In the world of manufacturing, precision and efficiency are paramount, and one of the essential tools that embodies these principles is the press mold. According to industry expert John Smith, a renowned figure in manufacturing technology, "The use of press molds revolutionizes the way components are produced, allowing for greater accuracy and faster turnaround times." This statement underscores the role of press molds as a pivotal element in various manufacturing processes, where they are utilized to shape materials under high pressure, ensuring consistency and quality in the final products.

Press molds are not just tools but are integral to the optimization of production lines across multiple sectors, from automotive to consumer goods. By employing advanced techniques in mold design and production, manufacturers can achieve intricate shapes and designs that would be difficult or even impossible to create using traditional methods. As industries strive for innovation and cost-effectiveness, the adoption of press molds continues to rise, highlighting their significance in shaping the future of manufacturing.

In this exploration of press molds, we will delve into their definition, applications, and the transformative impact they have made in modern manufacturing landscapes. Understanding the intricacies of press molds will not only provide insight into their operational mechanics but also illustrate their indispensable role in driving efficiency and quality in production processes.

A press mold, commonly utilized in manufacturing processes, serves as a critical tool for shaping materials into specific forms. Defined as a hollow form or cavity, a press mold is typically made from metal and designed to withstand high pressures while accurately producing components with tight tolerances. The purpose of using a press mold is to facilitate mass production while ensuring repeatability and consistency in the final products. According to a report by MarketsandMarkets, the global market for injection molding, which heavily relies on press molds, is projected to reach USD 367.2 billion by 2026, reflecting the growing demand for precision-engineered components in various industries.

The use of press molds is especially prevalent in sectors such as automotive, aerospace, and consumer goods, where the need for durable and lightweight parts is paramount. Press molds allow manufacturers to mold materials, including plastics and metals, at high speeds, significantly enhancing production efficiency. Furthermore, their ability to create complex geometries minimizes material waste and reduces the overall manufacturing cost. As highlighted in a 2021 industry analysis by Grand View Research, the increasing adoption of smart manufacturing technologies is expected to boost the use of advanced press molds, driving innovation and enhancing productivity across various manufacturing sectors.

Press molds are essential tools in various manufacturing processes, utilized in shaping and forming materials through intense pressure. There are several types of press molds, each designed for specific applications, allowing manufacturers to achieve desired shapes and dimensions efficiently.

One common type of press mold is the injection mold, primarily used in the production of plastic parts. In this process, thermoplastic materials are heated until they become pliable, then injected into a mold cavity under high pressure. This method is prevalent in industries such as automotive and consumer electronics, where precision and high-volume production are crucial.

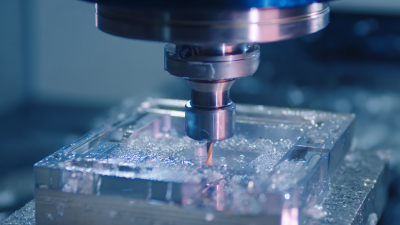

Another type is the die mold, often employed in metal forming processes. Die molds can withstand significant pressure and are typically used to shape metals into components for machinery and structural applications. Stamping and forging processes are common examples, where materials are formed into intricate parts that meet strict tolerance requirements. Each type of press mold serves a unique purpose, reflecting the diverse needs of modern manufacturing.

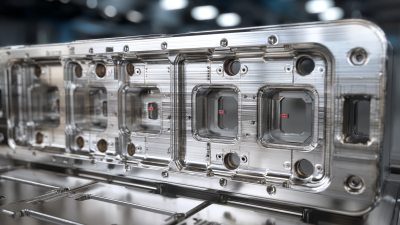

Press molds play a crucial role in various manufacturing processes, especially in industries such as automotive, aerospace, and consumer goods. The manufacturing process involving press molds typically begins with the creation of a mold, which is often made from durable materials like steel or aluminum. This mold is designed to shape the material that will be formed, ensuring that the final product meets precise specifications.

Once the mold is ready, the manufacturing process continues with the heating of the raw materials to a malleable state. This can involve thermoplastics, metals, or composites, depending on the desired outcome. The heated material is then placed into the press mold, where immense pressure is applied to form the material into the desired shape.

