In today's competitive manufacturing landscape, optimizing production processes is essential for achieving efficiency and profitability. The use of high-quality die mold components has become a critical factor in enhancing product quality and reducing lead times. According to a report by MarketsandMarkets, the global die and mold market is projected to reach $30 billion by 2025, emphasizing the increasing reliance on advanced die mold technology across various industries.

By integrating innovative die mold components into production workflows, manufacturers can significantly decrease production costs and turnaround times while improving the precision and durability of their products. This guide will explore effective strategies to optimize your production process through the strategic selection and implementation of die mold components, ensuring that your operations remain agile and competitive in an evolving marketplace.

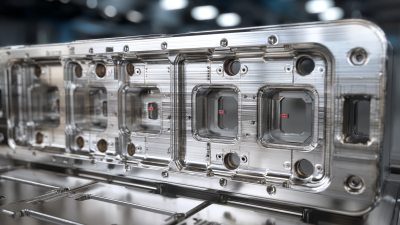

Die mold components play a crucial role in enhancing production efficiency across various manufacturing sectors, particularly in the automotive and consumer goods industries. According to a report by the International Institute for Advanced Manufacturing, the optimization of die mold design can lead to a reduction in production time by up to 30%. This significant decrease not only accelerates the overall production cycle but also minimizes resource waste, thereby improving the return on investment for manufacturers.

Furthermore, the quality of die mold components directly impacts the precision and reliability of the final products. A recent study from the Society of Manufacturing Engineers indicates that high-quality molds can reduce defects by approximately 25%, which translates to lower costs associated with rework and scrap. As industries increasingly focus on lean manufacturing principles, understanding the importance of die mold components becomes imperative for sustaining competitive advantages in a fast-paced market. By investing in state-of-the-art materials and technologies for die molds, manufacturers can achieve higher efficiency, resulting in enhanced profitability and market responsiveness.

