In the ever-evolving landscape of manufacturing, the selection of the right die mold components is crucial for ensuring product quality and operational efficiency. According to recent industry reports, the global die and mold market is projected to reach approximately $82 billion by 2025, driven by increasing demands in sectors such as automotive and consumer electronics. As such, understanding the various types of die mold components—ranging from cores and cavities to ejector systems—is essential for optimizing production processes. With the right selections, manufacturers can significantly reduce cycle times, improve precision, and enhance the overall durability of their molded products. This blog will guide you through the key considerations and criteria that should be taken into account when choosing the best die mold components for your specific project needs.

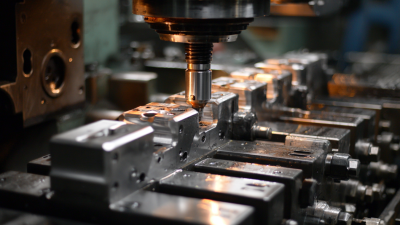

When embarking on a project that involves die mold manufacturing, understanding the importance of material selection is crucial. The type of material used for die mold components can significantly impact the performance, durability, and cost-effectiveness of the final product. For instance, materials such as steel offer high strength and resistance to wear, making them ideal for high-volume production runs. On the other hand, aluminum is lightweight and can be machined with ease, which can be advantageous for prototyping or small runs where time is a critical factor.

Additionally, the specific application of the die mold must be considered when selecting materials. Factors such as thermal conductivity, corrosion resistance, and the specific characteristics of the plastic or metal being molded play a pivotal role in material choice. For instance, if the die will be used for molding materials that encounter high temperatures, it is vital to select heat-resistant alloys to prevent deformation. Thus, a thorough understanding of both the material properties and the project requirements will lead to more efficient production processes and ultimately, a successful outcome for the project.

When selecting die mold components for your project, understanding the key factors that influence die mold design efficiency and performance is crucial. One of the most significant factors is material choice. The right materials can enhance durability and reduce wear, leading to prolonged lifespan and consistent output. Selecting a high-quality steel or aluminum alloy specifically designed for mold-making can yield better thermal conductivity and lower cycle times, elevating overall production rates.

