Moulds play a pivotal role in the manufacturing sector, influencing not just the quality of products but also the overall efficiency of production processes. According to industry statistics, approximately 30% of manufacturing time can be lost due to inefficient mould design and maintenance practices. A recent report by the American Society for Quality indicates that optimizing moulds can enhance production efficiency by up to 20%, directly impacting the bottom line of manufacturing firms. Furthermore, the global mould market is projected to reach $10 billion by 2025, reflecting the increasing awareness among manufacturers about the importance of high-quality moulds in maximizing productivity. As industries continue to evolve, understanding the intricate relationship between moulds and manufacturing efficiency becomes essential for sustaining competitiveness in a rapidly changing marketplace.

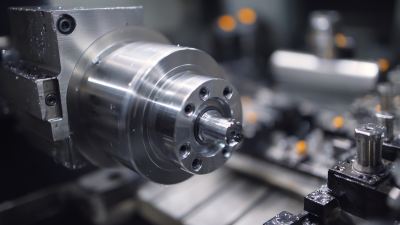

Moulds, essential tools in the manufacturing process, are used to shape materials into desired forms. In essence, a mould is a hollow block that is filled with liquid or pliable materials to create objects once the material solidifies or hardens. There are various types of moulds, each designed to meet specific requirements in industrial applications. Common types include injection moulds, blow moulds, and compression moulds, each varying in complexity and function. Injection moulds, for instance, are widely used in the plastic industry for mass-producing intricate parts.

The choice of mould type can significantly affect manufacturing efficiency. Different materials and mould designs can result in variations in cycle times, lead to less waste, and influence the precision and quality of the final product. For instance, efficient mould configurations can minimize the time needed for cooling and solidifying, allowing manufacturers to optimize production rates and reduce downtime. As industries continue to evolve, understanding the types and uses of moulds becomes increasingly crucial for improving overall production efficiency and meeting market demands.

The injection molding industry is witnessing significant growth, with the market projected to rise from USD 365.22 billion in 2024 to USD 580.44 billion by 2033, at a 4.74% CAGR. This rapid expansion underlines the vital role that effective mould design and manufacturing efficiency play in the overall production process. Key industry statistics highlight that optimizing mould usage not only enhances production speeds but also improves product quality, thereby driving down costs and waste.

To tackle inefficiencies and high error rates in traditional design processes, the shift towards technology-driven solutions has become essential. Implementing a knowledge graph-driven intelligent data-enabled design system can revolutionize how mould designs are created and refined. This system leverages deep semantic understanding and intelligent decision support to streamline complex design tasks, ultimately leading to more accurate and efficient production methods.

Tips:

1. Focus on maintaining precise data management to enhance decision-making processes in mould design.

2. Invest in advanced molding technologies that support customization and rapid prototyping, minimizing production delays.

3. Regularly analyze industry trends and statistics to align your practices with market demands and innovation.

The quality of moulds plays a crucial role in determining production costs and efficiency in manufacturing processes. High-quality moulds are essential as they directly influence the precision and consistency of the final products. When manufacturers invest in well-designed moulds, they often see a reduction in material waste and defects, leading to lower production costs. Conversely, poor-quality moulds can result in frequent machine downtimes and costly rework, ultimately driving up the overall operational expenses.

Additionally, the time required to complete production cycles is significantly impacted by mould quality. Efficient moulds facilitate quicker cooling and solidification times, which enhances the throughput of manufacturing operations. When moulds fail to perform optimally, manufacturers face delays that can bottleneck production schedules and affect market responsiveness. Therefore, understanding the relationship between mould quality and production metrics is essential for manufacturers aiming to maximize efficiency and reduce expenses in today’s competitive landscape.

In the world of manufacturing, optimizing moulds is critical for enhancing efficiency and productivity. Statistical reports indicate that over 30% of production time in moulding processes can be wasted due to improper mould management. By investing in advanced mould technology and refining the design, manufacturers can see a reduction in operational downtime and an increase in output. For instance, studies reveal that using simulation software during the design phase can improve mould performance by up to 25%.

To maximize the effectiveness of moulds, manufacturers should adopt best practices such as regular maintenance and the implementation of precision engineering techniques. This includes conducting periodic inspections and utilizing advanced materials, which can prolong the life cycle of moulds and maintain consistent quality. According to recent industry data, companies that implement a structured mould maintenance program report a 15% increase in production efficiency.

Tips: Regularly monitor mould temperature and pressure to identify discrepancies early, invest in training operators on the latest mould technologies, and leverage data analytics to inform decision-making regarding mould design and usage. These proactive steps can significantly contribute to a streamlined manufacturing process and improved overall efficiency.

Innovation in mould technology is rapidly transforming manufacturing efficiency across various industries. According to the recent "2024 China Consumer Electronics Industry Research Report," the consumer electronics sector is witnessing increased demands that require highly efficient production methods. In this context, advanced mould technologies like additive manufacturing and 3D printing are set to play crucial roles. By 2025, the global 3D printing industry is anticipated to host significant events that will showcase these innovations, emphasizing their importance in enhancing production capabilities while reducing time and costs.

Furthermore, the industrial machinery segment continues to evolve, with market growth projected from 6,313.62 billion yuan in 2019 to 7,128.86 billion yuan by 2024. This growth highlights the pressing need for manufacturers to adopt smarter solutions in their operations. Companies that strengthen their injection moulding competitiveness, as seen in facilities like Qingdao Haitai Keji, illustrate the shift toward utilizing state-of-the-art machinery and automated systems. These advancements not only increase efficiency but also enhance product quality, paving the way for a more robust manufacturing landscape in the coming years.

This bar chart illustrates the trend of manufacturing efficiency attributed to advancements in mould technology from 2018 to 2023. As shown, there is a consistent improvement in efficiency, reflecting the ongoing innovations in mould technology and their adoption within the industry.