After cooling or curing, the mold is opened, and the finished product is removed. This method not only allows for high precision and consistency in manufacturing but also enhances production efficiency by enabling the mass production of complex shapes with minimal waste.

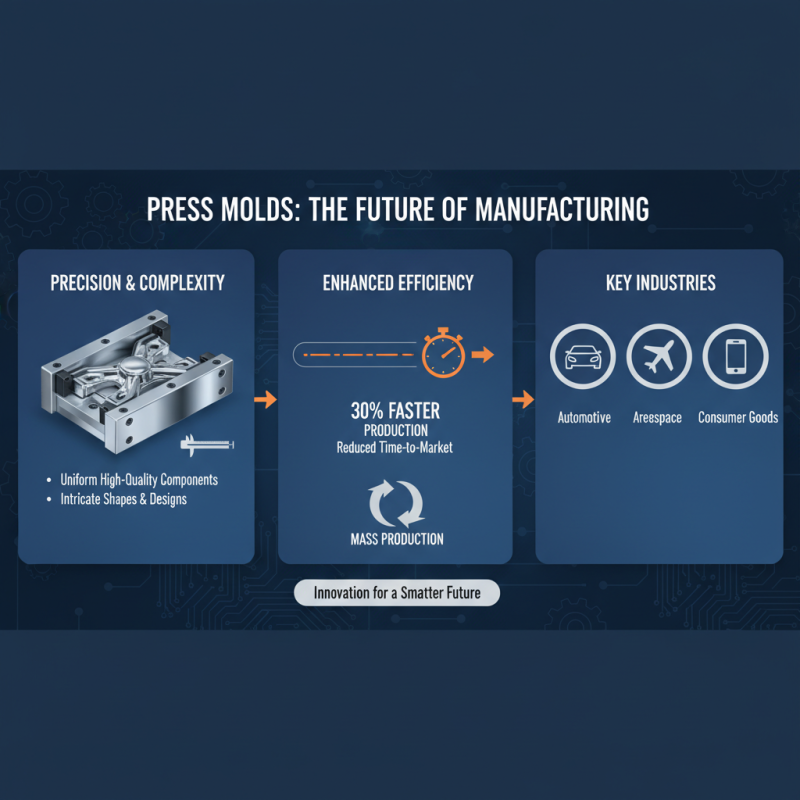

Press molds are integral to many manufacturing processes, particularly in industries such as automotive, aerospace, and consumer goods. They allow for the mass production of high-quality components with uniformity, significantly enhancing production efficiency. One of the primary advantages of using press molds is their ability to produce complex shapes that are consistent in dimension and quality. According to a recent industry report, products made with press molds can exhibit a 30% reduction in production times compared to traditional manufacturing methods, leading to faster time-to-market for companies.

Additionally, press molds contribute to material savings and reduce waste, which is increasingly important in today’s eco-conscious market. Studies show that using press molds can lead to up to a 20% decrease in surplus material during production. This not only lowers material costs but also minimizes the environmental impact, aligning with sustainability goals that many manufacturers are striving for.

Tips: To maximize the benefits of press molds, manufacturers should consider investing in advanced mold design software and simulation tools. This can help in understanding the flow of materials and identifying potential defects early in the design process. Moreover, regular maintenance of molds will ensure longevity and consistent performance, further enhancing production efficiency. Keeping molds clean and well-lubricated can also lead to improved output quality and reduced downtime.

Press molds are widely utilized across various industries due to their efficiency and versatility in manufacturing processes. One of the most prominent sectors leveraging press molds is the automotive industry. Here, press molds are critical in producing components such as body panels and interior parts, allowing for high precision and consistency. The ability to mass-produce parts quickly means that manufacturers can keep up with the fast-paced demands of vehicle assembly lines while ensuring quality control.

Another significant area that employs press molds is the consumer goods sector. Items such as kitchenware, appliances, and furniture components are frequently created using this method. The process allows for intricate designs and shapes, which can enhance the aesthetics and functionality of everyday products. Additionally, industries focused on electronics and packaging also benefit from press molds to create specialized casings and containers that protect sensitive components. The efficiency and adaptability of press molds make them indispensable in these diverse sectors, driving innovation and productivity.

This chart illustrates the percentage of various industries that utilize press molds in their manufacturing processes.