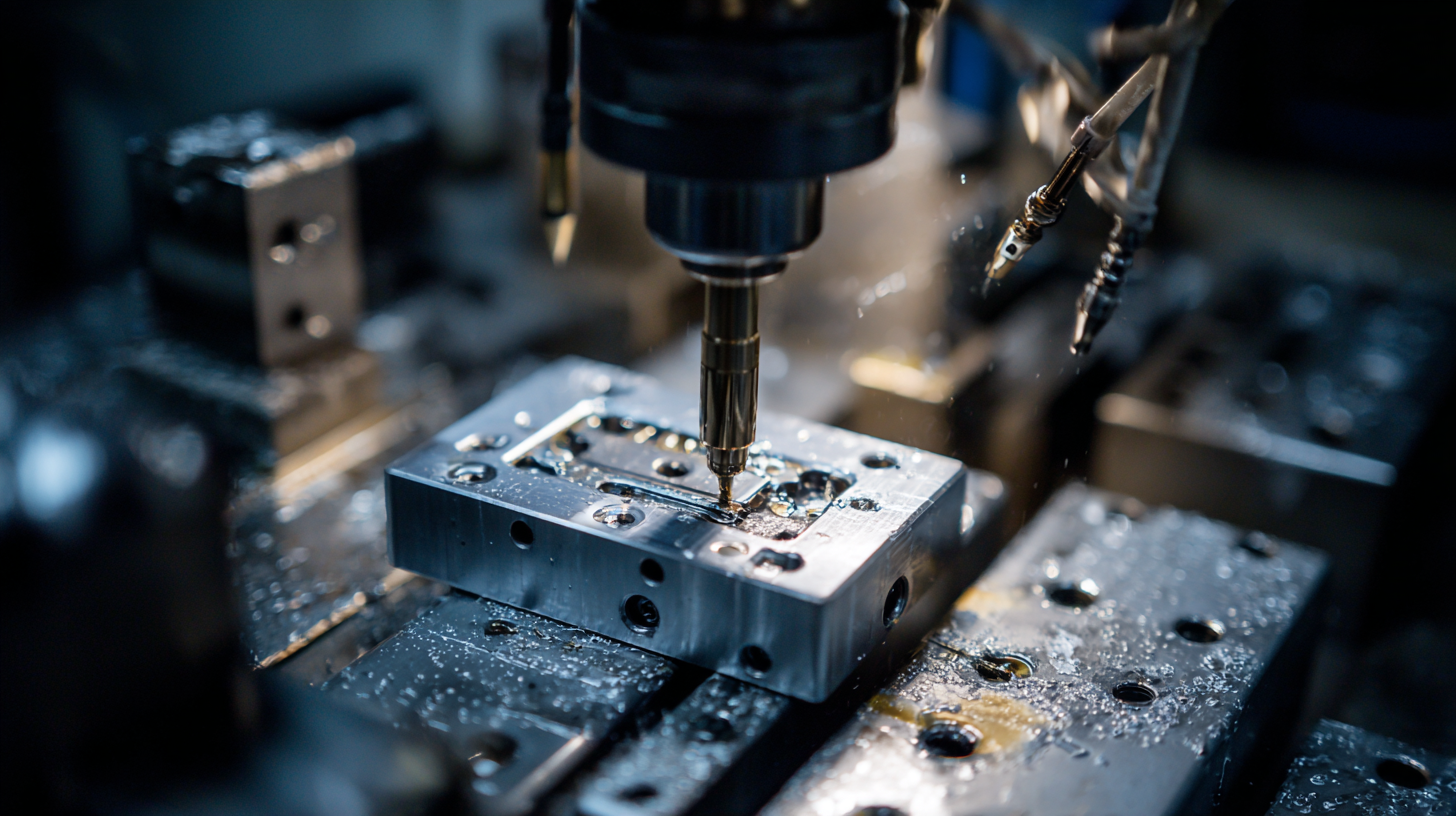

In today's production landscape, manufacturers face significant challenges related to labor shortages, sustainability, and the increasing complexity of products. The advent of automation and artificial intelligence (AI) has been pivotal in addressing these issues. For example, the market for automation in injection molding is projected to grow significantly, with investments in advanced machinery increasing as companies seek to enhance efficiency and reduce dependence on manual labor. According to industry data, the global injection molding machine market is expected to reach a valuation of $16 billion by 2025, driven by the demand for automation solutions.

Moreover, the rise of chiplet-based products necessitates precision in die dimensions during assembly processes. Small variances in die size and bump pitch can lead to substantial challenges in manufacturing, making it essential for facilities to adopt die mold components that accommodate these specifications. The integration of selective laser melting (SLM) technology allows for the fabrication of intricate metal composites that help overcome these assembly hurdles, further illustrating the transformative potential of advanced mold components in ensuring consistent quality and efficiency. As companies leverage these innovations, they can better navigate the complexities of modern production demands.

When selecting die mold components for optimization, it is essential to prioritize material quality. High-grade materials not only enhance the durability of the molds but also improve the precision of the production process. For instance, hardened steel and advanced alloys can withstand higher temperatures and pressures, thereby reducing wear and tear. This selection directly influences the longevity of the molds, leading to fewer replacements and less downtime in manufacturing.

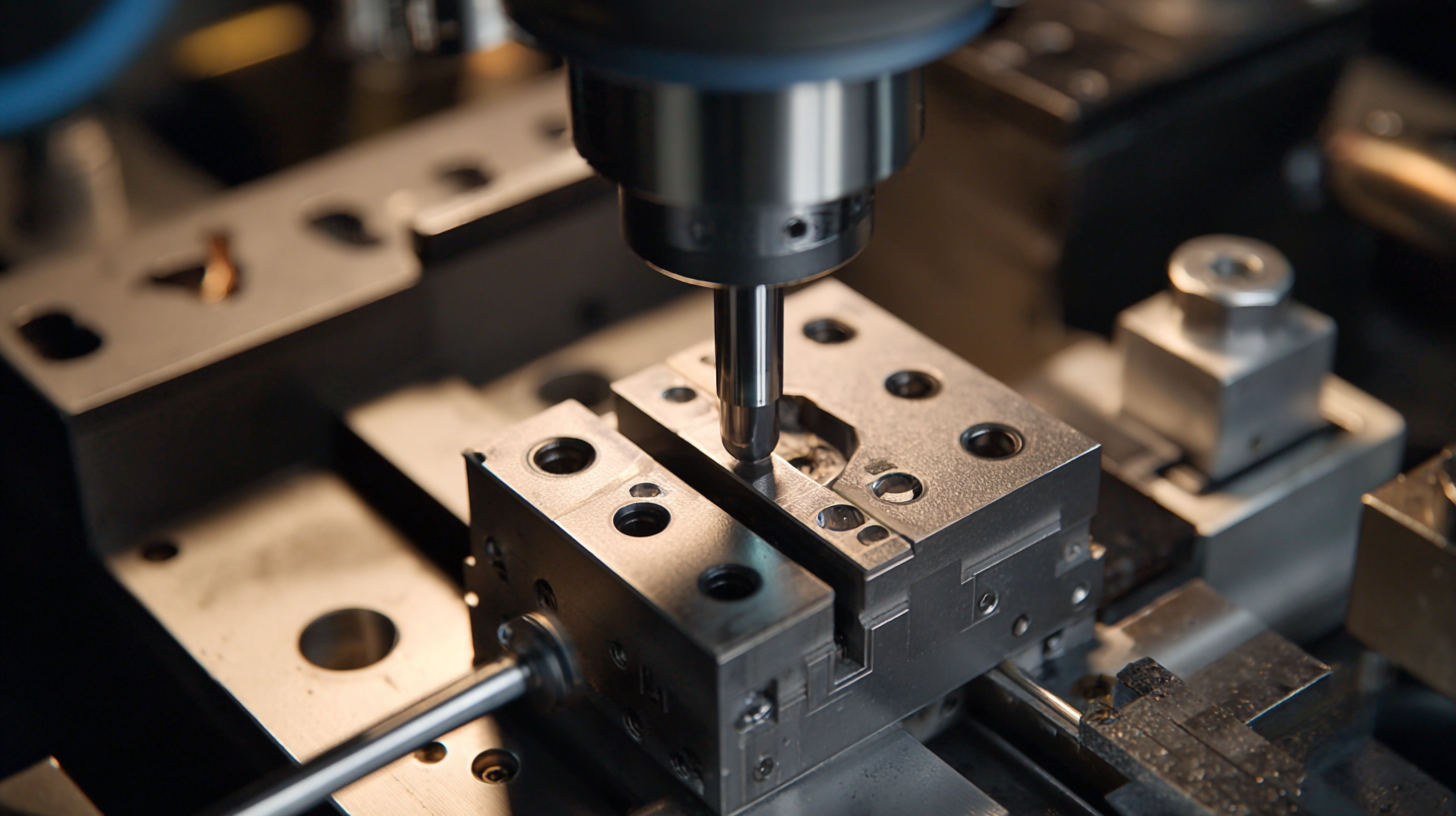

Another critical factor is the geometry and design of the mold components. A well-designed mold can facilitate smoother material flow and reduce the chance of defect creation. Considering elements such as draft angles, undercuts, and surface finish can significantly impact the efficiency of the molding process. Combining design optimization with advanced simulation tools can help anticipate potential issues, allowing for adjustments before the actual production begins. Emphasizing these key factors in your selection process will ensure a more effective and optimized production workflow.

Maintaining and upgrading die mold components is crucial for optimizing production processes. One of the best practices in this area is the regular application of high-quality mold grease. Recent industry reports indicate that switching to synthetic greases can significantly enhance die performance by reducing friction and wear on components. For instance, manufacturers have noted up to a 30% increase in efficiency due to fewer unplanned downtimes attributed to lubrication failures.

Incorporating advanced lubricants not only prolongs the life of the die but also contributes to smoother operations in high-stress environments. A notable case involved an injection molder who transitioned to a new synthetic grease, allowing them to keep a challenging die running consistently while cutting downtime by a remarkable percentage. Furthermore, maintaining optimal operational temperatures through effective cooling techniques and regular inspections can prevent material buildup, ensuring a higher quality of output and better overall machine health. Regular upgrades, guided by performance metrics, are essential to keep up with the evolving demands of production processes.

The integration of innovative technologies in die mold components significantly enhances production efficiency and product quality. Advanced materials such as high-performance alloys and composites are now being utilized to create molds that withstand extreme conditions while reducing wear and tear. These materials not only extend the lifespan of the molds but also enable faster production cycles, allowing manufacturers to meet growing market demands with less downtime.

Additionally, the incorporation of smart technologies, such as IoT devices and AI-driven analytics, transforms the traditional approaches to die mold production. With real-time monitoring of mold conditions and predictive maintenance capabilities, manufacturers can anticipate issues before they become critical, minimizing unexpected failures. This proactive strategy not only boosts productivity but also optimizes resource allocation, further streamlining the production process. As these innovative techniques continue to evolve, businesses can look forward to enhanced efficiency and improved outcomes in their manufacturing operations.