In the rapidly evolving landscape of manufacturing, precision and quality are paramount, particularly for global buyers seeking dependable machining services. As we approach the year 2025, an in-depth market analysis reveals trends and innovations that are shaping the future of the machining industry. With advancements in technology, including automation and smart manufacturing, businesses are now equipped to meet the increasing demand for customized and high-quality machined components. This blog will explore the key drivers influencing the market, the importance of adopting cutting-edge techniques, and how global buyers can unlock unparalleled precision and quality through strategic partnerships with leading machining service providers. By navigating these dynamics, companies can ensure they remain competitive in a marketplace defined by rapid change and heightened consumer expectations.

Chinese manufacturing has long been a cornerstone of the global supply chain, and its potential is now more apparent than ever as it adapts to the demands of international buyers. With advancements in technology and a commitment to quality, Chinese manufacturers are raising the bar in precision machining services. They leverage state-of-the-art equipment and materials, ensuring that even the most intricate components meet the rigorous standards of global customers. This evolution is creating opportunities for collaboration and innovation across industries, from aerospace to automotive.

Furthermore, the ongoing investment in research and development within China's manufacturing sector highlights its dedication to unlocking even greater capabilities. By employing highly skilled labor and integrating smart manufacturing solutions, Chinese companies are positioning themselves as leaders in efficiency and quality. This shift not only enhances their competitive edge but also opens the door for global buyers to access top-tier products at advantageous prices. As the landscape of manufacturing continues to change, embracing the potential of Chinese manufacturers is essential for businesses aiming to thrive in the global market.

