Wire EDM service has revolutionized the manufacturing industry with its precision cutting abilities. Experts like John Smith, a prominent figure in EDM technology, once stated, “Wire EDM service allows for intricate designs that traditional machining can't achieve.” This highlights the core benefit of this technology.

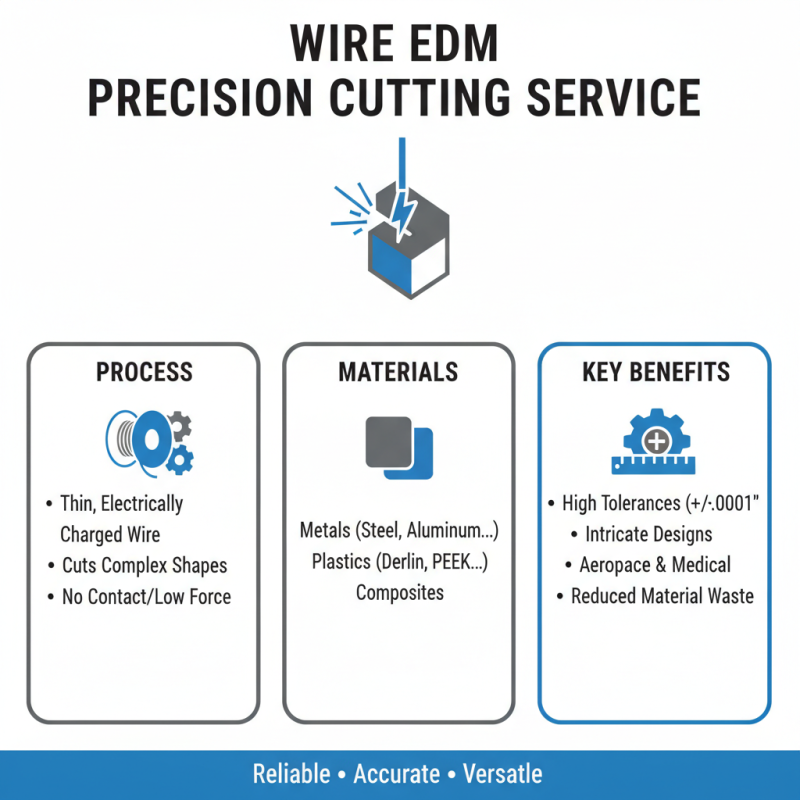

Wire EDM, or wire electrical discharge machining, utilizes a thin wire to cut through conductive materials. It is known for its accuracy, making it ideal for complex geometries. Many industries rely on wire EDM service to create parts that demand tight tolerances.

However, despite its advantages, the process is not without challenges. The initial setup can be time-consuming. Some manufacturers may struggle with the costs and maintenance involved. Understanding these aspects is essential for companies looking to leverage wire EDM service effectively.

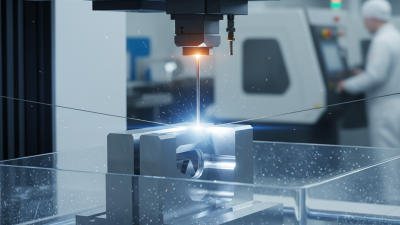

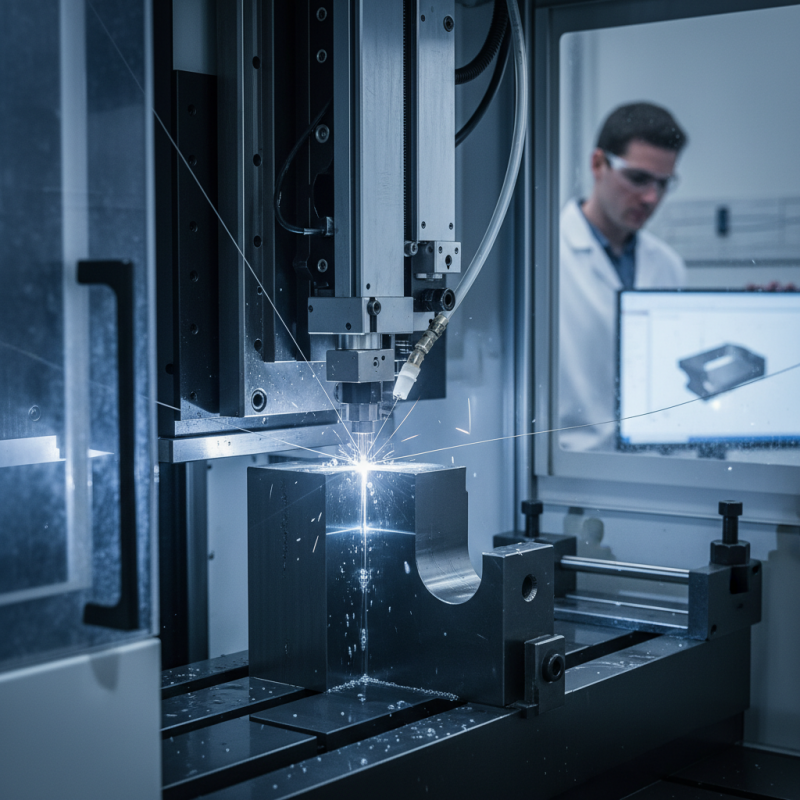

Wire EDM service, or Wire Electrical Discharge Machining, is a precise manufacturing technique. This method uses a thin wire electrode to cut through materials. It performs well on conductive metals, ensuring accurate and intricate designs. The process creates electrically charged sparks between the wire and material. These sparks erode the material, allowing it to take specific shapes.

The versatility of Wire EDM is impressive. It can handle complex geometries that other machining processes struggle with. Industries often use it for aerospace and medical applications. However, it does have limitations. For instance, the process may be slower than traditional methods. It also requires skilled operators to achieve optimal results. The cost can be higher due to the specialized equipment involved.

Despite these challenges, Wire EDM can deliver exceptional precision. It creates smooth surfaces with minimal burrs. This often reduces the need for additional finishing processes. The details achieved in Wire EDM work are remarkable. Yet, mastering this technique takes practice and a willingness to learn from mistakes. It is a constant journey of improvement in the world of advanced manufacturing.

Wire EDM, or Wire Electrical Discharge Machining, operates on the principle of precision cutting through materials using a thin metal wire. This process employs electrical discharges to remove material, allowing for intricate designs and tight tolerances. According to a report by Grand View Research, the global market for EDM techniques is projected to reach USD 9.6 billion by 2025, reflecting its increasing relevance in manufacturing.

The core principle hinges on the gap between the wire and the workpiece. This gap must be maintained to ensure effective cutting. A recent study indicated that even minor deviations in wire positioning can result in significant inaccuracies in the final product. This effect underscores the need for continuous monitoring and adjustment during machining. Operators must remain vigilant, as programming errors can also lead to costly mistakes and waste.

Evaluating the efficiency of Wire EDM reveals mixed results. While it allows for high precision, the process can be slow compared to traditional machining, especially for larger parts. In some cases, the operational costs may outweigh the benefits, pushing manufacturers to reconsider their approaches. Ongoing research could improve speed and cost-effectiveness, yet the current limitations pose challenges. The method's effectiveness relies heavily on skilled technicians who can navigate its complexities with precision.

Wire EDM, or Wire Electrical Discharge Machining, is a precise manufacturing process. Its key applications span various industries, including aerospace, automotive, and electronics. This technology utilizes a thin, electrically charged wire to cut through conductive materials. The process allows for intricate designs and tight tolerances, which are often hard to achieve with traditional machining methods.

In aerospace, Wire EDM is crucial for creating complex components. Parts like turbine blades and engine housings require high precision. This method reduces material waste and enhances efficiency. In the automotive sector, it shapes intricate molds and dies. Manufacturers rely on Wire EDM for its accuracy and ability to handle hard materials.

However, Wire EDM has its limitations. The speed of the process can be slower compared to other methods. It may not be suitable for all materials. Some users have expressed the need for better operator training to optimize results. Despite these challenges, Wire EDM continues to play a vital role in modern manufacturing. Its potential for innovation keeps pushing boundaries.

Wire EDM, or Electrical Discharge Machining, involves a unique process that uses electrically charged wires to cut through metal with precision. The process starts with the setup of the machine and materials. Operators secure the workpiece and install a thin wire, typically made of brass or copper.

During the machining process, a high-frequency electrical current passes through the wire. This creates an arc that erodes the material, shaping it according to the desired specifications. A common setting involves a gap of just 0.001 inches between the wire and the workpiece. This fine gap results in high accuracy, even with complex designs. Industry reports indicate that wire EDM can achieve tolerances of ±0.0001 inches, making it ideal for intricate components.

Tips: Ensure the wire is properly tensioned to avoid breakage. Regular maintenance of the machine enhances its longevity and precision.

The process requires the careful management of parameters like voltage and pulse duration. Finding the right balance can be challenging. Additionally, changing the workpiece material may require adjustments to these settings. Not all materials may yield the same results, leading to trial and error. Operators must remain vigilant to ensure optimal outcomes.

| Process Step | Description | Materials Suitable | Advantages |

|---|---|---|---|

| 1. Setup | Preparation of the machine and workpiece, including fixture installation. | Metal materials such as steel, copper, and brass. | Allows for precise cutting and easy material handling. |

| 2. Wire Feeding | Continuous feeding of the wire electrode into the machining area. | Alloy metals and some plastics. | Minimizes wear on the wire and keeps production efficient. |

| 3. Machining | The actual cutting process using electrical discharges between the wire and the workpiece. | Tough materials such as tool steels and carbide. | Highly accurate and complex shapes can be achieved. |

| 4. Wire Replacement | Replaces the wire after it has been used and worn out. | Widely applicable across different materials. | Ensures ongoing accuracy and efficiency in production. |

| 5. Finishing | Post-machining processes including cleaning and inspection of the finished part. | Any metal workpiece that has been machined. | Assures high quality and readiness for final assembly. |

Wire EDM service offers precision cutting for various materials, like metals and plastics. This process involves using a thin, electrically-charged wire to cut intricate designs. It’s particularly beneficial for parts that require high tolerances. Many industries rely on this technology for components in aerospace and medical applications.

Choosing Wire EDM services comes with several advantages. The process minimizes material waste, which can be more sustainable. It also allows for complex shapes that traditional machining can’t achieve. However, there are considerations. The setup costs can be high, and not all designs work well with Wire EDM. Maintenance of the equipment is essential to avoid errors in production. Understanding these factors helps businesses make informed decisions.