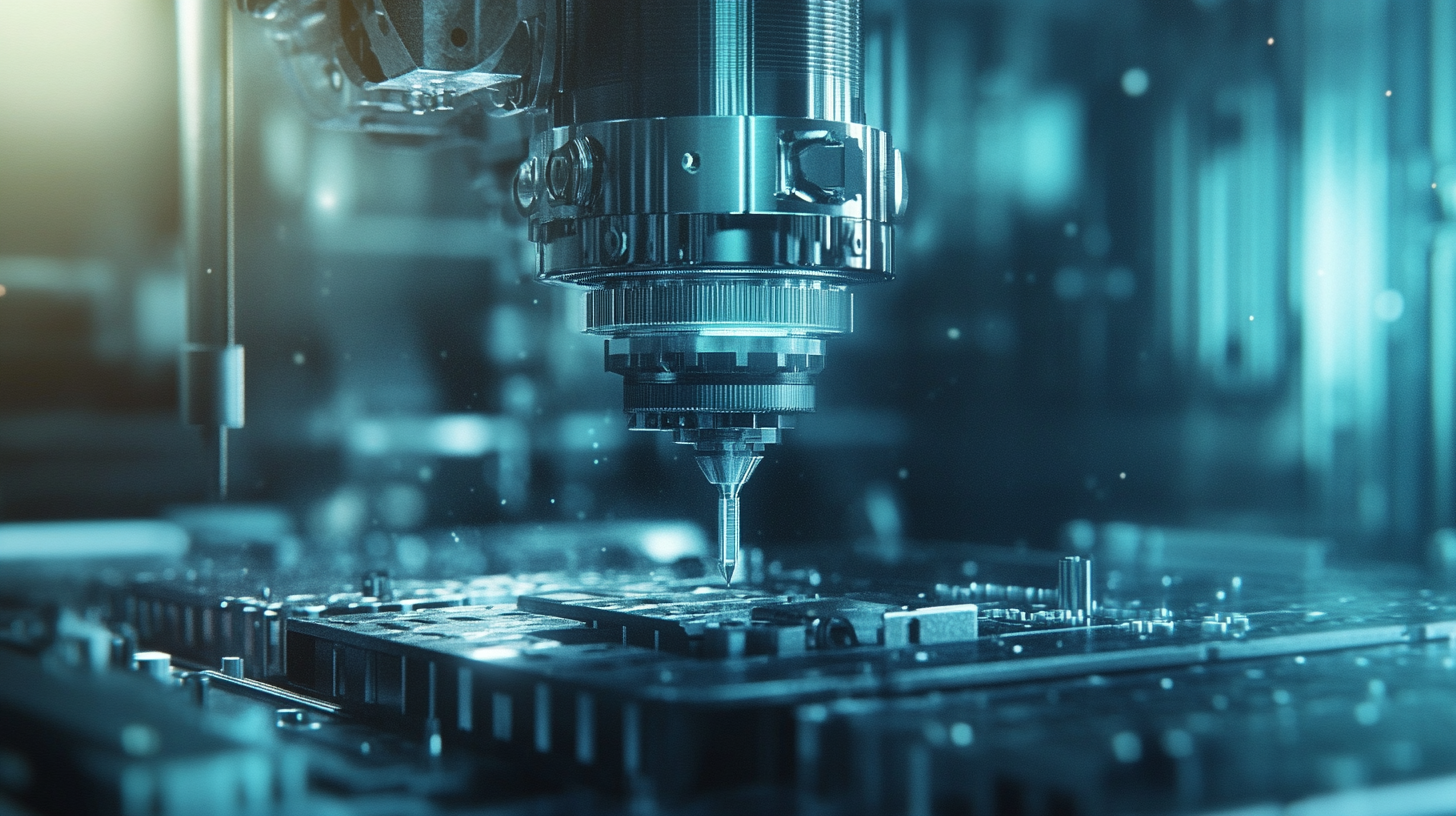

Another critical factor is the precision of manufacturing processes. Techniques such as CNC machining and EDM (Electrical Discharge Machining) should be scrutinized during the evaluation of production standards. Precision equipment ensures that mold components fit together flawlessly, ultimately improving production efficiency and reducing scrap rates.

Tips: Ask for detailed documentation of the manufacturing processes used, including any quality control measures that are in place to verify precision during production.