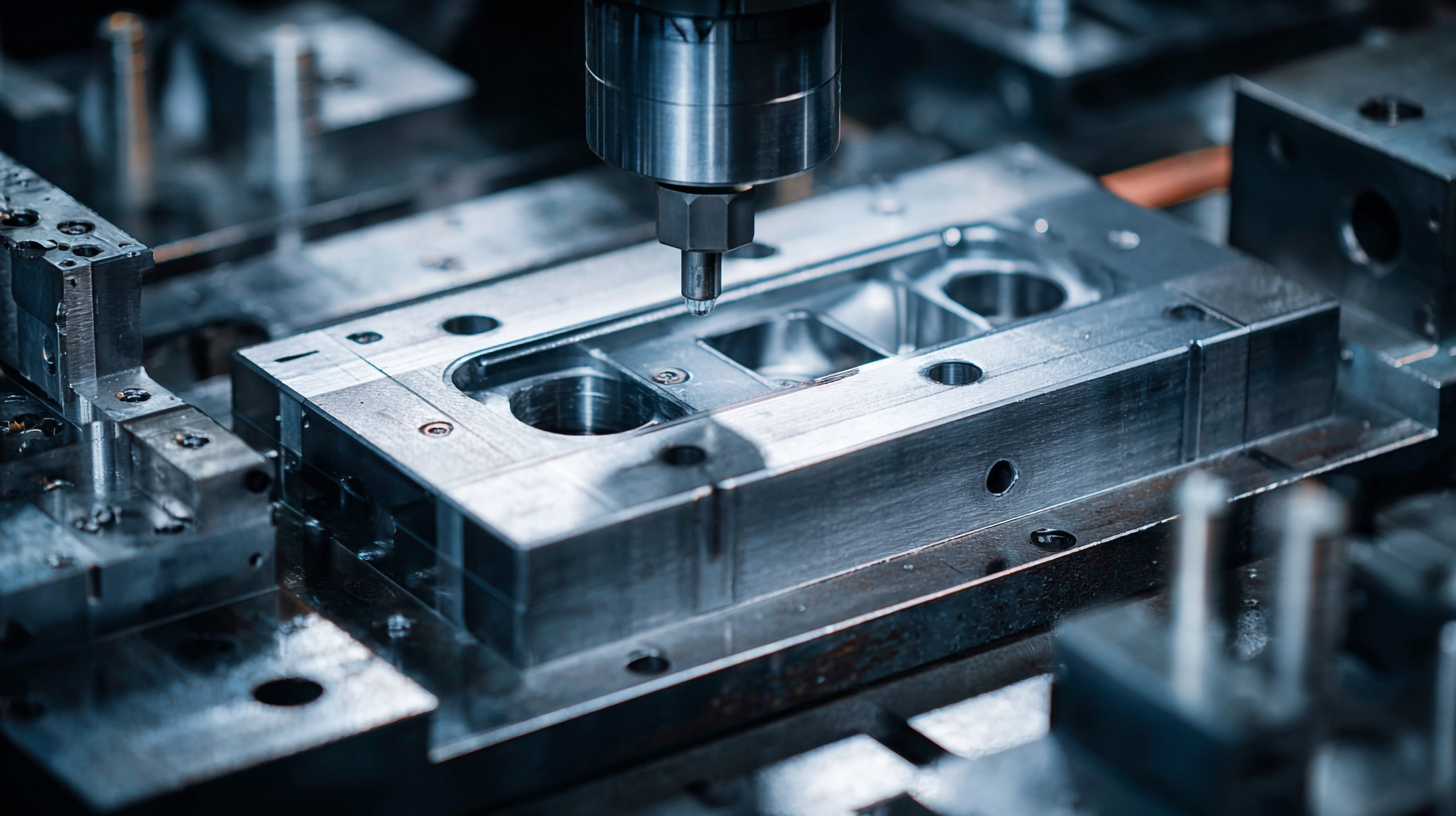

Another vital aspect is the precision of the components. Tightly toleranced parts ensure better fitment and alignment, minimizing the potential for defects during the molding process. Incorporating components that allow for easy adjustments can also enhance the mold's adaptability and efficiency. Remember, the effectiveness of cooling channels affects not only the cycle time but also the quality of the final product. Emphasizing these factors during the design and selection process will help you achieve optimal performance and efficiency in your die mold projects.

| Component | Material Type | Durability Rating | Cost per Unit | Application Suitability |

|---|---|---|---|---|

| Ejector Pins | Alloy Steel | Excellent | $1.50 | High-volume production |

| Injection Mold Base | Pre-hardened Steel | Very Good | $350.00 | Medium to high-volume |

| Cavity Inserts | Tool Steel | Good | $75.00 | Low to medium-volume |

| Cooling Channels | Stainless Steel | Excellent | $50.00 | All applications |

| Gate Inserts | Boron Steel | Good | $45.00 | Medium-volume production |

When selecting die mold components for a project, understanding tolerances and surface finishing techniques is essential for achieving optimal results. Surface quality is defined by three critical characteristics: lay, surface roughness, and waviness. High-precision components often require strict tolerances to ensure proper fit and function, particularly in industries such as aerospace and automotive. Recent advancements in metal additive manufacturing (MAM) techniques, particularly laser powder bed fusion (LPBF), have revolutionized the way surfaces can be finished. The LPBF process allows for intricate geometries and a variety of steel and iron-based alloys, which, as research shows, can lead to microstructural improvements and enhanced mechanical properties.

When selecting die mold components for a project, understanding tolerances and surface finishing techniques is essential for achieving optimal results. Surface quality is defined by three critical characteristics: lay, surface roughness, and waviness. High-precision components often require strict tolerances to ensure proper fit and function, particularly in industries such as aerospace and automotive. Recent advancements in metal additive manufacturing (MAM) techniques, particularly laser powder bed fusion (LPBF), have revolutionized the way surfaces can be finished. The LPBF process allows for intricate geometries and a variety of steel and iron-based alloys, which, as research shows, can lead to microstructural improvements and enhanced mechanical properties.

Moreover, the importance of surface finishing cannot be overstated. A study highlights that traditional methods of surface finishing are often labor-intensive and time-consuming, presenting challenges in uniformity and quality control. Innovative approaches, such as automated post-processing techniques, are being explored to address these bottlenecks in additive manufacturing. For instance, the fluidised bed finishing process is gaining traction for its efficiency in treating complex geometries found in aeronautical applications, where surface integrity is paramount. As the field continues to evolve, understanding these methodologies will be crucial for selecting the right die mold components that meet stringent performance and aesthetic standards.

