Choosing the right press mold is crucial for manufacturing efficiency and product quality. According to industry data, over 70% of production failures can be traced back to mold-related issues. This statistic underscores the importance of meticulous mold selection. The right press mold not only enhances production speed but also reduces waste and costs.

When evaluating press molds, one must consider several factors. Material compatibility and design specifications are paramount. Statistics show that about 40% of manufacturers report issues related to mold wear and tear. This highlights the need for choosing durable materials that can withstand repeated use. However, many fail to realize the long-term impact of their choices.

Mold selection also requires reflection. Many businesses overlook the importance of consulting with experts. Valuable insights can guide decision-making and prevent costly mistakes. Investing time in research and expert advice can pay off significantly in the long run, ensuring that your press mold meets all manufacturing requirements effectively.

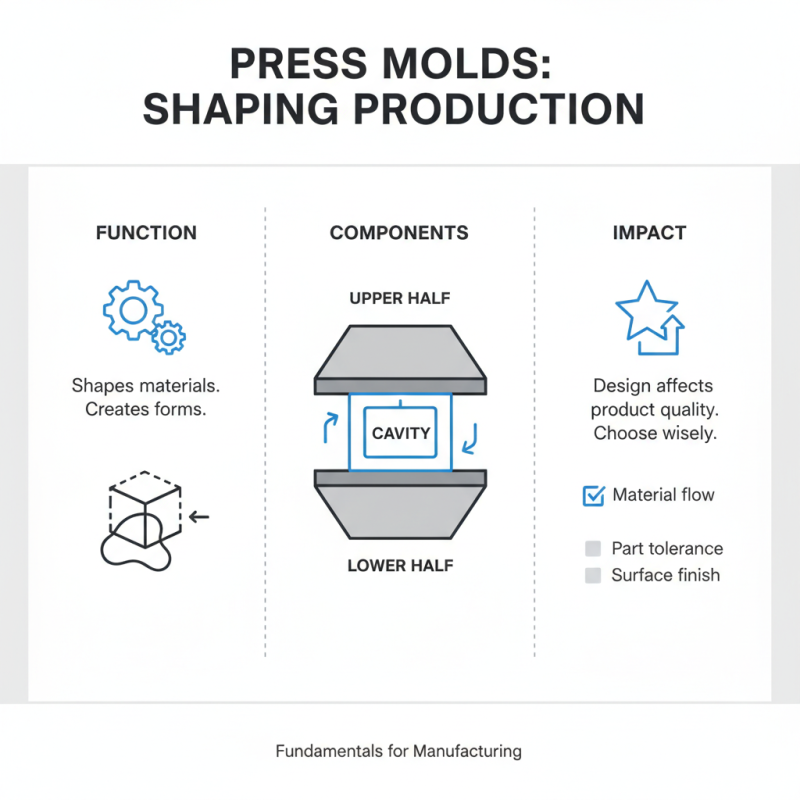

Press molds play a crucial role in manufacturing processes. They shape materials into desired forms. Understanding the fundamentals of press molds helps in selecting the right one for your production needs. A basic mold consists of two halves. These halves come together to create a cavity for the material. The design influences the final product's quality.

When choosing a press mold, consider the material compatibility. Not all molds suit every material. Molds can wear out over time, leading to defects. Regular maintenance is vital. Evaluate the production volume as well. High volume may require more durable molds. However, this also means a higher initial cost. Balance is key.

Mistakes can happen in mold selection. An improper choice can result in inefficiencies. Always reflect on past projects. What went well? What didn’t? Learning from experience leads to better decisions. Engaging with knowledgeable colleagues enhances understanding. This collaborative approach can prevent costly errors and improve outcomes.

Choosing the right press mold is crucial for your project. Start by identifying the specific needs for your applications. Think about the materials you will use. The type of material affects the mold design significantly. Budget constraints are another factor. Can you afford high-end materials or will you opt for more economical options?

Next, consider the production volume. Will you use the mold for small batches or large-scale production? High-volume runs need durable molds. However, for smaller projects, you might not need the same level of durability. It’s important to reflect on how often the mold will be used. Frequent use can wear molds down quickly, leading to issues.

Don’t forget about the complexity of parts. Intricate designs require more sophisticated molds. Think about how much detail is needed. Communications with mold makers can help clarify expectations. Misunderstandings can lead to costly mistakes. Be mindful of deadlines too; rushing can lead to less-than-ideal outcomes. Balancing needs, costs, and timelines is a real challenge but essential for success.