When it comes to die mold components, understanding industry-specific standards is crucial for ensuring efficiency and quality across various sectors. Different industries, such as automotive, aerospace, and consumer electronics, have unique requirements that dictate how molds are designed, manufactured, and maintained. For example, the automotive sector may prioritize durability and cost-effectiveness, while the aerospace industry may focus on precision and lightweight materials. This diversity necessitates a tailored approach to production standards in each field.

**Tip:** Always stay updated on the latest compliance regulations in your industry to avoid costly mistakes. Regular training for your team on these standards can help streamline your production processes.

In addition to industry standards, it’s essential to compare them to identify best practices that can be applied across sectors. For instance, while the specifications for tolerances may vary, the concepts of quality assurance and continuous improvement remain universal. Implementing a cross-industry benchmarking strategy can expose gaps in your current processes and inspire innovations that enhance your die mold components.

**Tip:** Consider establishing a collaborative network with peers in different industries to share insights on production standards and innovations. This can lead to creative solutions that push the boundaries of your manufacturing capabilities.

| Industry Sector | Production Standard | Material Specifications | Precision Tolerance | Testing Requirements |

|---|---|---|---|---|

| Automotive | ISO/TS 16949 | Steel, Aluminum | ±0.01 mm | Dimensional and Functional Tests |

| Aerospace | AS9100 | Titanium, Composites | ±0.005 mm | NDT, Material Certification |

| Medical Devices | ISO 13485 | Medical Grade Plastics | ±0.01 mm | Sterilization Validation |

| Electronics | IPC-A-600 | FR-4, Copper | ±0.05 mm | Electrical Testing, Visual Inspection |

| Consumer Goods | ISO 9001 | Polypropylene, ABS | ±0.02 mm | Functional Testing, Compliance Checks |

When evaluating mold components, understanding the quality and performance criteria is crucial for optimizing production results. According to a report from Market Research Future, the global mold component market is projected to grow at a CAGR of 6.5% from 2021 to 2027, driven by increasing demand from industries such as automotive and consumer goods. Factors such as material selection, surface finish, and dimensional accuracy play significant roles in determining the overall performance of die mold components. High precision in these areas not only enhances durability but also reduces the risk of defects during production runs.

Tip 1: Always select materials with proven performance records in specific applications. For example, steel alloys like P20 and S7 are favored for their hardness and resistance to wear, which are essential for producing high-quality mold components.

Additionally, maintaining stringent inspection protocols is essential. Utilizing advanced methods such as Coordinate Measuring Machines (CMM) can significantly improve the detection of deviations from specifications. A study by the Plastic Industry Association indicates that companies employing rigorous quality assurance practices have reduced production costs by up to 30%.

Tip 2: Incorporate regular training for your team on the latest inspection technologies to ensure consistent quality standards are met across all projects. High-quality molds lead to higher efficiency, reduced cycle times, and ultimately, better product quality.

Material selection is a critical component in the manufacturing of die mold standards, significantly influencing their performance, durability, and cost-effectiveness. The choice of materials directly affects the final product's ability to withstand high temperatures, mechanical stresses, and abrasive environments. For instance, using high-quality steel alloys can enhance the lifespan of die molds, providing resistance to deformation and wear. Additionally, innovative materials like high-performance polymers and composites are gaining popularity due to their lightweight nature and excellent thermal properties, which can result in more efficient production processes.

The impact of material selection extends beyond durability; it also plays a vital role in the precision and quality of molded parts. The right material can enhance the mold's thermal conductivity, leading to better temperature regulation during the molding process. This precision reduces defects and ensures a higher standard of output, aligning with industry production standards. Engineers and manufacturers must collaborate closely to evaluate both the physical properties of materials and their compatibility with the intended production techniques—ultimately driving the efficiency and reliability of die mold components in today’s competitive landscape.

This chart illustrates the impact of different materials on die mold standards across various production categories.

In the realm of die mold production, striking the right balance between cost and quality is paramount. Manufacturers often grapple with the challenge of maintaining high production standards while optimizing their budgets. Lowering costs can lead to compromised quality, affecting the longevity and performance of die mold components. Thus, understanding industry production standards becomes essential for any organization aiming to deliver reliable and efficient molds.

Recent trends in manufacturing have revealed the significance of investing in quality materials and innovative processes. For example, incorporating advanced technologies like 3D printing with fiber-reinforced composites can enhance precision while potentially reducing overall costs in the long run. By committing to quality upfront, manufacturers can minimize rework and waste, ultimately leading to greater profit margins and customer satisfaction. Therefore, finding this balance is not just a production strategy; it's a long-term business investment that shapes the future of die mold manufacturing.