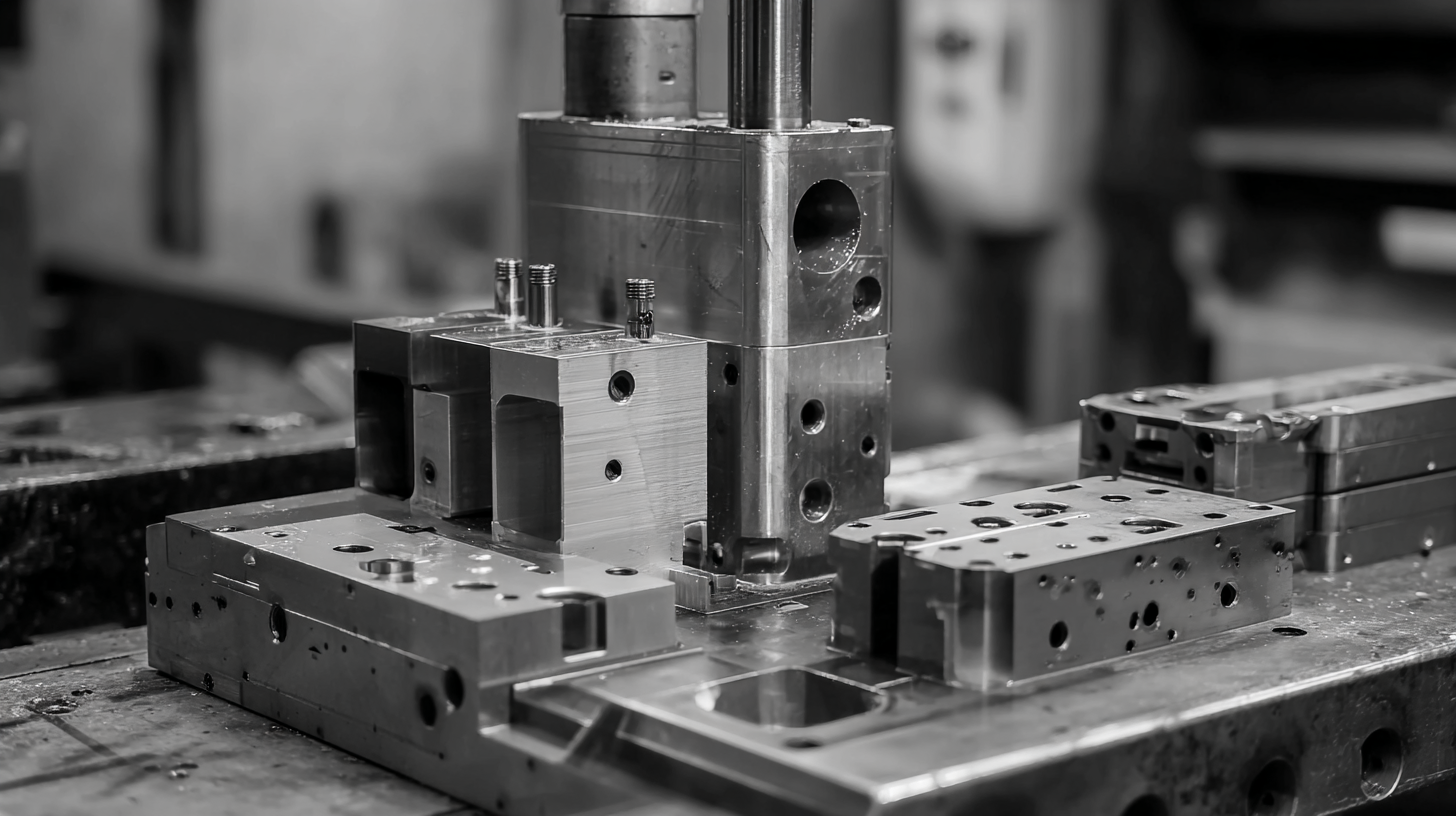

When selecting die mold components for your project, conducting a thorough cost-benefit analysis of different types is crucial. Recent reports indicate the low pressure die casting machines market is projected to grow from USD 2.15 billion in 2024 to USD 2.98 billion by 2030. This growth reflects a rising demand for high-precision components, particularly in industries like automotive and aerospace. The low pressure casting method is gaining traction due to its ability to produce components with superior mechanical properties, which is essential for meeting the stringent requirements of modern applications.

Moreover, in the realm of manufacturing, techniques like DMAIC and Lean Six Sigma are becoming increasingly vital for defect reduction. An empirical case study highlighted the effectiveness of these methodologies in improving production processes and minimizing waste. Incorporating the findings from such methodologies can lead to significant cost savings and improved reliability in die mold component production. As the global tooling market continues to evolve, with projections indicating substantial growth segmented by product types, making informed decisions based on comprehensive analysis can significantly enhance project outcomes and competitiveness in the marketplace.

When selecting die mold components for various projects, emerging technologies play a crucial role in material choice and manufacturing processes. Recent studies highlight the importance of multi-criteria decision-making frameworks in the development of products tailored for specific needs, such as creating toys for children with autism. For instance, research indicates that considering both technical properties and design-related aspects is essential in selecting appropriate materials that not only ensure durability but also enhance user experience.

In the automotive sector, advancements in lightweight materials have gained significant momentum. A systematic review identifies light alloys and high-strength steels as key components in the manufacturing of next-generation vehicles, emphasizing that the integration of these materials can lead to improved fuel efficiency and overall performance. Additionally, innovations in lightweight composite structures offer promising avenues for reducing weight without compromising structural integrity, which is critical in enhancing energy efficiency across industries.

The trend toward sustainable materials is also reshaping die mold component selection. Emerging building materials exhibit enhanced performance and innovative production technologies, allowing manufacturers to meet the growing demand for environmentally friendly solutions. Research indicates that technology assessment tools increasingly incorporate sustainability parameters, influencing material selection, and driving the development of more efficient, circular production methodologies.