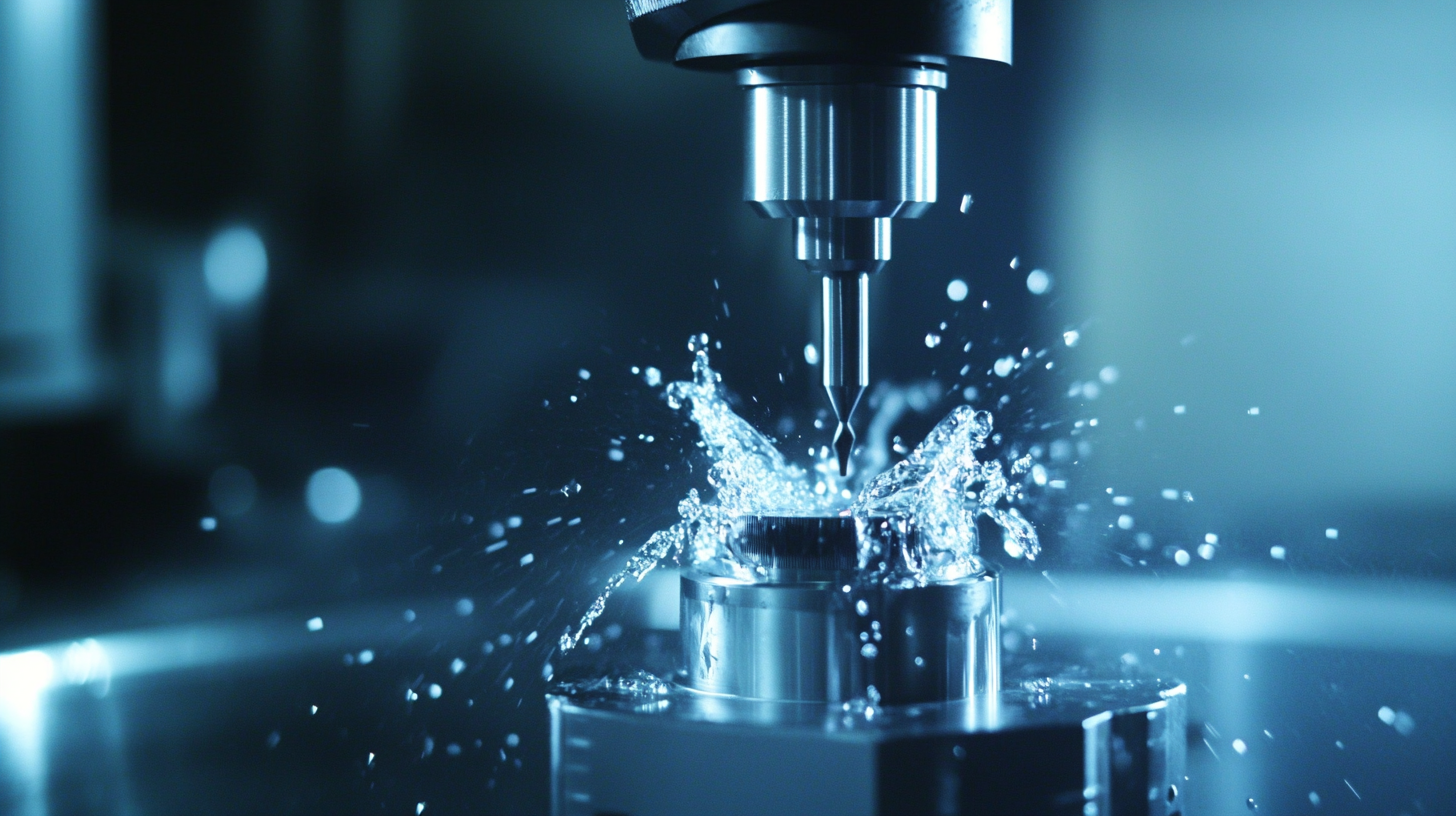

CNC machining has emerged as a game changer in achieving precision across various industries. As manufacturing continues to evolve, the significance of advanced cutting fluids and tools cannot be understated. These innovations enhance machining efficiency and prolong tool life, aligning perfectly with the increasing demands for accuracy and reliability in component designs. The integration of cutting-edge technologies contributes to a more productive manufacturing environment, making CNC machining indispensable for global buyers looking for quality and precision.

As industries face a surge in demand, particularly with the revival of U.S. manufacturing and expanding markets like Saudi Arabia, the role of CNC machining is set to expand. The rise of artificial intelligence in machining processes promises to revolutionize manufacturing, driving accuracy to unprecedented levels. With projections indicating substantial growth in the precision tool market, companies are investing in next-generation CNC technologies to stay competitive. Enhanced precision machining services are essential for meeting the evolving needs of manufacturers and maintaining high standards in quality across various sectors.

Quality assurance standards play a vital role in establishing trust between machining service providers and global buyers. In today's competitive manufacturing landscape, adherence to strict quality benchmarks not only ensures the precision of machining processes but also enhances the overall reliability of the products delivered. Buyers are more inclined to choose suppliers who demonstrate a commitment to high-quality standards, such as ISO certifications or industry-specific benchmarks, as these indicators often correlate with superior craftsmanship and reduced defects.

Furthermore, these standards foster transparency in the production process. By implementing rigorous quality checks and balancing precision with consistency, machinists can provide detailed documentation of their adherence to these standards, reassuring clients regarding the integrity of their orders. This commitment to quality not only strengthens buyer confidence but also nurtures long-term partnerships, as buyers are more likely to return to vendors that consistently meet or exceed their quality expectations. Thus, by prioritizing quality assurance, machining services can differentiate themselves in the marketplace, appealing to a discerning global clientele.

When evaluating cost efficiency in machining services, Chinese providers often surface as competitive players in the global market. Their ability to combine advanced technology with low labor costs allows for the production of high-quality components at a fraction of the price compared to Western manufacturers. This financial advantage has attracted international buyers seeking reliable and cost-effective solutions for their machining needs. However, it is crucial to consider not just the price but also the precision and quality that these services offer.

In contrast, global competitors emphasize innovative manufacturing practices and stringent quality control standards to maintain their market position. While they may command higher prices, the value provided through superior craftsmanship and consistent output is often deemed worth the investment. As buyers navigate the complex landscape of machining services, understanding these dynamics can aid in making more informed decisions that balance cost with quality, ensuring that they select the best provider that meets their needs.

As we move closer to 2025, the machining industry is set to undergo transformative changes driven by emerging technologies. The projected growth of the global CNC machine market from $101.22 billion in 2025 to $195.59 billion by 2032 highlights the increasing demand for precision and quality in manufacturing processes. Key trends such as advanced automation, IoT-enabled machinery, and AI-driven insights are revolutionizing how manufacturers operate. These innovations not only enhance efficiency but also address skill gaps in the workforce.

To thrive in this evolving landscape, manufacturers should prioritize investments in digital transformation. Implementing smart technologies can streamline operations, reduce waste, and optimize production cycles. For instance, integrating AI into CNC systems enables predictive maintenance, leading to decreased downtimes and improved accuracy.

Tips for Manufacturers: