In the rapidly evolving landscape of manufacturing, the demand for high-quality machining services continues to grow, driven by the need for precision and efficiency. According to a report by Research and Markets, the global machining services market is predicted to reach USD 210 billion by 2026, expanding at a CAGR of over 6% from 2021 to 2026. To stay competitive, companies must adopt advanced techniques and technologies to streamline operations and enhance productivity. Incorporating automated processes, advanced CNC machinery, and data analytics not only optimizes production cycles but also minimizes waste, ultimately leading to cost savings. As industries shift towards digital transformation, leveraging these innovations will be essential for organizations looking to maximize efficiency in their machining services, adapt to market fluctuations, and meet increasing customer expectations.

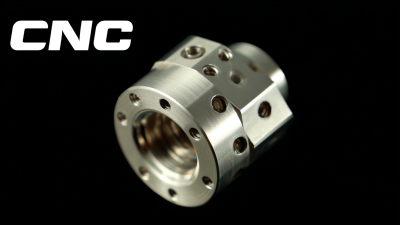

In the ever-evolving field of machining services, the adoption of advanced techniques is crucial for maximizing efficiency. One key method is the implementation of computer numerical control (CNC) technology. CNC machining allows for precise and consistent production, enabling manufacturers to maintain high standards while significantly reducing human error. By integrating CAD (Computer-Aided Design) with CNC, businesses can streamline their design processes, ensuring quicker turnaround times and improved accuracy.

Tips: To fully leverage CNC technology, invest in training your workforce to ensure they are well-versed in the programming and operation of CNC machines. Regular maintenance checks can also prevent downtime and keep machines running smoothly, further enhancing productivity.

Another advanced technique gaining traction is additive manufacturing or 3D printing. This technology enables the rapid production of complex geometries that traditional methods cannot achieve. By utilizing 3D printing in the prototyping phase, companies can save time and materials, allowing for quicker iterations and improvements based on real-world testing.

Tips: When incorporating additive manufacturing, focus on selecting the right materials and technologies suitable for your specific application. Collaborating with suppliers who have expertise in both additive and subtractive methods can also provide valuable insights and optimize production processes.