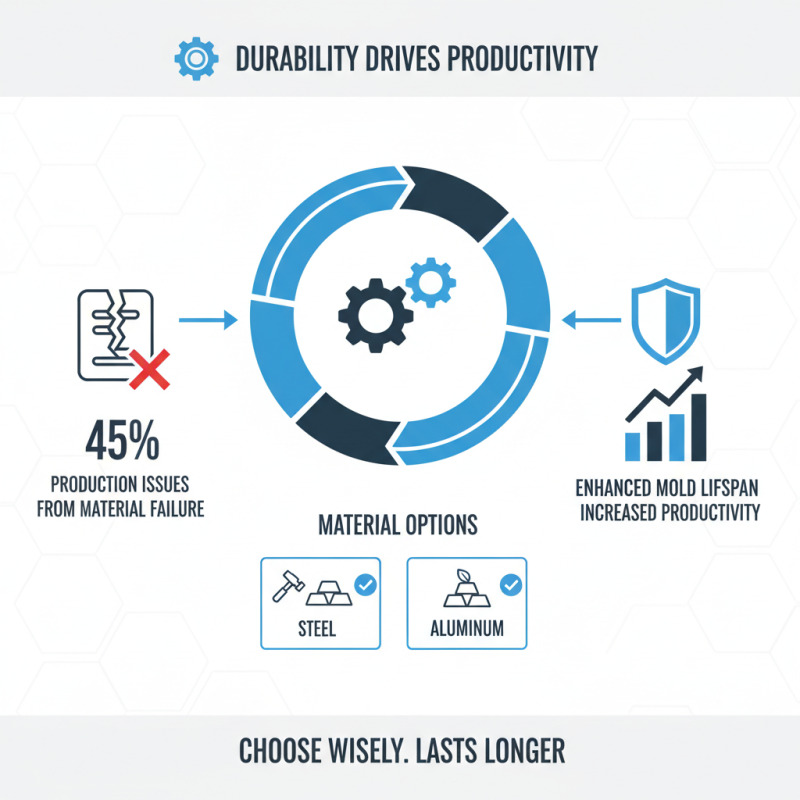

Choosing the right press mold involves careful consideration of material options. The durability of the mold is crucial for long-term productivity. According to a recent industry report, over 45% of production issues arise from material failure. Selecting materials such as steel or aluminum can enhance the lifespan of molds significantly.

Aluminum molds can be lighter and often suitable for low-volume production. They also offer good thermal conductivity. However, they may wear out faster under heavy usage. Steel molds, on the other hand, can withstand higher pressures and offer greater durability. A recent study indicated that steel molds can last up to 30% longer than their aluminum counterparts in high-demand environments.

However, don’t overlook the importance of suitability. Not all materials can handle specific manufacturing processes. For instance, thermoset plastics may not perform well with certain metals. It's essential to conduct material testing. Neglecting this step could result in costly errors. Analyzing compatibility will ultimately optimize production efficiency and reduce downtime. The right choice affects both the mold's performance and the final product's quality.

When selecting a press mold, understanding the design considerations is crucial for optimal functionality. Materials play a significant role. According to industry reports, choosing high-quality steel or aluminum can enhance durability. Steel molds, for instance, are more resistant to wear, increasing their lifespan significantly, which can reduce costs in the long run. However, this might increase initial investment.

Design shapes also influence performance. Complex geometries can present challenges during the manufacturing process. Inadequate design can lead to inconsistencies in the final product. According to a survey by a manufacturing association, over 40% of mold failures are due to design flaws. This emphasizes the importance of testing prototypes before full-scale production.

Cooling and heating systems are critical too. Effective thermal management can enhance cycle times. Reports suggest that molds with optimized cooling channels can reduce cycle time by up to 30%. But achieving the perfect balance can be challenging; poor design may lead to uneven cooling, causing defects. Fine-tuning these aspects requires careful analysis and sometimes trial and error. Ultimately, each decision impacts both efficiency and quality.

This chart illustrates the key design considerations that impact the functionality of press molds, including material selection, mold type, and cooling efficiency.

When selecting press molds, the choice of suppliers and manufacturers is crucial. A supplier's reliability can significantly impact the quality of your end products. Look for manufacturers with a solid reputation in the industry. Check reviews or testimonials. A well-established company often has better quality control measures in place.

Consider visiting the manufacturing facility if possible. This gives insight into their operations and standards. Some suppliers may offer competitive pricing, but cheaper isn't always better. Be wary of those who rush production. Rushed processes often result in defects. Quality assurance should never be compromised.

Communication is also key. Ensure the supplier is responsive to your inquiries. A lack of communication can lead to misunderstandings. It’s essential to discuss expectations clearly. Sometimes, you may find discrepancies between what was promised and what is delivered. Be prepared to address these issues. Ultimately, investing time in finding the right partner pays off in the long run.

| Criteria | Importance Level | Recommended Action | Notes |

|---|---|---|---|

| Material Quality | High | Ask for material certifications | Ensure high durability and performance |

| Supplier Reputation | High | Check reviews and testimonials | Look for long-standing suppliers |

| Customization Options | Medium | Discuss specific needs during consultation | Tailor to specific production requirements |

| Delivery Time | Medium | Verify lead times before placing orders | Avoid delays in production schedule |

| Post-Sale Support | High | Ensure support for troubleshooting | Important for ongoing maintenance |