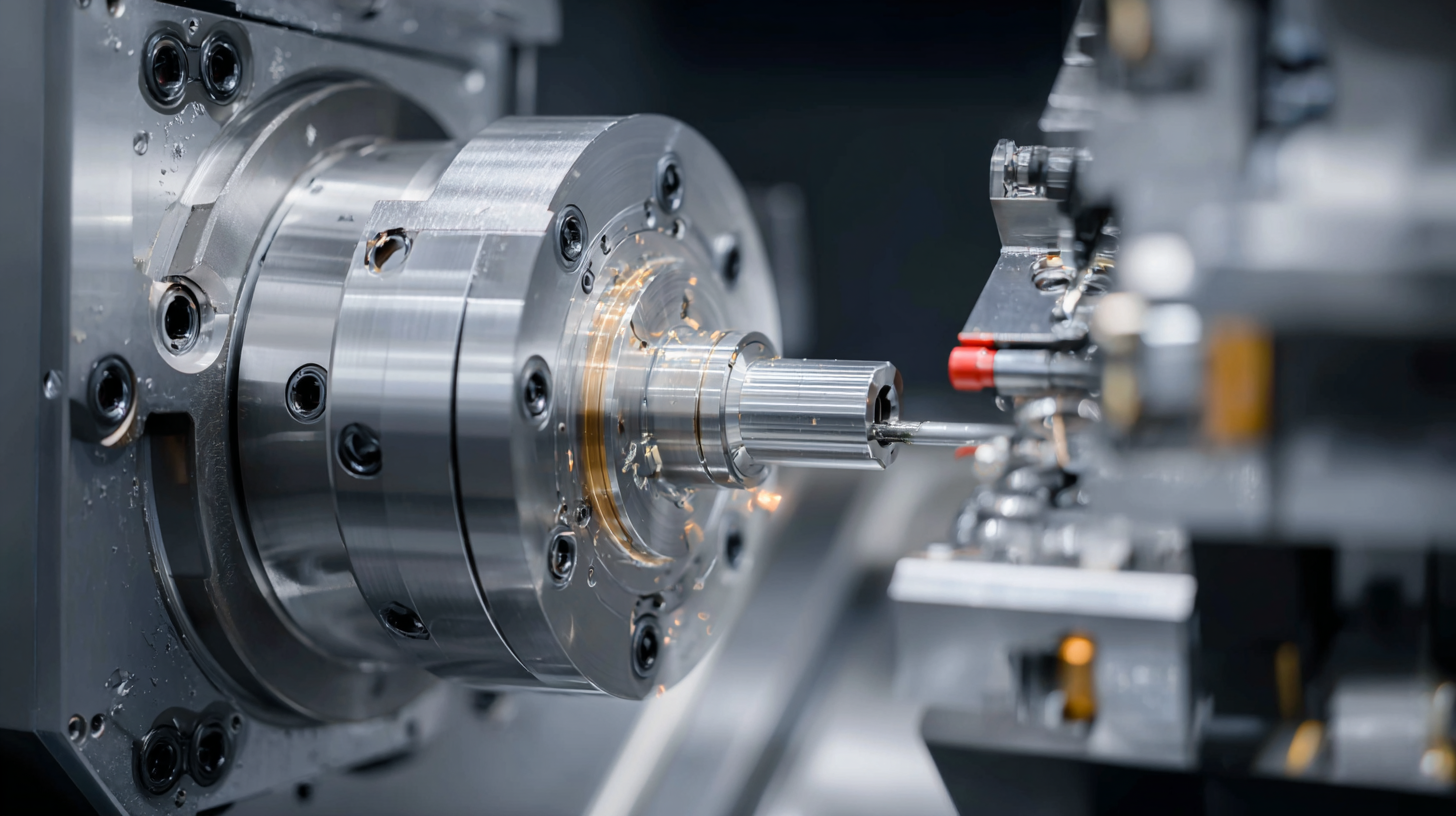

In the realm of machining services, the integration of

automation and

robotics has become a

game-changer for enhancing productivity. By leveraging these advanced

technologies, manufacturers can optimize their processes, reduce downtime,

and increase production rates. Automation streamlines repetitive tasks,

allowing skilled workers to focus on more complex operations that require

human oversight. Consequently, the overall efficiency of machining services

is significantly improved, leading to faster turnaround times and lower

operational costs.

Robotics, on the other hand, introduces a new level of

precision and

reliability. Robotic arms can perform

intricate machining tasks with unparalleled accuracy, minimizing errors and

enhancing product quality. Additionally, these machines can operate

continuously, which maximizes output and meets the demands of

high-volume production environments. By

embracing robotics in machining services, companies not only improve their

efficiency but also position themselves competitively in a fast-evolving

market, ready to adapt to future technological advancements.

Robotics, on the other hand, introduces a new level of

precision and

reliability. Robotic arms can perform

intricate machining tasks with unparalleled accuracy, minimizing errors and

enhancing product quality. Additionally, these machines can operate

continuously, which maximizes output and meets the demands of

high-volume production environments. By

embracing robotics in machining services, companies not only improve their

efficiency but also position themselves competitively in a fast-evolving

market, ready to adapt to future technological advancements.

The integration of Internet of Things (IoT) and data analytics technologies is transforming the landscape of machining services, enabling real-time monitoring that greatly enhances operational efficiency. The market for floating roof monitoring systems is projected to reach $135 million by 2024, with a remarkable compound annual growth rate (CAGR) of 9.7% from 2024 to 2031. This growth reflects the growing demand for advanced monitoring solutions in industries reliant on precise machining capabilities.

In parallel, the wireless industrial IoT sensor market is anticipated to grow from an estimated $7973.2 million in 2025 to $21498.2 million by 2033, highlighting a CAGR of 13.2%. This surge underscores the critical role of IoT sensors in facilitating the collection and analysis of data, allowing manufacturers to optimize processes, reduce downtime, and ultimately enhance productivity. As these technologies continue to evolve, they open new avenues for innovative applications in industrial automation and smart manufacturing, providing businesses with the tools necessary to stay competitive in an increasingly digital landscape.

This chart illustrates the efficiency levels of different machining service techniques. As advanced techniques, IoT integration, and data analytics are adopted, a significant increase in efficiency is observed compared to traditional methods.

Additive manufacturing has emerged as a revolutionary technology that significantly enhances design flexibility in machining services. It allows manufacturers to create complex geometries and intricate designs that are often challenging or impossible to achieve with traditional subtractive methods. By utilizing 3D printing techniques, companies can produce customized components tailored to specific requirements, thereby streamlining the design process and reducing lead times. This adaptability fosters innovation, enabling businesses to respond quickly to market demands and evolving customer needs.

Moreover, integrating additive manufacturing into machining services can optimize material usage and minimize waste. Traditional machining processes often lead to considerable scrap metal and excess material, increasing costs and environmental impact. In contrast, additive technologies build components layer by layer, using only the necessary amount of material. This not only contributes to a more sustainable manufacturing approach but also enhances cost-effectiveness. As industries seek to maximize efficiency and sustainability, the implementation of additive manufacturing is becoming an essential aspect of modern machining practices.

As the manufacturing landscape continues to evolve, the necessity for a workforce trained in emerging technologies is paramount. Efforts to reskill and upskill employees are becoming essential to meet the demands posed by advancements such as artificial intelligence and automation. With many industrial-era employees finding their skills outdated, organizations must prioritize lifelong learning opportunities. Community colleges and vocational training programs are pivotal in this transition, offering tailored courses that align with the needs of modern industries.

The integration of digital learning platforms plays a crucial role in modern workforce development. By leveraging AI-driven personalized learning paths, companies can create customized training experiences that directly address skill gaps. This approach not only enhances technical capabilities but also fosters the development of essential soft skills that are increasingly valued in today’s workplace. Organizations that commit to continuous learning and development will position themselves to thrive in a competitive market, ensuring that their workforce is equipped to handle the challenges and opportunities of the future.